Choosing the best fashion brand knitwear partner can help your brand thrive. You need good quality, trust, and a team you can rely on. Many brands face challenges such as:

Sourcing top yarns and maintaining consistency

Finding fibers that are ethically sourced and come from reputable places

Managing order sizes that align with your needs

Ensuring that sustainability and fairness remain a priority

You should have a partner who understands your requirements. Get ready for straightforward tips and checklists to help you choose with confidence.

Key Takeaways

Make sure you know what knitwear you need. Decide on styles, materials, and order sizes before you look for a partner.

Use online lists and B2B websites to find good manufacturers. These sites let you compare choices easily.

Ask important questions when you check out manufacturers. Ask about minimum order amounts, prices, and what makes them special.

Ask for samples to check quality and skill. Samples show if the manufacturer meets your needs.

Look for certifications that prove quality and care for the planet. Find labels like GOTS and OEKO-TEX to make sure they follow good rules.

Keep talking with your manufacturer often. Give clear feedback and get updates to build a strong team.

Try small orders first to test the manufacturer’s skills. This way, you can see how they work before you order more.

Do good research to avoid mistakes. Make sure the manufacturer knows knitwear and matches your quality needs.

Define Your Knitwear Needs

Before you look for a fashion brand knitwear partner, know what your brand needs. This step helps you stay clear and avoid mix-ups later. It also helps you find a manufacturer who matches your goals.

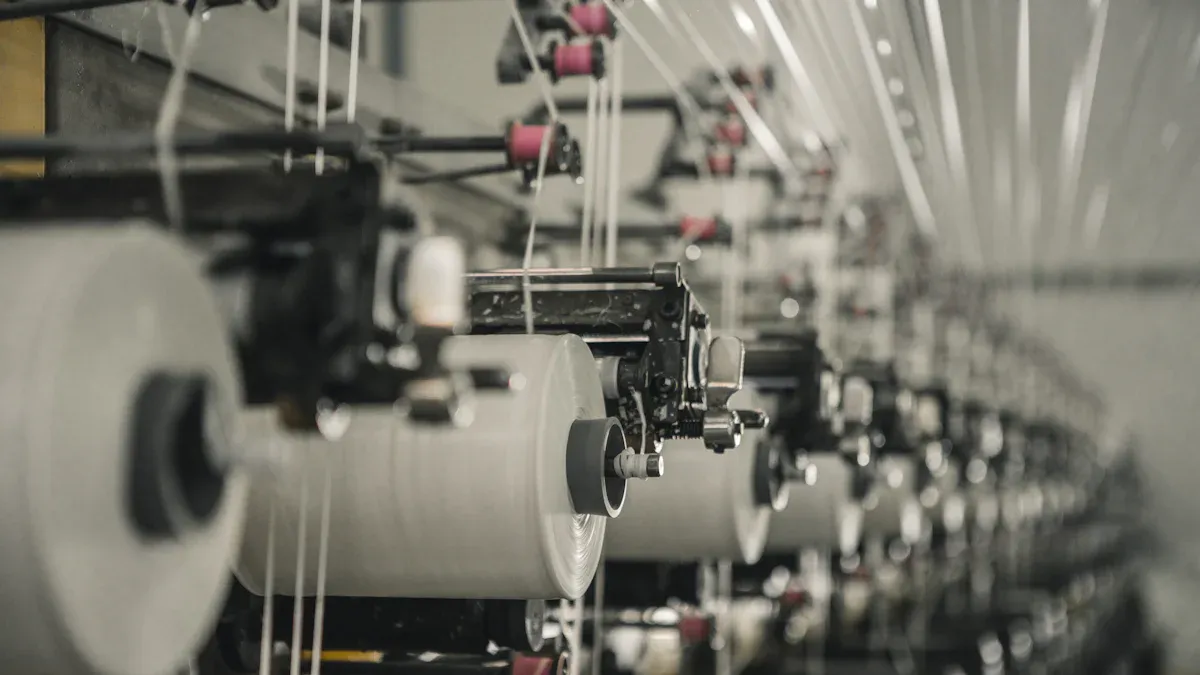

Product Types & Styles

You might already picture your collection. Do you want classic sweaters, trendy cardigans, or bold statement pieces? Knitwear comes in many shapes. Knowing your favorite styles will help you choose.

