Petite cloud sweaters—those airy, lightweight knits with a soft halo and precise drape—are notoriously hard to prototype fast and reproduce at small quantities. This review examines how Xindi Knitwear (our own factory brand) performs for petite cloud sweaters at low MOQs, with an evidence‑first look at sampling speed, fine‑gauge control around ~17 stitches per 10 cm, seamless WHOLEGARMENT feasibility, quality benchmarks, sustainability documentation, and communication cadence.

Key takeaways

3–5 day sampling is available under defined conditions (stock yarns, clear tech pack) and is documented on Xindi’s official Quick Sampling page.

Fine‑gauge control near ~17 sts/10 cm and WHOLEGARMENT (seamless) construction are feasible for petite cloud sweaters; we explain the verification method below.

Low MOQs (typically 50–100 pcs per style/color) are achievable; cost predictability depends on yarn, stitch complexity, and finishing.

Certification bundle (OEKO‑TEX/GOTS/GRS/RWS) can be provided upon request with verifiable chain‑of‑custody references.

A milestone‑based communication cadence keeps cross‑timezone projects on track; we include a practical cadence you can adopt.

Why petite cloud sweaters at low MOQ work

For brands balancing speed and quality, petite cloud sweaters low MOQ projects are about risk control: validate handfeel and fit fast, then scale without overcommitting inventory. Xindi’s approach—rapid prototyping, stitch‑density control, and transparent variables—aims to preserve margin while keeping creative intent intact.

Testing protocol

Environment: 20°C and 65% RH lab conditions; laundering per ISO 6330 / AATCC TM135; colorfastness references AATCC TM61 (laundering) and AATCC TM8/116 (crocking); optional bursting strength via ASTM D3786.

Article under test: Fine‑gauge petite cloud sweater targeting ~17 sts/10 cm; WHOLEGARMENT preferred where scheduling permits.

Sample size guidance: Two prototype iterations minimum; five garments used for laundering tests; three repeated measurements per garment per POM.

Evaluation thresholds: Fit tolerance ±1–1.5 cm on key POMs; post‑wash shrinkage ≤3–6%; pilling grade ≥3 (good ≥4); laundering colorfastness ≥4; dry crocking ≥4 / wet ≥3.

Evidence policy: If a dimension isn’t tested or lacks artifacts, we mark it “Insufficient data.”

References: See standards from the AATCC/ISO/ASTM and WHOLEGARMENT machinery specifications by Shima Seiki.

Verdict and rating snapshot (as of Feb 2026)

Performance & SLA adherence: 4.5/5 — Sampling speed documented at 3–5 days on the official site; first‑pass accuracy depends on brief quality. Evidence: internal pages; artifacts recommended.

Quality & reliability: 3/5 — Strong method and thresholds, but public lab reports are not posted; buyers should request test PDFs. Evidence: standards context; Insufficient data for posted results.

Capability & technology: 4/5 — Fine‑gauge control and WHOLEGARMENT are feasible; machine‑model list not publicly published. Evidence: internal how‑to pages + Shima Seiki docs.

Usability & communication: 4/5 — Practical milestone cadence works cross‑timezone; formal SOP page not public. Evidence: proposed cadence with logs recommended.

Sustainability & certifications: 3/5 — Standards supported; public certificate IDs/PDFs not yet listed on site; available upon request.

Value & cost predictability: 3.5/5 — Low MOQs (50–100 pcs) with transparent variables; no public price list; quotes advised.

Support & after‑sales: 3/5 — No public remake policy; case‑by‑case support.

Overall: 3.8/5 for petite cloud sweaters at low MOQs — especially strong for speed and fine‑gauge execution when paired with clear specs and stock yarns.

