If you’re aiming to ship a men’s cashmere capsule for Fall, the difference between hitting the window and missing it by a week is your calendar discipline. This guide gives you a practical, back‑plannable cashmere sampling timeline you can drop into your Gantt today—built around three common market anchors:

North America DTC launch: mid‑September

Wholesale + DTC deliveries: August–September (FW)

EU deliveries: July–August (earlier intake)

We’ll walk phase by phase—design freeze → proto → SMS (size set) → PP → bulk—with explicit buffers for tests and approvals.

Key takeaways

Work in working days. Plan Proto 5–7 WD, SMS 10–14 D, Bulk 45–60 D, with 3–5 WD buffers at each gate.

Back‑schedule from your delivery week: EU ships earlier (Jul–Aug), wholesale+DTC (Aug–Sep), NA DTC mid‑Sep.

Baseline tests: pilling, shrinkage, color fastness; add a fit check and a full size review before PP.

Use an AQL pre‑shipment inspection (Level II; Major 2.5 / Minor 4.0) to keep quality predictable.

WHOLEGARMENT can remove linking bottlenecks, but you must front‑load programming and yarn approvals.

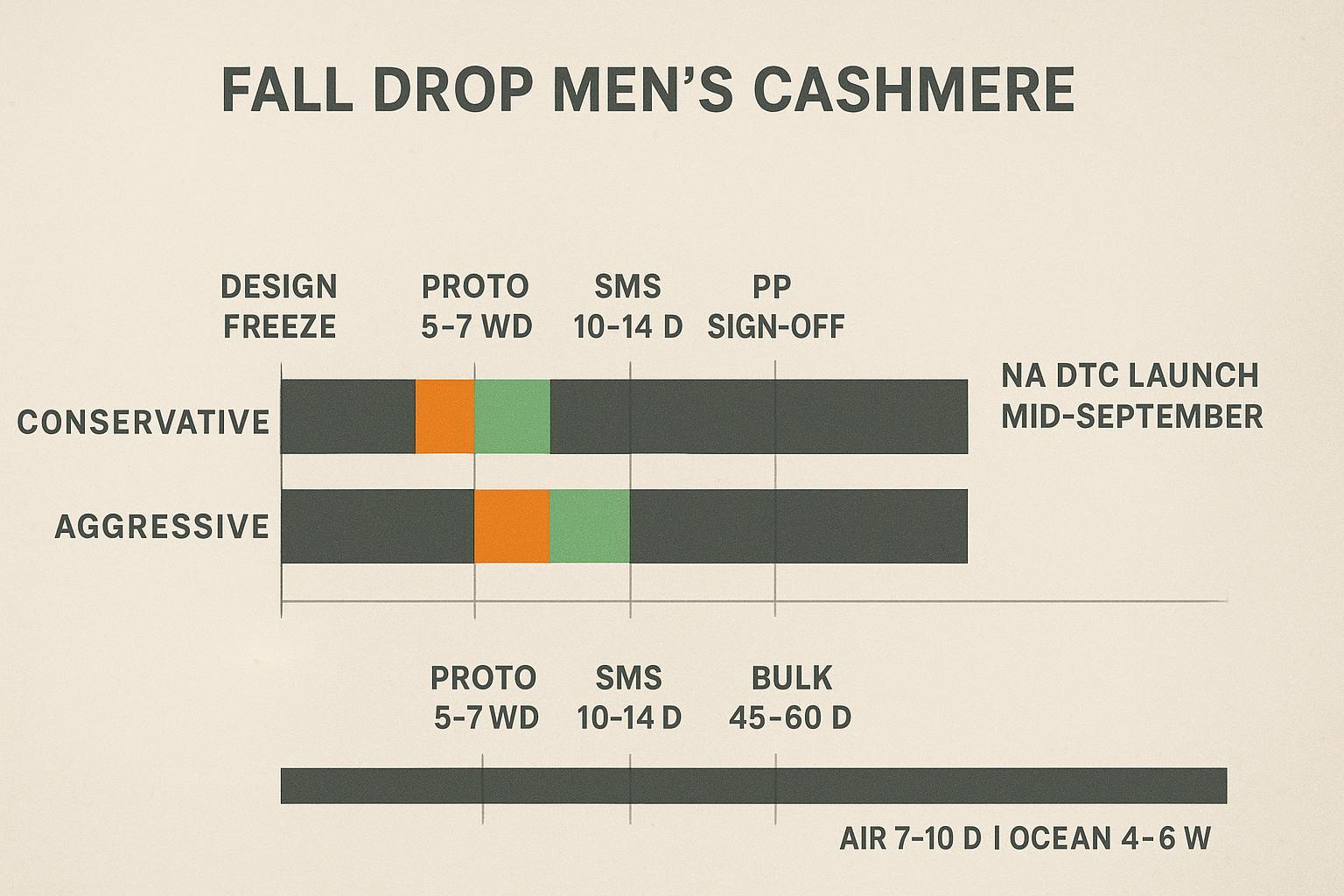

Executive micro‑Gantt: NA DTC mid‑September launch

Conservative track uses the upper bound of each phase plus 5‑day buffers; aggressive uses the lower bound plus 3‑day buffers.

If yarn is pre‑approved and on hand, you can compress Proto (see the quick sampling note below).

Hold a PP sign‑off before committing the bulk knit; book freight early if you’re ocean‑shipping any portion.

Step‑by‑step cashmere sampling timeline (Gantt‑ready)

This section turns the plan into date math you can paste into your project file. The primary keyword “cashmere sampling timeline” appears here because this is where you’ll do the actual scheduling work.

1) Design freeze (set the baseline)

Lock the style list and inputs. Your freeze packet should include a clean tech pack (stitch/gauge, yarn count, target weight), graded measurement chart, finishing notes (wash/steam/block), labeling/packaging specs, and colorways. Confirm yarn availability and lead times. If you intend to use seamless knitting, add programming notes early so shape logic is stable.