Here’s a quick look at common knitwear categories:

Category | Examples |

|---|---|

Weft Knit | Jersey, Rib-Knit, Interlock Knit |

Warp Knit | Tricot Knits, Raschel Knits |

Other Styles | Cable Knit, Jacquard Knitting |

Material Preferences

Think about the yarns and fibers you want. Do you like organic cotton, merino wool, or recycled blends? Your choice changes how your products feel, look, and cost. Some manufacturers work with certain fibers. Know what you want before you contact them.

Design Complexity

Are your designs simple or do they have lots of patterns and textures? Complex designs need special machines or skilled workers. Show your ideas and sketches to possible partners. See if they can handle your details.

Production Volume

How many pieces do you want for each style? Your order size helps you pick the right manufacturer.

Small vs. Large Orders

Check if a manufacturer can make the number of pieces you need now and later.

Find partners who have worked with brands like yours.

Ask about their setup and see if it fits your order size.

Quality Standards

Quality is very important in fashion. You want every piece to look good and last long. Setting clear standards helps you avoid problems.

Testing & Compliance

Quality control keeps your clothes free from mistakes and up to standard.

Good manufacturers check fabrics, run lab tests, and approve samples before making your order.

During production, they look for problems at different steps.

After making your clothes, they check packing, finishing, and do final checks to make sure everything is right.

Tip: Make a checklist for your product types, materials, order sizes, and quality standards. This list helps you compare manufacturers and stay organized.

Checklist for Your Knitwear Needs:

What styles and categories do you want?

Which materials fit your brand?

How complex are your designs?

What is your ideal order size?

What quality checks do you expect?

Take time to figure out these needs before you start searching. You’ll save time and find a fashion brand knitwear partner who matches your vision.

Sourcing Fashion Brand Knitwear Partners

To find the right fashion brand knitwear partner, you need to know where to look. There are many places to search, both online and offline. Let’s talk about some good ways to find reliable manufacturers for your brand.

Online Directories & Platforms

You can use online directories and platforms to start your search. These websites help you connect with manufacturers from many countries. They let you compare choices and pick partners who fit your needs.

B2B Marketplaces

B2B marketplaces show you lots of knitwear factories. These platforms have tools that help you feel sure about your decision. Here is a quick table of what you might see:

Feature | Description |

|---|---|

Trusted Factory Network | Global knitwear manufacturers are chosen for quality and flexibility. |

Quality Assurance | Factories are checked and pass special inspections. |

Customization Options | You can pick different yarns and styles for your designs. |

Low MOQs | You can order as few as 100 units per style. |

Managed Production | Communication and tracking help stop problems during production. |

Consistent Quality | Careful checks make sure every piece looks the same. |

You can find trusted factories for custom sourcing and production. Many let you order small amounts, starting at 100 units per style. You also get help from design to delivery, so you know what to expect.

Manufacturer Websites

You should also look at manufacturer websites. Many factories show their work and share reviews from clients. They list what they do best. You can contact them for more details or ask for samples. Look for clear info about their experience, materials, and how they make products.

Trade Shows & Associations

Trade shows and industry associations let you meet manufacturers in person. These events help you build relationships and see products up close. You also learn about new trends and technology in knitwear.

Regional & International Events

You can go to trade shows in your area or in other countries to find new partners. These events bring many suppliers together. You can check quality, ask questions, and watch live demos. Associations often have networking times, so you can meet good manufacturers.

Networking & Referrals

Sometimes, people you know can help you find the best partners. Networking and referrals can lead you to trusted manufacturers you might not find online.

Industry Contacts

Referrals from other designers often lead to reliable partners.

Fashion forums and groups can help you find special partners.

Professional referrals tell you about the strengths and weaknesses of manufacturers.

Tip: Ask your contacts about their experiences with different manufacturers. You might find a great partner or avoid a bad one.

Take time to check these sources. You will find more choices and make better decisions for your brand.

Evaluating Manufacturers

You need to make sure your fashion brand knitwear partner is a good match. This step helps you avoid problems and keeps your brand safe. Let’s look at what you should ask and check.

Key Questions to Ask

When you talk to manufacturers, ask important questions. Here are five questions you should always ask:

What does the cost include?

What makes your company special?

What extra services do you offer?

How do you want to be paid?

These questions help you see if the manufacturer fits your needs. You learn about their process, prices, and what makes them different.

Minimum Order Quantity (MOQ)

Ask about the smallest order you can place. Some manufacturers work with small brands. Others want big orders. Make sure their MOQ matches your plan. If you want to grow, ask if they can handle bigger orders later.

