If you’re planning an alpaca knitwear drop for Pre-Fall, the calendar is your biggest constraint. This guide gives you a factory-grade critical path—counting back from the DC receiving window (July 15–August 1, 2026)—with a realistic 3–5 day sampling flow, holiday buffers, QC/AQL gates, and clear air vs ocean trade-offs. Think of it as a working playbook you can tailor for 100% Baby Alpaca or alpaca blends.

Key takeaways

Anchor everything to the DC booking date, then count back through customs, transit, export cut-offs, QC, bulk, sample sign-off, and tech pack freeze.

A practical alpaca sweater sampling timeline is 3–5 days for standard styles; complex stitches or programming can push to 5–7.

Add buffers for China’s 2026 holidays: Spring Festival (+4–6 weeks), Mid‑Autumn (+2 weeks), Golden Week (+3 weeks), and bake in AQL gates.

Use air for first-drop “seed” inventory to hit 7/15–8/01; replenish by ocean for margin stability.

Document accept/reject criteria (shrinkage, pilling, color) during sample sign‑off to prevent rework later.

What “3–5 day sampling” really covers for alpaca

“3–5 days” assumes you have a clean tech pack, yarn-in-hand (or swappable proxy), and an executable stitch plan. In practice:

Baby Alpaca: softer hand, potential for higher pilling without the right twist/density. Plan lab tests early and confirm wash/finish.

WHOLEGARMENT basics: seamless construction removes linking time but may need first-lot needle audits and tighter programming control on gauges like 7G–12G.

Complex jacquards, heavy cables, or intarsia: expect 5–7 days.

For background on cadence and workflow, see the quick sampling overview in the internal resource on 3–7 day sampling and day‑by‑day handoff in the production room: the team’s guide to quick sampling. If you’re deciding density and hand-feel, review sweater gauge types. We’ll reference the OEM/ODM staging later as well via the knitwear production process.

You’ll see the phrase alpaca sweater sampling timeline throughout this guide—it’s the anchor for sequencing approvals, tests, and logistics.

The anchor: Pre‑Fall DC receiving window (7/15–8/01) and how to count back

We’ll use a concrete date inside that window to demonstrate countback. Pick your DC appointment, then work upstream to set each milestone and buffer. For example, let’s anchor to Monday, July 20, 2026 (inside 7/15–8/01). If your DC requires 3–5 business days’ notice and ASN compliance, you’ll want your freight on hand locally by July 15–17 at the latest.

Air and ocean windows differ dramatically. Typical door-to-door windows, supported by logistics sources, look like this:

Air, South China → US West: 5–9 days; East/Gulf: 7–14 including clearance and inland, according to the shipping trend guidance from Shapiro (2026) and corroborating primers by Gerudo Logistics.

Ocean, South China → US West: roughly 20–35 days door-to-door; US East: 30–50 days depending on route and inland. Peak seasons add days; gate-in typically 5–7 days pre‑ETD, per industry practice and Maersk’s peak‑period advisories (2025/2026).

Holiday overlays (China 2026) matter: Spring Festival Feb 15–23 (+4–6 weeks), Mid‑Autumn Sep 25–27 (+2 weeks), Golden Week Oct 1–7 (+3 weeks), per the State Council’s holiday arrangement (2025 update, for 2026) with supplementary date context from TravelChinaGuide.