Practical tip: When yarn is already in stock and approved, Proto can begin within 24–48 hours; when it isn’t, expect a short wait for cones to be wound and queued.

2) Proto: 5–7 working days (+ 3–5 WD buffer)

Objective: Validate pattern logic, handle, weight, and baseline measurements after finishing. For cashmere, insist on a clearly documented wash/steam/block recipe and record pre‑ and post‑wash measurements.

Compressing this phase: Brands sometimes achieve a 3–5 day proto when yarn is pre‑approved and a prior pattern exists. See this operational overview of quick sampling for what makes fast protos realistic.

Deliverables: 1 proto per style, finishing recipe, measurement sheet, variance notes, and a fit review decision (approve/revise).

3) SMS (size set): 10–14 days (+ 3–5 WD buffer)

Objective: Build a representative size run to confirm grading and fit consistency across sizes. Merge fit learnings into the graded spec; note any cashmere‑specific drape changes post wash/block.

Deliverables: 6–12 pcs covering core sizes, updated graded spec, confirmed tolerances, and a formal size‑set sign‑off.

Global sizing: If you sell into US/EU/Asia, ensure your measurement chart aligns with your target region’s norms; prepare one set of comments per region if needed.

4) PP meeting/sign‑off (gate)

Objective: Freeze machine settings (tension, take‑down, stitch density), finishing parameters, trims, labels, and packing. Record all settings on a PP sheet and bind to the work order. This is the last chance to adjust before volume.

Approvals to verify: fit/measurements, wash/finishing outcome, color shade bands, label/legal copies, care instructions, and carton marks.

5) Bulk production: 45–60 days (+ 3–5 WD buffer)

Objective: Knit, finish, QA, pack. For traditional fully‑fashioned sweaters, plan capacity for linking and hand finishing; for seamless, linking is removed but upfront programming time matters. Book your pre‑shipment inspection and freight.