Cost Breakdown

Get a clear cost breakdown. Ask about yarn, labor, packaging, and shipping. This helps you see where your money goes. You can compare prices and find hidden fees.

Experience & Reliability

You want a manufacturer with experience and a good history. Reliable partners help your brand grow and avoid trouble.

Past Work & References

Ask for samples and look at their past work. Good manufacturers share references from other brands. You can see their style and quality. You can also talk to other clients to learn about their experience.

Here’s a table to help you check their experience and reliability:

Criteria | Description |

|---|---|

Quality and Craftsmanship | Do their products look and feel great? Will they last? |

Can they make your designs and meet your needs? | |

Production Capacity | Can they make enough pieces and deliver on time? |

Sustainability Practices | Do they care about the environment and use ethical methods? |

Pricing and Cost Efficiency | Do you get good value for your money? |

Tip: Always ask for samples before you choose. Samples show you the real quality and help you avoid mistakes.

You should also do some research. Check their background and see how they talk to you. Good customer service makes your job easier.

Certifications & Sustainability

Many brands want to work with manufacturers who care about the planet. Certifications show that a manufacturer meets high standards.

Quality Assurance

Look for certifications like OEKO-TEX, ECOCERT, and Cradle to Cradle Certified™. These show that the manufacturer tests their products and follows safe methods. You want your knitwear to be safe and high quality.

Eco-Friendly Practices

Ask about their eco-friendly practices. Do they use recycled yarns? Do they follow the Higg Index from the Sustainable Apparel Coalition? These steps help your brand stay green and responsible.

These certifications matter because they prove the manufacturer cares about the environment and people. They cover things like safe materials, fair labor, and ethical sourcing.

Checklist for Evaluating Manufacturers:

Do they meet your quality standards?

Can they handle your order size?

Do they offer customization?

Are they sustainable and certified?

Is their pricing clear and fair?

Are they in a location that works for you?

Note: Always ask for samples and check references before you pick your fashion brand knitwear partner. This helps you make a smart choice and keeps your brand strong.

Assessing Samples & Communication

When you choose a knitwear partner, you want to see real samples before you commit. Samples show you the quality, style, and skill of the manufacturer. You also learn how well they listen and respond to your feedback.

Sample Orders

Ordering samples is a smart move. You get to touch, see, and test the product before making a big order. Most manufacturers have a set time for making samples. Some work fast, while others take longer.

Here’s a quick look at average turnaround times:

Manufacturer | Average Turnaround Time |

|---|---|

Knitwise | 2–4 weeks |

HEM APPAREL | 8–12 weeks |

You can use this table to plan your timeline. If you need samples quickly, ask about their process before you order.

Craftsmanship Review

When you get your samples, check the craftsmanship. High-quality knitwear stands out. Look for these signs:

Premium, natural fibers like superfine merino wool or grade A cashmere

Construction methods such as fully fashioned and hand-linked techniques

Smooth, even stitches with no loose threads

Final washing and finishing that keeps the shape and prevents shrinking

The way a piece is made matters. Fully fashioned and hand-linked knitwear lasts longer and looks better than cut-and-sew pieces. You want your brand to shine, so pay attention to these details.

Consistency Check

Check more than one sample if you can. Consistency is key. Each piece should look and feel the same. The color, size, and stitching should match your design. If you see big differences, ask the manufacturer why. Consistent samples show that the factory can handle your order without surprises.

Feedback & Revisions

You might want changes after you see your samples. Giving feedback helps you get the product you want. The way you share your thoughts makes a big difference.

Communication Process

Clear and open communication leads to better results. Here’s a table to help you structure your feedback:

Key Aspect | Importance |

|---|---|

Helps you share specific feedback and requests. | |

Collaboration | Builds understanding between you and the manufacturer. |

Precision in Craftsmanship | Makes sure details like stitching and patterns are just right. |

Tip: Write down your feedback. Use photos or sketches to show what you want. Ask questions if you don’t understand something.

Work together with your manufacturer. When you both listen and share ideas, you get better knitwear. Good communication saves time and avoids mistakes.

You can ask for a second sample if needed. This step helps you see if the changes work. Don’t rush this part. Taking time now means fewer problems later.

Final Selection & Negotiation

You’ve compared samples and checked communication. Now, you’re ready to make your final choice. This step is where you set the rules for working together. You want clear terms, fair prices, and a smooth start to your partnership.