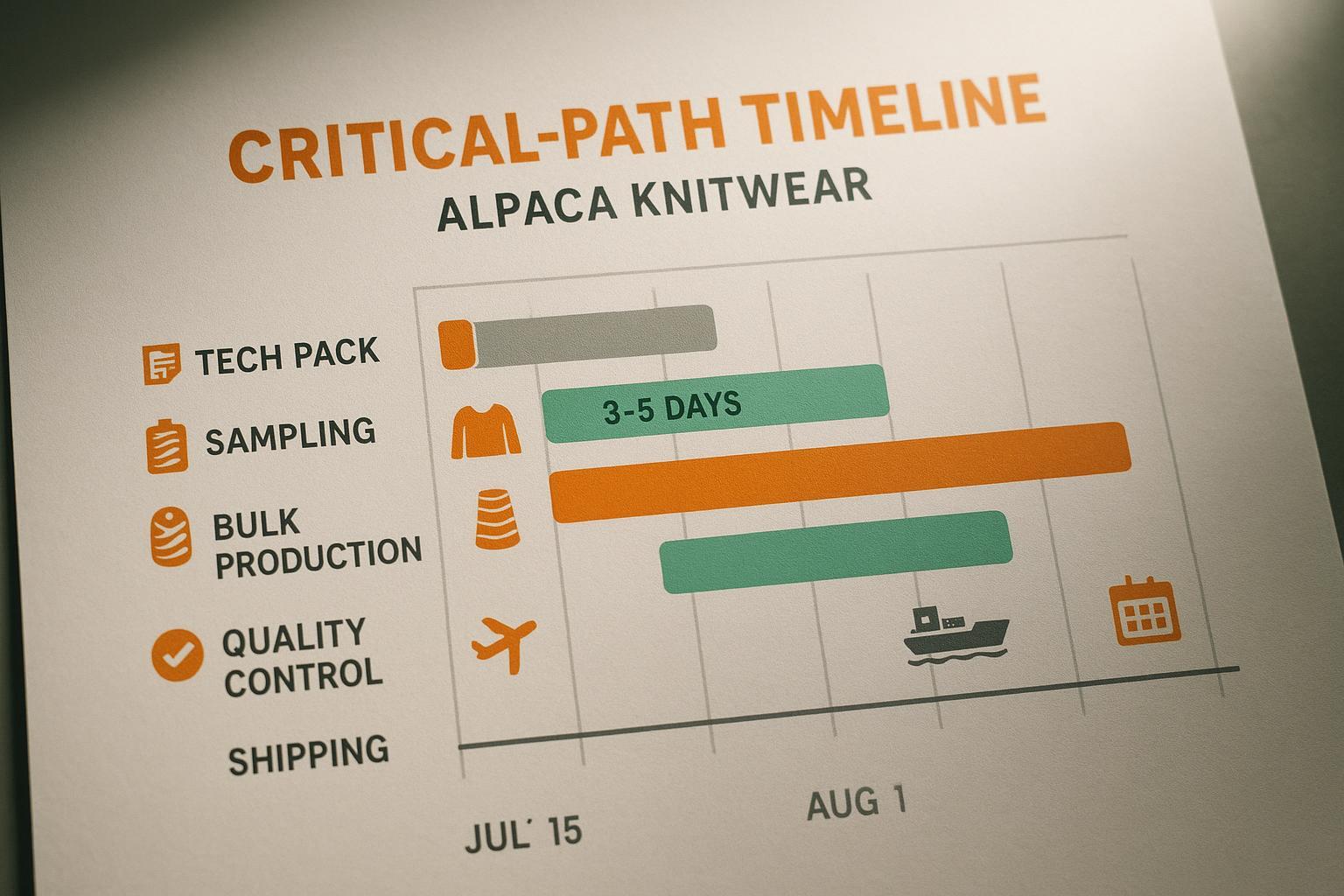

Critical‑path Gantt for your alpaca sweater sampling timeline (counting back from a 2026-07-20 DC receipt)

Legend: [■ Planned] [□ Buffer] — durations are typical working days (wd) unless noted

Anchor: DC Receipt Mon 2026-07-20 (Pre-Fall window 7/15–8/01)

DC Booking & ASN ■■■ 07/15–07/19 (book 3–5 biz days prior)

US Customs & Inland ■■□ Air: 1–3d; Ocean: 3–10d → Target arrival 07/10–07/17

International Transit ■■■□ Air D2D 5–10d → Ex-factory 07/01–07/08

■■■■■■■□ Ocean D2D 20–35d (West) / 30–50d (East) → Gate-in 06/05–06/20 (WC) or 05/25–06/10 (EC)

Export Docs & Cut‑offs ■■□ 5–10d before ETD (ISF for ocean, book uplift/sailing)

Final QC/AQL & Packing ■■■ 3–5d (AQL 0/2.5/4.0; WHOLEGARMENT first-lot needle audit)

Bulk Production ■■■■■■■■ 15–30d (knit → wash/block → measure → finish/brand)

Materials & Lab Tests ■■□ 5–10d (lab dips; pilling, shrinkage, colorfastness)

PO Issue & Capacity Hold ■■ 1–3d (machines, wash house, inspection slots)

Sample Approval & Size Set ■■■ 3–7d (fit, shrinkage, color sign-off)

Sampling (Tech→Proto) ■■■ 3–5d typical (5–7d complex stitches)

Tech Pack Freeze ■■■■■ Set −60 to −90 days from DC → by late Apr to mid‑May

Holiday overlays (avoid gates ± buffers):

- Spring Festival 02/15–02/23 +4–6 weeks

- Mid‑Autumn 09/25–09/27 +2 weeks (after your Pre‑Fall, still relevant for replenishment)

- Golden Week 10/01–10/07 +3 weeks (replenishment planning)

This diagram embeds your alpaca sweater sampling timeline into the broader chain so you can lock approvals before you commit bulk and bookings.

