When you look for a nylon blend knitwear manufacturer, you should think about four main things:

Quality: See if the products are good enough for you.

Customization: Make sure you can make special styles for your brand.

Sustainability: Pick materials that are good for the earth and made fairly.

Reliability: Work with someone who is on time and talks to you clearly.

Tip: Always check if these things fit what your brand wants and needs.

Key Takeaways

Figure out what your brand needs before you look for a manufacturer. This helps you find the right partners.

Think about quality, customization, sustainability, and reliability when picking a nylon blend knitwear manufacturer.

Look up manufacturers in online lists and at trade shows to find good partners.

Check if the manufacturer can make enough products and deliver on time. This makes sure they can meet your needs.

Ask for samples to see if the quality and look are the same before you order a lot.

Choose manufacturers who use eco-friendly methods and have certifications. This matches your brand’s values.

Talk clearly and set rules to build a good partnership with your manufacturer.

Compare prices and extra benefits to make sure you get the best deal for your brand.

Define Brand Needs

Before you start searching for a nylon blend knitwear manufacturer, you need to know what your brand wants. This step helps you focus on the right partners and avoid costly mistakes. Take time to write down your goals and must-have features for your knitwear line.

Product Vision

Style and Function

Think about the look and feel you want for your products. Do you want classic sweaters, sporty pullovers, or trendy cardigans? Decide if your knitwear should be soft and cozy, lightweight and breathable, or strong and stretchy. Make a list of the main styles and functions you want. This will help you explain your ideas to manufacturers.

Target Market

Ask yourself who will wear your knitwear. Are you designing for teens, adults, or kids? Do your customers care about fashion, comfort, or performance? Knowing your target market helps you choose the right materials and designs. It also helps you set the right price and quality level.

Technical Specs

You need to know the technical details for your nylon blend knitwear. These details guide the manufacturer and make sure you get the results you want.

Here is a table of common technical specifications for nylon blend knitwear:

Specification | Details |

|---|---|

Fiber type | Nylon 6, Nylon 6,6, or rPA |

Blend ratio | 85/15 or 80/20 with spandex |

Denier | 40D–210D depending on use |

GSM | 100–250 GSM common |

Certifications | OEKO-TEX®, GRS, etc. |

Nylon Blend Ratios

Choose the right blend ratio for your needs. A higher nylon content gives more strength and stretch. Adding spandex makes the fabric more flexible. Pick a blend that matches your product vision and customer needs.

Performance Features

Decide which features matter most. Do you want moisture-wicking, quick-dry, or anti-pilling properties? List these features so you can ask manufacturers if they can deliver them.

Budget and Timeline

Set a clear budget for your project. Know how much you can spend on each piece and for the whole order. Make a timeline for your launch. Write down when you need samples, production, and delivery. This helps you evaluate key factors like cost, speed, and reliability when you talk to manufacturers.

Tip: Write down your must-have features and desired outcomes before you contact any manufacturer. This makes your search faster and more successful.

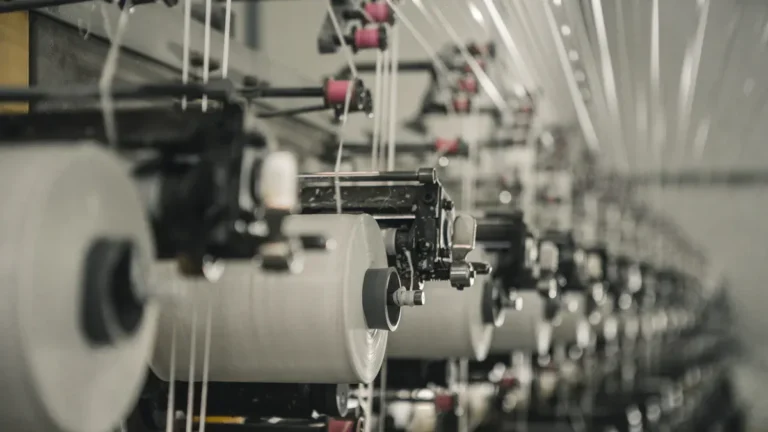

Research Nylon Blend Knitwear Manufacturer Options

You need to pick the right manufacturer for your nylon blend knitwear. Start by looking at different ways to find them. This helps you find good partners and see what each one is good at.

Sourcing Channels

Online Directories

Online directories make searching easier. You can use websites like Alibaba, Maker’s Row, or Kompass. These sites help you find manufacturers from all over the world. You can sort by what they make, where they are, and their certifications. You can also read reviews and see ratings from other brands. This helps you stay away from risky choices and focus on trusted suppliers.