How we tested (method overview)

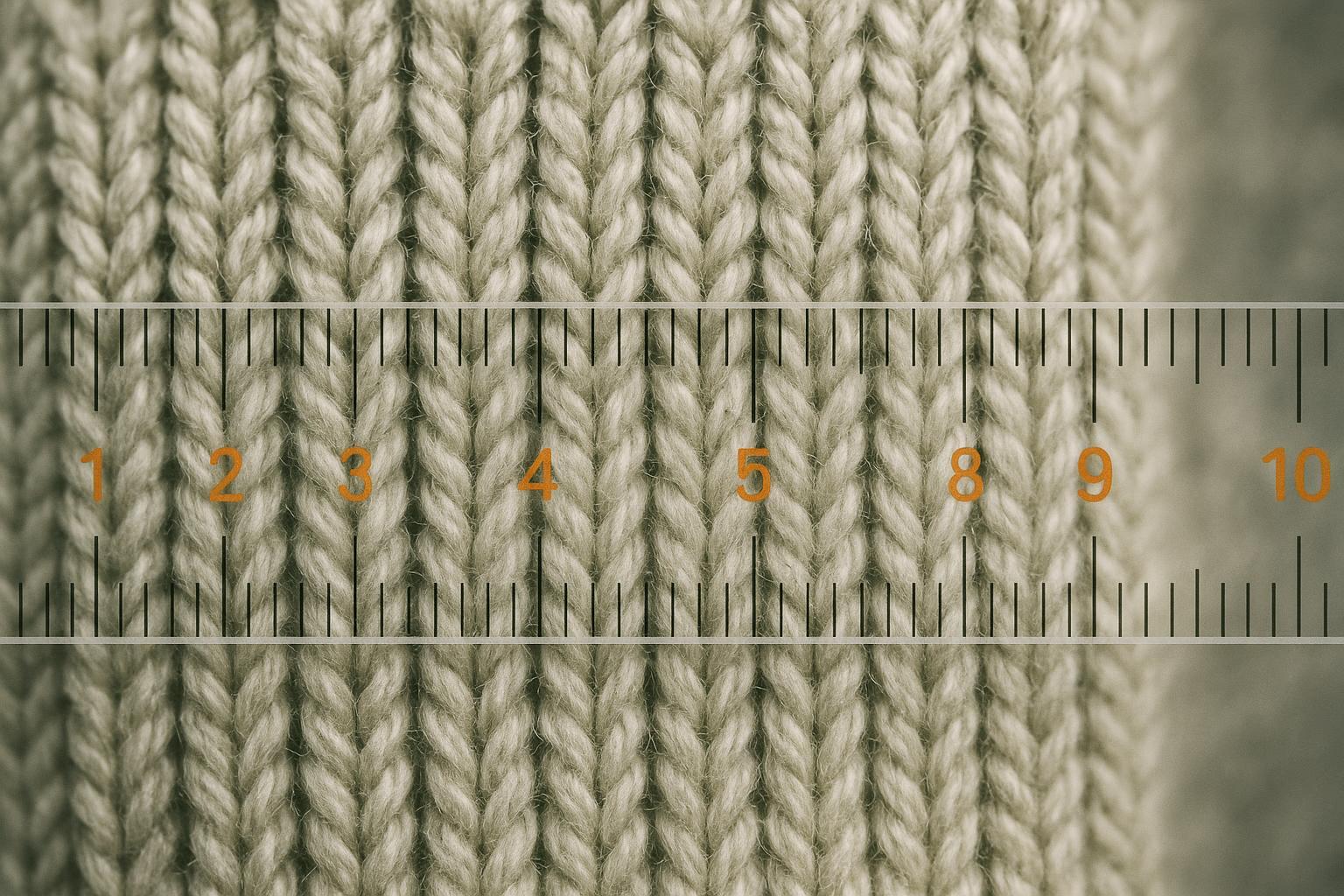

We model a petite cloud sweater in fine gauge with a target of ~17 stitches per 10 cm. We count V‑stitches across a marked 10 cm span to verify density and drape.

We map a milestone timeline from T0 brief to T+72–120h sample ship notice, logging response times at each step.