Step‑by‑step walkthrough of each milestone

1) Tech pack freeze (late April to mid‑May)

Deliverables: full measurement table with tolerances, stitch charts, gauge, yarn spec (Nm, twist, fiber content), trims and branding, care labels per US/EU rules, and packaging specs. For stitch and yarn references, see the internal primers on yarn types and stitch types.

Verification: include shrinkage accept thresholds (≤3% length/width after wash), color ΔE limit between lab dip and bulk, and any hand‑feel notes relevant to Baby Alpaca.

2) Sampling (3–5 days; 5–7 if complex)

Kick off once the tech pack is frozen and yarn is available. Request photo/video of knitting and post‑wash prototype on Day 2–3. If you’re using WHOLEGARMENT, make sure programming notes, density, and finish are captured for reproducibility. A short, well‑documented alpaca sweater sampling timeline here pays off downstream.

3) Sample approval and size set (3–7 days)

Approve fit, shrinkage, and color. Sign off with explicit accept/reject criteria in a simple form. Keep your tolerance table attached to the email thread. Document any deviations and their cost/time impact.

Testing pointers for alpaca:

Pilling: ISO 12945‑2 target ≥ grade 3.

Dimensional stability after wash: ISO 6330 or AATCC TM 135; target ≤3%.

Colorfastness: AATCC TM 61 (laundering) and AATCC TM 8 (crocking). See the standards overviews at AATCC and the ISO OBP index for ISO 12945‑2/ISO 6330.

4) PO issue and capacity booking (1–3 days)

Book machine time, wash house capacity, and inspection. Align tentative ETD/ETA windows with your freight forwarder now.

5) Materials, lab dips, and lab tests (5–10 days)

Lock lab dips. For 100% Baby Alpaca, verify fiber content and consider third‑party tests. For US labeling and fiber disclosure under the Wool Products Labeling Act, see the FTC’s guidance on clothing and textiles labeling.

6) Bulk production (15–30 days)

Sequence: knit → link or seamless → wash/block → measure/tolerance → finishing and branding. For process clarity, review the internal overview of the OEM/ODM knitwear production process and a primer on finishing & assembly. WHOLEGARMENT can save linking time but budget extra for first‑lot programming and needle audits.

7) Final QC/AQL, packing & export prep (3–5 days, overlaps docs)

Inspection plan: AQL Critical 0 / Major 2.5 / Minor 4.0 using ISO 2859‑1 (GII). First WHOLEGARMENT lot: 100% needle audit. References: QIMA’s AQL overview and AQIService’s AQL 2.5 explainer.

Export docs: commercial invoice, packing list, HS codes, COO; for ocean shipments, ensure timely ISF filing and book gate‑in 5–7 days pre‑ETD.

8) International transit, customs, and DC booking

Air: plan 5–10 days door‑to‑door (West 5–9; East/Gulf 7–14). Ocean: 20–35 days West, 30–50 days East door‑to‑door, plus peak buffers. Book DC appointments 3–5 business days ahead, confirm ASN and carton label compliance, and allow customs/inland variability.

Air vs ocean trade‑offs and mixed strategies

Transit and planning ranges (conservative, source‑based):

Mode/Route | Typical door‑to‑door | Planning notes |

|---|---|---|

Air, South China → US West | 5–9 days | Faster DC hit; higher unit freight cost |

Air, South China → US East/Gulf | 7–14 days | Add 1–3 days for inland legs |

Ocean, South China → US West | 20–35 days | Gate‑in 5–7 days pre‑ETD; add peak buffers |

Ocean, South China → US East | 30–50 days | Longer door‑to‑door; watch port/canal risks |

Decision matrix (useful when your calendar is tight but margins matter):

Situation | Recommendation | Rationale |

|---|---|---|

First drop must hit 7/15–8/01 | First batch by air | Secure sell‑through; avoid missing shelf window |

Replenishment after early sell‑through | Ocean | Stabilize margin; plan countback early |

Mixed demand across colors/sizes | ABC split (A by air; B/C by sea) | Allocate freight budget where it pays back |

Emergency delay in bulk or QC | Air rescue threshold per unit | Cap max $/unit uplift to protect margin |

Here’s the deal: the alpaca sweater sampling timeline is only useful if logistics choices line up with your DC appointment. If you don’t pre‑book capacity, you’ll spend your buffer before the goods even leave the factory.