Tip: Always check if the manufacturer makes nylon blend knitwear. Look for clear product details and photos.

Trade Shows

Trade shows let you meet manufacturers in person. Events like Première Vision, Texworld, or local textile expos are good places to go. You can see samples and ask questions right away. You can compare quality and talk about your needs face-to-face. Many brands find new partners at trade shows. They can touch the fabrics and see new trends.

Here is a table that shows where nylon blend knitwear manufacturers are and what they do best:

Country | Specializations | Key Regions | Additional Insights |

|---|---|---|---|

China | 210D–1680D coated nylon, ripstop, camouflage | Guangdong, Zhejiang | Fast prototyping (3–7 days), strong export experience |

India | Nylon-cotton blends, organic-certified fabrics | Gujarat, Tamil Nadu | Eco-conscious options, popular with UK buyers |

Turkey | Stretch nylon for athleisure, breathable laminates | Istanbul, Bursa | High compliance standards, short EU shipping lead times |

South Korea | Nylon-spandex blends, nanotechnology coatings | Seoul, Daegu | Exports technical nylon fabrics to North America and Europe |

Shortlisting

After you make a list of manufacturers, you need to narrow it down. Focus on where they are and how good their reputation is.

Location

Location changes shipping costs and how you talk to them. If you want fast shipping to the US or Europe, try Turkey or South Korea. China is good for quick samples and big orders. India is great for eco-friendly choices and brands that care about the earth. Pick a place that fits your budget and schedule.

Reputation

Reputation is important when you choose a manufacturer. Brands check reviews, ask for references, and look at past work. You want a partner known for good quality and being reliable. Use this table to help you make your shortlist:

Criteria | Description |

|---|---|

Quality & Craftsmanship | Find manufacturers known for high-quality products. |

Materials & Sustainability | Pick manufacturers with eco-friendly options if you care about the earth. |

Production Capacity | Make sure they can handle your order size, big or small. |

Customization & Design Support | Some manufacturers help you improve your designs. |

Lead Times & Reliability | On-time delivery is important; ask about how long production takes. |

Pricing & Costs | Compare prices to fit your budget but keep good quality. |

Location & Logistics | Think about shipping costs and how easy it is to talk to them. |

Note: Always ask for samples and check references before you decide. This helps you avoid problems and makes sure your brand gets the best results.

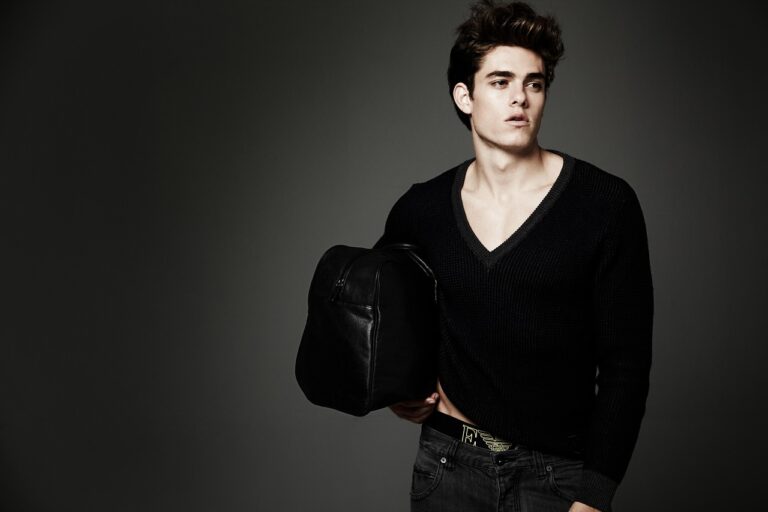

Evaluate Quality and Customization

When you pick a nylon blend knitwear manufacturer, you should think about quality and customization. These two things help your brand stand out. They also make your customers happy. You want every item to match your ideas and be just what you expect.

Quality Control Processes

Quality control is very important for any knitwear brand. You need to know how your manufacturer checks quality at each step. This helps you avoid problems. It also makes sure your products are always good.

Sample Review

You should ask for samples before you order a lot. Samples help you check the fabric, stitching, and look. The best manufacturers use strong quality control steps. This makes sure you get what you want. Here is a table that shows the main steps for quality control:

Quality Control Stage | Description |

|---|---|

Pre-Production Inspection | Check raw materials for problems. Make sure color, texture, and strength are right before making anything. |

Inline Inspection | Watch the clothes during making. Catch mistakes early, like bad stitching or missing parts. |

Final Inspection | Check finished products for size, color, and safety before sending them out. |

You should see if your manufacturer uses these steps. Many top factories use AATCC textile testing and ISO quality systems. These systems help keep quality high. They make sure every batch is just what you need.