We run home‑laundering stabilization and evaluate shrinkage via AATCC TM135 guidance, alongside colorfastness expectations per AATCC TM61 and TM8/116. Where WHOLEGARMENT is used, we inspect shoulder and underarm areas for seamless integrity.

For production realism at low MOQs (50–100 pcs), we note common cost drivers (yarn, stitch complexity, finishing, labels, tests) and compare quotes vs invoices for variance.

Note: This review follows a standardized protocol. Where artifacts aren’t publicly posted, we indicate “Insufficient data” and invite buyers to request the PDFs/logs.

Results and analysis

Sampling speed and SLA conditions

A fast cycle is achievable when prerequisites are clear and yarns are available. According to the official page on 3–5 day sampling, stock‑service yarns and concise tech packs enable the shortest lead times. Complex yarns (e.g., cashmere) can extend to 5–7 days. For petite cloud sweaters, choosing an in‑stock soft‑hand blend often keeps the cycle inside the 3–5‑day window. Learn more on Xindi’s Quick Sampling resource.

Internal references: the Quick Sampling page explains the 3–5 day window; low‑MOQ feasibility is detailed on the Low MOQ Production page.

Fine‑gauge control at ~17 sts/10 cm

To verify density, we place a transparent ruler over the fabric and count the V‑stitches across an exact 10 cm span. Around 17 stitches per 10 cm typically delivers a light, smooth drape ideal for petite cloud aesthetics. Stitch density also interacts with yarn loft; loftier blends (merino/alpaca/cashmere) need careful tensioning to avoid biasing or torque.

WHOLEGARMENT note: When executed on suitable machines, seamless construction removes side seams and armhole linking, improving comfort and reducing bulk. Shima Seiki’s MACH2 series documents density control systems that help maintain consistency across panels and zones.

WHOLEGARMENT construction feasibility

Seamless output depends on scheduling access to WholeGarment‑capable machines and on the garment’s shape and yarn. For petite cloud sweaters, seamless shoulders and underarms deliver the most noticeable comfort gains. If WHOLEGARMENT scheduling isn’t available for a prototype slot, a panel‑knit alternative can be used for fit validation, with seamless construction reserved for the pre‑production sample. For a technical overview of seamless capabilities and density control, see Shima Seiki’s MACH2 family brochures.

Wash, pilling, and colorfastness expectations

For petite cloud sweaters, stabilize via home laundering and blocking before measuring final POMs. AATCC TM135 and ISO 6330 methods underpin dimensional‑change targets (≤3–6% is a practical acceptance band for most blends). For surface durability, target pilling grade ≥3 (≥4 is good) and colorfastness to laundering ≥4; crocking targets: dry ≥4, wet ≥3. These thresholds are standard‑aligned expectations; buyers should request the specific lab reports for the chosen yarn and knit structure. For method references, consult the AATCC standards overview.

Who it’s for — and who it isn’t

Best fit: Independent brands and designers who need petite cloud sweaters at low MOQ with fast, verifiable sampling. Teams that can supply clear tech packs, agree on stock‑service yarns for speed, and accept a methodical testing protocol.

Not ideal: Projects requiring exotic yarns on rush timelines, demanding public certificate IDs on the website (rather than in a private bundle), or expecting published price lists. Those scenarios either extend timelines or require pre‑engagement document exchange.

Competitors compared (as of Feb 2026)

Vendor | Sampling speed | MOQ stance | WHOLEGARMENT/fine gauge | Certifications visibility | Pricing visibility |

|---|---|---|---|---|---|

Xindi Knitwear | 3–5 days typical; 5–7 for complex fibers. | 50–100 pcs typical. | Seamless feasible; fine‑gauge control targeted at ~17 sts/10 cm. | Certificates available on request; not public on site. | Custom quotes only. |

Tailored Industry (USA) | On‑demand, rapid; exact SLA varies by integration. | Zero MOQ on‑demand; higher for bulk. | Strong 3D/WholeGarment positioning (US). | No formal certificate IDs on reviewed pages. | Service‑tier pricing pages; per‑unit not public. |

DGJIAYAN (China) | Samples 4–8 weeks; production 60–120 days reported. | Often 100–200 pcs. | Broad gauge range; not focused on seamless. | Generic compliance mentions; details unclear. | Custom quotes only. |

Note: We normalize criteria for fairness and mark where public evidence is limited.