Terms & Pricing

You need to understand how pricing works before you sign anything. Manufacturers use different terms for costs and prices. Here’s what you’ll see most often:

Cost of a garment: This is what it takes to make one piece. It covers materials, labor, and overhead, but not profit.

Price of a garment: This is what the manufacturer charges you. It includes their costs and a profit margin.

Wholesale price: This is what you pay if you buy in bulk. It’s lower than the retail price and includes a small profit for the manufacturer.

Retail price: This is what your customers pay in stores. It includes your markup and covers all your expenses.

You should ask for a clear breakdown. Make sure you know what you’re paying for. If you don’t understand a charge, ask questions. You want to avoid surprises later.

Payment & MOQ

Payment terms and minimum order quantities (MOQ) can change from one manufacturer to another. Some want a deposit before they start. Others ask for full payment before shipping. You should agree on a schedule that works for both sides.

Ask these questions:

What is the MOQ for each style?

When do you need to pay?

Can you pay in parts, or do you need to pay all at once?

What happens if you need to change your order?

Write down all agreements. This helps you avoid confusion and keeps everyone on the same page.

Communication & Responsiveness

Good communication makes everything easier. You want a partner who answers quickly and clearly. This helps you avoid mistakes and keeps your project on track.

Here’s why responsiveness matters:

Fast replies help you solve problems before they grow.

Clear answers keep your ideas and the manufacturer’s work in sync.

Quick feedback means fewer delays and better results.

Delays in messages can slow down production and hurt your sales.

Good communication helps you stick to your schedule and meet your goals.

Language & Time Zones

You may work with manufacturers in other countries. Language and time zones can make things tricky. Here’s how you can handle it:

Use simple words and short sentences in emails.

Confirm important details in writing.

Set regular meeting times that work for both sides.

Use tools like email, chat apps, or video calls to stay connected.

If you notice slow replies, talk about it early. You want to fix problems before they affect your orders.

Trial Orders

You don’t have to start with a big order. Many brands test new partners with a small batch. This lets you see how the manufacturer works before you commit.

Trial orders help you:

Check quality on a real production run.

Test how well the manufacturer follows your instructions.

See if delivery times match what you need.

Initial Production Monitoring

When you place your first order, keep a close eye on the process. You want to catch mistakes early. Here’s a simple way to manage your trial order:

Step | Description |

|---|---|

1 | Learn how the negotiation works and who is involved. |

2 | Talk often and clearly at every stage. |

3 | Approve samples before full production starts. |

4 | Fix any problems with samples right away. |

5 | Make sure samples ship on time for your review. |

Stay involved during production. Ask for updates and photos. If you see a problem, speak up fast. This helps you build trust and sets the tone for your future work together.

Tip: Start small, communicate often, and review every step. This approach helps you find the best fashion brand knitwear partner for your business.

Tips & Mistakes to Avoid

Choosing a knitwear partner can feel tricky. You want to avoid common mistakes and make smart moves. Here’s how you can stay on track.

Do’s & Don’ts

You can set yourself up for success by following a few simple rules. Let’s break them down.

Due Diligence

Take your time to check every detail. Don’t rush. Here’s what you should do:

Pick a factory that knows knitwear, not just any garment maker.

Research and compare different factories. Ask for proof of their work.

Look for special incentives or services that fit your needs.

Make sure the factory can show you their certifications, like GOTS or Oeko-Tex.

Ask about their sampling process and see real samples before you decide.

Tip: Always ask for a full cost breakdown before you sign anything. This helps you see where your money goes.

Avoiding Overpromising

It’s easy to get excited and promise too much. Try to stay realistic. Here are some things to avoid:

Don’t choose a factory just because they offer low minimum orders or reply fast online.

Stay away from factories that claim to do everything, like marketing or shipping, not just manufacturing.

Don’t skip fabric research or tech packs. These steps help you get the product you want.

Avoid rushing the sampling process. Good things take time.

Don’t work with factories that won’t answer your questions or show you their work.

Common Mistakes to Watch Out For:

Picking a general garment factory instead of a knitwear specialist.

Ignoring minimum order quantities (MOQs).

Overlooking in-house sampling.

Forgetting about certifications.

Not knowing where the yarn comes from.

Weak quality control.

Poor or missing tech packs.

No fabric research.

Choosing based only on low MOQs or fast replies.

Rushing samples.

No independent quality checks.

Bad payment terms.

Note: If something feels off, trust your gut and ask more questions.