Tip: Always look at samples for color, fit, and feel. This helps you find problems before making a big order.

Consistency Checks

You want every order to be as good as your first sample. Consistency checks help you get the same quality every time. Good manufacturers use many ways to keep quality steady:

Fabric package testing checks color, strength, and size.

Garment package testing checks fit, seams, and how clothes look after washing.

Proactive quality assurance starts at the spinning place and checks every step.

Working with trusted suppliers, like UV Exports, gives you certified performance knits.

Strong supply chain management keeps quality high and delivery on time.

These steps help you trust your knitwear will always be good. You can ask your manufacturer about their quality control and how they keep quality steady for every order.

Customization Flexibility

Customization helps your brand make special products. You want a manufacturer who gives you lots of choices and listens to your ideas. This helps you build a collection that matches your vision and fits your customers.

Design Options

You can pick from many design options with a good nylon blend knitwear manufacturer. Here is a table that shows some popular choices:

Customization Type | Minimum Order | Description |

|---|---|---|

100 pieces | Lets you add special graphic designs to your knitwear. | |

Customized packaging | 100 pieces | Lets you choose special packaging for your products. |

Customized logo | 100 pieces | Lets you put your brand logo on the knitwear. |

You can make custom collections for your needs. Many manufacturers let you order small amounts, so you can try new ideas without a big risk. If you want to move fast, look for suppliers with short lead times. This helps you keep up with trends and give customers what they want.

Fabric Choices

Fabric choice is important for both quality and customization. You want to use top quality fabrics that feel nice and last long. Many manufacturers offer lots of high quality fabrics, with different nylon blend ratios and finishes. You can pick blends for the right stretch, softness, or strength. Some suppliers even have eco-friendly options to match your brand’s values.

Note: Always ask about fabric choices and get swatches. This helps you see and feel the quality before you choose.

When you focus on quality control and customization, your brand can do well. You get products that look nice, feel good, and meet your standards every time.

Assess Production Capacity and Lead Times

When you pick a nylon blend knitwear manufacturer, you should check how much they can make and how fast they deliver. These things help you avoid waiting too long and help your brand grow well.

Order Volume

Minimum Quantities

Manufacturers usually have a smallest order size. You need to ask about this before you start. Some factories work with small brands and let you order less. Others want you to order a lot at once. If you want to try new styles or start small, find a partner who lets you order less. This helps you take less risk and have more choices.

Tip: Always check the smallest order size for each style or fabric before you sign anything.

Scalability

Your brand might get bigger later. You need a manufacturer who can make more as you grow. Many factories use smart ways to make more clothes. Here is a table that shows how they do it:

Strategy | Description |

|---|---|

Optimizing production processes | Factories use smart steps to save time and work better. |

Integrating automation and technology | Machines help make clothes faster and easier. |

Investing in skilled labor and training | Workers learn new things to use new machines and ways. |

Strengthening supplier relationships | Factories make friends with suppliers to get materials quickly. |

Focusing on quality control | Computers help keep clothes good and the same. |

You should ask if the manufacturer can make more if you need it. A good partner can grow with you and help you when you need more clothes.

Delivery Schedules

Lead Time Estimates

Lead time means how long it takes to make and send your order. You need to know this so you can plan when to sell your clothes. Most nylon blend knitwear makers tell you how long each step takes. Here is a table that shows how long it usually takes:

Stage | |

|---|---|

Production | 7–14 days |

Shipping – Economy | 7–14 days |

Shipping – Express | 3–5 days |

Total Timeline | 2–4 weeks |

You should ask for a timeline before you order. This helps you plan better and not be surprised.

On-Time Performance

Getting your order on time is very important. You want a manufacturer who always ships when they say. Ask other brands if the factory is on time. Pick partners who give updates and fix problems fast. Good talking and meeting deadlines means the manufacturer cares about your brand.

Note: Always check your orders and ask for updates often. This helps you see problems early and keep your customers happy.

When you check how much a factory can make and how fast they deliver, you make better choices for your brand. You get your clothes on time and help your business grow.

Sustainability and Ethical Practices

When you pick a nylon blend knitwear manufacturer, look at how they help the planet and treat workers. Many brands want to use eco-friendly materials and work with factories that follow good rules. This makes your brand special and helps customers trust you.