AQL pre‑ship: Many brands use General Level II with Major 2.5 / Minor 4.0; here’s a practical overview of AQL 2.5 acceptance logic and a handy AQL acceptance calculator.

Shrinkage control: Cashmere demands disciplined wash/block. Review stabilization practices and post‑wash measurement management as outlined in this primer on knitwear washing, blocking, and stabilization.

Durations and buffers at a glance

Phase | Core duration | Typical buffer |

|---|---|---|

Proto | 5–7 working days | 3–5 working days |

SMS (size set) | 10–14 days | 3–5 working days |

Bulk production | 45–60 days | 3–5 working days |

Note: Buffers cover lab tests, approvals, and calendar friction (weekends/holidays). If your factory runs a different shift calendar, convert to calendar days explicitly.

Testing and approval matrix (what to test, when to test, and why)

Pilling resistance: Use Martindale‑based methods (ISO 12945‑2 or ASTM D4970). Method suites are paywalled; review the standard identifiers via the ASTM/AATCC portals. AATCC maintains a searchable index of methods in its standards portal, and Vartest offers a helpful overview hub of ISO/AATCC/ASTM practices.

Dimensional stability (shrinkage): ISO 6330 or AATCC 135 after the factory’s intended wash/block. For cashmere, a planning guardrail is ≤3% change in length/width, unless your brand policy differs.

Color fastness: ISO 105‑C10 (washing) and ISO 105‑X12 (rubbing). Confirm lab dips ahead of SMS.

Approval gates: Fit approval after Proto; size‑set sign‑off after SMS; PP sign‑off before bulk; pre‑ship AQL pass before freight booking.

Here’s the deal: run essential tests at SMS or PP so results reflect the actual finishing route you’ll use in bulk.

WHOLEGARMENT timeline considerations (seamless vs traditional)

Seamless knitting can shorten the overall program by removing panel linking and some assembly steps, but it moves effort earlier in the calendar.

Front‑load programming: Provide stable pattern logic and shape definitions; add a 3–5 WD programming buffer before Proto if the style is new.

Capacity shift: Time you save on linking may be re‑invested in programming and tension trials. For fundamentals on knit machinery and integral/seamless concepts, see CottonWorks’ concise knit machinery overview.

Think of it this way: seamless is like cooking a one‑pot dish—it skips plating steps, but you must prep all ingredients and timing up front.

Practical example: one calendar you can copy

Disclosure: Xindi Knitwear (Knitwear.io) is our product. In practice, we often plan with the following example ranges: Proto 5–7 WD, SMS 10–14 D, Bulk 45–60 D, and 3–5 WD buffers at each gate. For a walk‑through of milestones and shop‑floor handoffs, this neutral explainer of an OEM/ODM knitwear production process can help you map deliverables to dates.

NA DTC mid‑September: Count back 7–9 weeks for bulk + buffers (air for first drop); lock PP by late July; SMS done by mid‑July; Proto by early July; design freeze late June.

Wholesale + DTC deliveries (Aug–Sep): Assume mixed freight—ocean for base lots (book 6–8 weeks earlier), air for first wave. PP no later than early July; SMS mid‑June; Proto early June; design freeze late May.

EU deliveries (Jul–Aug): Earlier retail intake means shifting everything forward ~4–6 weeks. PP by early June; SMS mid‑May; Proto early May; design freeze late April.

Caution: Always validate with your own retail partners—intake calendars vary by region and channel.

Closing: your quick SOP checklist

Freeze styles and yarns early; confirm yarn on‑hand before Proto when possible.

Run Proto with a documented wash/block; approve fit from post‑wash measurements.

Build and sign off a size set; record tolerances; prep for PP.

Hold a PP gate; then run bulk with an AQL Level II pre‑ship booked ahead.

Choose air for time‑critical first drops; book ocean 6–8 weeks earlier for base volumes.

Further reading: If you need a deeper dive on test methods, AATCC’s standards portal and the Vartest overview hub are solid starting points.