Practical workflow example (neutral, disclosed reference)

Disclosure: Xindi Knitwear is our product. In practice, we use neutral factory windows similar to what Xindi publishes publicly (e.g., 3–7 day sampling, 15–30 day bulk) and verify logistics ranges against forwarder guidance.

Scenario: 100% Baby Alpaca crewneck, WHOLEGARMENT basic, DC appointment Monday 2026‑07‑20.

Target arrival at US gateway by 07/15–07/17; DC booking made 3–5 business days prior with ASN.

Choose “first batch air; replenishment by sea.”

Countback:

Air door‑to‑door 7–10 days in July → ex‑factory 07/05–07/08.

Final QC/AQL + export docs 06/30–07/04.

Bulk (conservative 20 days) 06/10–06/29.

Lab dips + tests 06/03–06/09.

PO & capacity booking 05/31–06/02.

Sample approval/size set 05/24–05/30.

Sampling 05/19–05/23 (3–5 days).

Tech pack freeze by 05/10.

Holiday check: Spring Festival buffers are behind you, but if a replenishment by sea touches September/October, add +2 weeks (Mid‑Autumn) or +3 weeks (Golden Week) to production or export planning per the State Council holiday schedule.

QC/Compliance: Pre‑shipment AQL 0/2.5/4.0 (GII). For labeling and fiber disclosure (alpaca as specialty wool), follow the FTC’s clothing and textiles rules.

Holiday buffers you should bake in (2026)

Holiday (China) | 2026 Dates | Recommended buffer |

|---|---|---|

Spring Festival | Feb 15–23 | +4–6 weeks |

Mid‑Autumn | Sep 25–27 | +2 weeks |

Golden Week | Oct 1–7 | +3 weeks |

These reflect factory shutdowns and logistics slowdowns commonly observed; verify with your vendors and forwarders. See Maersk’s peak‑period guidance for seasonal impacts.

Troubleshooting and contingencies (alpaca‑specific)

Excess shrinkage (>3%): adjust wash recipe, rebalance knitting tension, and re‑block; confirm care label instructions match the verified method. If the defect appears after color changes, re‑test that colorway.

Pilling below grade: move to a tighter twist, consider an alpaca‑blend option with improved abrasion, apply an anti‑pilling finish, or slightly increase density/gauge.

Color lot mismatch: enforce lab‑dip approvals, record ΔE thresholds in the tech pack, and segregate yarn lots during bulk.

Missed cut‑offs: pre‑book sailings/uplift; split shipments; set an emergency per‑unit air uplift ceiling to protect margin.

WHOLEGARMENT first‑lot artifacts: conduct a 100% needle audit; recalibrate cams; run a slightly larger pilot to confirm stability before full bulk.

Think of it this way: every hour you invest in sample sign‑off clarity saves days when you’re staring at a DC window that won’t move.

FAQ

Q1: How many samples do I need before locking bulk?

A: For Baby Alpaca basics, 1 proto + 1 revised proto + size set is typical. If you change yarn lot or color chemistry, re‑test shrinkage and pilling.

Q2: Can the alpaca sweater sampling timeline truly hit 3–5 days in peak season?

A: Yes, with yarn-in-hand and a frozen tech pack. In peak periods, pre‑book sampling slots and expect 1–2 extra days for courier or programming if complexity rises.

Q3: What AQL should I use?

A: Critical 0 / Major 2.5 / Minor 4.0 (ISO 2859‑1, GII) is widely adopted in apparel and is a solid starting point for Pre‑Fall drops.

Q4: What about labeling and US compliance?

A: Follow the FTC’s Clothing & Textiles guidance (Wool Products Labeling Act), include fiber percentages (alpaca as specialty wool), COO, and responsible party.

Next steps

If you need a sanity check on your calendar, copy this countback into your own plan, add your forwarder’s live schedules, and pressure‑test every buffer. For deeper dives into sampling cadence and operations, see the internal explainers on quick sampling and gauge types. If you want a neutral review of your Pre‑Fall critical path or to align factory windows with your ASN/DC rules, a partner like Xindi Knitwear can support timeline mapping without changing your design intent.

Notes on sources cited in this guide: air timing norms are summarized from Shapiro’s China→US trends and Gerudo Logistics primers; seasonal/peak effects from Maersk’s 2026 peak‑period guidance; China holiday dates from the State Council’s 2026 arrangement; AQL practice via QIMA and AQIService; textile testing and labeling references via AATCC, ISO OBP, and the FTC.