Eco-Friendly Materials

There are many green choices for nylon blend knitwear. Recycled nylon is a top pick. It uses old things like fishing nets and plastic from factories. This cuts down on waste and saves resources. ECONYL® is a famous recycled nylon. It works as well as new nylon but comes from trash. Some makers use bio-based yarns, like EVO by Fulgar, made from plants. These materials help the earth by lowering harm.

Certifications

Certifications show a manufacturer cares about the planet. You should ask if they have OEKO-TEX®, GRS, or Better Cotton Initiative. These prove the materials are safe and eco-friendly. Factories often show their certifications on websites or labels. You can use these to compare suppliers and choose the best one.

Certification | What It Means |

|---|---|

OEKO-TEX® | Checks for bad chemicals in textiles |

GRS | Proves recycled content and good production |

BCI | Supports fair cotton farming |

Tip: Always look for certifications before you buy. This helps you know your products are safe and good for the planet.

Sourcing Policies

Ask each manufacturer about their sourcing rules. Some only use recycled or organic materials. Others work with suppliers who follow strict earth-friendly rules. Good sourcing helps you avoid bad chemicals and supports slow fashion. You can ask for a list of materials and where they come from. This gives you more control over your supply chain.

Ethical Manufacturing

Ethical manufacturing means treating workers well and following laws. You want partners who care about people and the planet.

Labor Standards

Factories should pay workers fairly and keep them safe. Some brands, like Knitup, work with good suppliers to make sure everyone is treated right. You can ask about labor standards. Look for clear rules about worker rights and safety. Many brands check factories and talk to workers to support fair rights.

Safe workplaces

Good pay

Compliance

Compliance means following all laws for work and safety. You should check if your manufacturer meets these rules. Many factories share reports and audits to prove it. You can ask for these papers before you start working together. Being open builds trust and helps you avoid trouble.

Note: Ethical manufacturing and strong compliance keep your brand safe and help you grow the right way.

When you focus on sustainability and ethics, you make better choices for your brand. You help the planet, support workers, and earn trust from customers.

Analyze Pricing and Value

When you choose a nylon blend knitwear manufacturer, you need to look at both pricing and value. This helps you understand what you pay for and what you get in return. You want to make sure your brand gets the best deal for your money.

Pricing Structure

Manufacturers use different ways to set prices. You should ask for a clear breakdown of all costs. This helps you compare options and avoid surprises.

Cost Breakdown

You will see that the cost of nylon blend knitwear depends on many things. Raw materials, processing, and fabric type all change the final price. Here is a table that shows common pricing for different fabrics:

Fabric Type | Raw Material Cost (per kg) | Processing Overhead (per kg) | Fabric Pricing (per yard) | Price Premium |

|---|---|---|---|---|

Wool–Nylon (80/20) | Wool: $8–$12, Nylon: $2–$4 | $1.00–$2.00 | $8–$15 | N/A |

Nylon | $2.00–$4.00 | $0.50–$1.00 | $3.50–$8.00 | 20–30% over polyester |

You should ask your manufacturer for a full cost list. This includes raw materials, labor, and any extra fees. Knowing the cost of each part helps you plan your budget. It also helps you see if you are paying too much for any step.

Payment Terms

Payment terms are important for your cash flow. Some manufacturers ask for a deposit before they start. Others want payment when they ship your order. You should ask about payment schedules, accepted methods, and any extra charges. Clear payment terms help you avoid problems and keep your project on track.

Tip: Always get payment terms in writing before you agree to anything.

Added Value

Some manufacturers give you more than just production. You should look for partners who add value to your brand.

Design Support

Many factories help you with design. They can suggest better materials or new styles. For example, some brands work with suppliers who use special yarns like regenerated Econyl nylon. This helps you tell a strong story about your products. You can use these stories in your marketing to connect with your customers.

Partnership Potential

A good manufacturer can become a long-term partner. They may offer help with sourcing eco-friendly materials or improving quality control. Some brands, like Norrona, work with factories that test every batch for strength and durability. This shows the value of a partner who cares about your success. You should look for a manufacturer who supports your growth and shares your values.

Note: Added value can help your brand stand out in a crowded market.

When you compare pricing and value, you make smarter choices for your brand. You see the true cost of each option and find partners who help you grow. Always ask questions about cost, payment, and sourcing before you decide.

Verify Reliability and Communication

When you pick a manufacturer for nylon blend knitwear, you should check if they are reliable. Good communication is also important. These things help you avoid mistakes. They help you trust your supplier. You want partners who meet your needs. You want them to keep you updated all the time.