Decision Checklist

Before you make your final choice, use this checklist. It helps you cover all the important points.

Checklist Item | Description |

|---|---|

Can the factory make your styles at the right quality and volume? | |

Do they have strong checks during production? | |

Communication Protocols | How do they share updates and solve problems? |

Production Load | Can they fit your order into their schedule? |

Certifications | Do they have certifications like GOTS or Oeko-Tex? |

Problem Resolution Process | How do they fix mistakes during or after production? |

Sampling Process | What is their sample timeline and cost? |

Next Steps | What info do they need for a quote? What are the next steps? |

Take this checklist with you when you talk to factories. It keeps you organized and helps you make the best choice for your brand.

Remember: Careful planning now saves you time, money, and stress later. You’ve got this! 🚀

Building Long-Term Partnerships

Setting Expectations

You want your knitwear partnership to last a long time. Start by making your expectations clear from the beginning. This helps you and your manufacturer work well together. When everyone knows what to expect, you avoid confusion and mistakes that cost money.

Here are some good ways to set expectations:

Pick partners who care about quality, sustainability, and reliability. These things help your brand grow strong.

Decide on yarn sourcing and production timelines early. These choices change your brand’s quality and future.

Don’t just look for the cheapest price. Focus on quality control to stop defects and delays.

Use flexible logistics. This helps you handle inventory and changes easily.

Work with more than one supplier if you can. Having more options lowers risks and keeps your production flexible.

Setting expectations is more than making rules. It helps build trust and makes sure everyone wants the same things.

Ongoing Communication

Good communication keeps your partnership strong and healthy. You need to talk often and share updates. This builds trust and helps you fix problems before they get big.

Here are ways to keep communication open:

Have regular meetings with your manufacturer. Use video calls, emails, or chat apps.

Share your market ideas and listen to theirs. You both learn and get better together.

Make your brand standards clear. Show what makes your designs special. Your unique details help your products stand out.

Take time to learn about your partner’s culture and style. This makes working together easier.

Talk clearly about terms. Discuss quality, pricing, and timelines so there are no surprises.

When you keep communication open, you build a partnership that lasts. You both win when you work together as a team.

Planning for Growth

You want your brand to get bigger. Your manufacturer should grow with you. Planning for the future helps you both do well.

Try these ideas for growth:

Work closely with your manufacturer. Build trust and share your values.

Look for ways to make your process better. This helps you make more products when you need to.

Keep your client list mixed. This protects you if one market slows down.

Use strong quality control and clear communication. These systems help you grow without losing quality.

Stay flexible with your designs. Watch trends and be ready to change quickly.

“Winning a client is only half the battle. The real challenge—and opportunity—is to turn that relationship into a partnership built on trust, quick responses, and growing together.”

When you plan for growth together, you help your brand succeed for a long time. Your knitwear partner becomes part of your story.

You can find a good fashion brand knitwear partner if you follow easy steps and use helpful checklists. Take your time to check if the designs are right, how fast you get samples, and if the quality stays good when you make more pieces. Make strong friendships with your partners and talk to them often. If you use great materials, care about the planet, and listen to what customers say, your brand will grow faster. Are you ready to begin? Start looking for partners who share your values or check if your current ones are a good fit.

Description | |

|---|---|

3D Technology | Makes design and fit changes faster |

Pima Cotton | Makes collections feel fancy and special |

Customer Feedback Rate | 85%+ means people trust and like the brand |

FAQ

How do I know if a knitwear manufacturer is right for my brand?

You should check their past work, ask for samples, and talk to other brands they work with. Make sure they understand your style and quality needs.

What is a tech pack, and do I need one?

A tech pack is a guide for your design. It shows details like size, color, and materials. You need one to help the manufacturer make your product just right.

Can I order small quantities when starting out?

Yes, many manufacturers offer low minimum order quantities (MOQs). Always ask about their MOQ before you start. This helps you avoid surprises.

How long does it take to get samples?

Sample times can change. Some factories send samples in 2–4 weeks. Others may take longer. Ask your manufacturer for their timeline before you order.

What certifications should I look for?

Look for certifications like GOTS, OEKO-TEX, or BSCI. These show the factory cares about safety, quality, and fair work.

How do I handle problems with my order?

Stay calm and talk to your manufacturer right away. Share photos and details. Good partners will help fix mistakes quickly.

Can I visit the factory before placing an order?

You can ask to visit. Many manufacturers welcome visits. Seeing the factory helps you trust their work and understand their process.