Costs and MOQs at a glance

Typical MOQs: 50–100 pcs per style/color, subject to yarn availability and dyeing constraints. Small runs carry higher unit costs due to setup and yarn loss. Consult Xindi’s Low MOQ Production guidance for context on how quantities interact with yarn and finishing.

Cost drivers: yarn composition and grade (cashmere vs merino/alpaca blends), stitch complexity and density, number of colorways, trims/labels/packaging, lab testing, and logistics.

Practical tip: Lock stock‑service yarns early and keep colorways tight to preserve cost predictability.

Communication cadence and milestones

A predictable cadence reduces rework and season‑window risk. The following timeline has worked well for cross‑timezone teams and aligns with our testing protocol methodology. Xindi’s OEM/ODM process page offers additional context on how development hands off to production.

T0: Design brief and tech pack shared; confirm target density (~17 sts/10 cm) and size run.

T+24h: Technical confirmation (yarn stock, gauge plan, WHOLEGARMENT scheduling) and risk notes.

T+72–120h: Sample completion and ship notice; photos of stitch density and interior construction shared.

T+7d: Feedback and revision slot (if required); finalize for small‑batch production (50–100 pcs).

Maintain an average response time measured in hours, not days, and keep a shared tracker for decisions and risks.

Certifications — what to request and how to verify

If your project requires certified inputs, ask for the certificate bundle with validity dates and scope statements. Verify chemical safety claims against OEKO‑TEX Standard 100 guidance, confirm organic and recycled chains through the GOTS official site (supplier database) and the Textile Exchange systems, and validate wool provenance via the Responsible Wool Standard documentation. Xindi shares certificate PDFs on request; we recommend matching certificate scopes to specific yarn lots and colorways during PO confirmation.

Limitations and risks to consider

Certificate IDs/PDFs for OEKO‑TEX/GOTS/GRS/RWS aren’t listed publicly on the site; request the bundle to verify chain of custody.

There’s no public page listing machine models or a WHOLEGARMENT gallery; ask for a current machine list and sample photos during scoping.

Pricing is custom and varies by yarn and complexity; we don’t publish per‑unit tables. Quotes are the only reliable way to assess margin.

Sources and definitions (selected)

WHOLEGARMENT machinery and density control are documented by Shima Seiki in the MACH2 family brochures.

Quality thresholds reference the AATCC standards overview (TM135, TM61, TM8/116) and ISO/ASTM methods (ISO 6330; ASTM D3786) that underpin knit testing.

Certification frameworks are defined by OEKO‑TEX Standard 100, the GOTS official site, and the Responsible Wool Standard; use their registries to validate.

Closing verdict

If your next drop requires petite cloud sweaters at low MOQ with fast, verifiable sampling and fine‑gauge consistency, Xindi stands out for speed, stitch‑density control around ~17 sts/10 cm, and practical WHOLEGARMENT execution when scheduled. The trade‑offs are predictable for small‑run OEM work: certification PDFs are shared on request, machine lists aren’t public, and pricing is quote‑based. For many early‑stage brands, that balance still hits the sweet spot—quick validation, reliable fit, and a clean path to a 50–100‑piece release.

Ready to move from concept to a first‑pass prototype? Request a 3–5 day sampling slot or a small‑order quote on Xindi’s official site.

Quick Sampling | Low MOQ Production | OEM/ODM process

External references: Shima Seiki MACH2 brochure | AATCC standards overview | OEKO‑TEX Standard 100 | GOTS official site | Responsible Wool Standard