Reputation Checks

Reviews

Start by reading what other brands say. Reviews tell you if a supplier is on time. They show if the supplier keeps quality good. You can see if they fix problems fast. Look for comments about being reliable. See how they handle issues. Some brands talk about late shipments. Some mention bad quality. Good reviews mean the supplier does what they promise.

You can also look at ratings online. Trade websites show scores for reliability. They show scores for product quality and talking to customers. High scores mean the supplier cares about doing a good job.

References

Ask the supplier for names of past clients. Talking to other brands helps you learn more. Good suppliers give you contact details. You can ask about standards, delivery, and support. When you talk to references, ask these questions:

How does the supplier fix problems?

Does the supplier meet quality standards?

How fast does the supplier answer questions?

You can also ask for proof of testing and certifications. Reliable suppliers use special tests. These tests check nylon/spandex ratios, stretch, and colorfastness. The tests show the supplier meets strict rules.

Communication

Responsiveness

Good suppliers answer questions quickly. They keep you updated often. Fast replies show they care about your business. They follow rules for customer care.

It is important to set clear rules from the start. Talk about quality, delivery times, and payment. This helps you avoid problems and builds trust.

Keep talking with your supplier during the order process. Check in often to stay updated. This helps you fix problems before they get big.

Using technology like emails and video calls makes talking easier. It helps you work better with your supplier.

Suppliers who use emails and video calls make things simple. You can track orders and ask questions. You get updates right away. This helps you find problems early. It keeps your project moving.

Collaboration

Collaboration means working together to fix problems. It helps make products better. Reliable suppliers use smart tools to help you. Here are some ways they help:

Manufacturers use artificial intelligence to make work easier. This helps keep standards high.

The Internet of Things lets suppliers watch production in real time. They can fix things quickly.

Cloud platforms help share information fast. You can make choices and respond to changes.

When you work with suppliers who like teamwork, you get better results. You can change orders and designs together. You can fix issues as a team. This builds a strong partnership. It keeps reliability important for your brand.

By checking reputation and testing, and by talking often, you find good suppliers. You build trust and avoid mistakes. You help your brand grow with reliable partners.

You can find the best nylon blend knitwear manufacturer by using easy steps. First, check if the factory uses good materials. Look at samples to see if the fabric is always the same. Check how much the factory can make and how they set prices. Use this table to help you pick:

Factor | Importance |

|---|---|

Quality Control | Makes sure clothes are made well and meet what people want. |

Production Capabilities | Shows if the factory can make enough for you. |

Pricing Structure | Helps you plan your money and how much to buy. |

Talk to your favorite factories and ask for samples. Tell them what you need and ask questions to build trust.

FAQ

What makes a nylon blend knitwear manufacturer different from others?

Nylon blends make knitwear stretchy and strong. These manufacturers know how to make clothes that last longer. Your brand gets more choices and better performance.

How do you check the quality of knitwear from a manufacturer?

Ask for samples before you buy anything. Look at the stitching and feel the fabric. Check the color to see if it matches. Good manufacturers test their products carefully. Make sure every batch looks and feels the same.

Can a manufacturer help you design custom knitwear?

Yes, many manufacturers help with design. You can share your ideas for patterns and colors. They help you add logos too. Experts in customization guide you through each step.

What is the usual minimum order for knitwear production?

Most manufacturers want you to order at least 100 pieces. Ask each one about their rules. Some let small brands order less.

How long does knitwear production take with a nylon blend knitwear manufacturer?

Production time depends on how much you order and your design. Most orders take two to four weeks. Ask for a timeline before you start.

Why should you choose a manufacturer with sustainability expertise?

You help the earth and your brand. These manufacturers use recycled nylon and green methods. You can sell knitwear that customers want because it is eco-friendly.

What certifications should you look for in a knitwear manufacturer?

Look for OEKO-TEX®, GRS, or BCI certifications. These show the materials are safe and made the right way. Certified manufacturers give you high-quality knitwear.

How do you communicate with a manufacturer during knitwear production?

Use email, phone, or video calls to talk. Good manufacturers answer fast and keep you updated. Ask for progress reports to track your order and fix problems early.

Tip: Always keep records of your talks with the manufacturer. This helps you avoid mistakes and keeps production smooth.

FAQ Topic | Key Point |

|---|---|

Quality | Check samples and consistency |

Customization | Share ideas with manufacturer |

Sustainability | Look for eco-friendly expertise |

Communication | Stay updated during production |