You want products with no defects every time you order. AQL 2.5 explained helps you reach this goal. When you pick aql 2.5, you set a strict rule for quality in your shipments. AQL 2.5 explained means you let fewer defects in each group, which keeps customers happy and makes products better. Check the table below to see how aql 2.5 explained is different from higher aql levels:

AQL Level | Tolerance for Defects | Impact on Defect Rates |

|---|---|---|

2.5 | Stricter tolerance | Fewer defects accepted |

Higher | More defects allowed | Higher defect rates |

AQL 2.5 explained lowers the chance of sending bad products to customers. You use aql 2.5 explained when you check products to make sure they are good quality. AQL 2.5 explained helps you feel sure your product will make every customer happy.

Key Takeaways

AQL 2.5 has strict rules for defects, so products are better and customers are happier.

Knowing the difference between critical, major, and minor defects helps keep the brand’s good name and makes sure products work well.

AQL sampling checks only some products, which saves time and money but still keeps quality high.

Training inspection teams often helps them find more defects and makes products better.

Having a strong quality control process from start to finish makes sure shipments have no defects.

What is AQL (Acceptable Quality Limit)?

You need a simple way to check your product before customers get it. AQL helps you do this. It stands for acceptable quality limit. ISO 2859-1 says the acceptable quality limit is the worst quality you will allow. This means you decide how many defects are okay in a batch. If there are too many, you reject it. When you use AQL 2.5, you pick a strict rule for your product. This helps keep your customers happy and your product good.

How Do We Read the ISO 2859-1 Sampling Tables?

AQL sampling uses special tables to help you check products. These tables tell you how many items to look at and how many defects you can accept. Here are the steps you follow:

Find your lot size and choose the inspection level in Table 1.

Look for the sample size code letter in Table 2.

Use the code letter to confirm your sample size.

Set your acceptance and rejection points for critical, major, and minor defects.

Figure out the most defects you can allow for your chosen quality level.

Understanding Lot Size vs. Sample Size

Lot size is the total number of products in your shipment. Sample size is how many you check during AQL sampling. For example, if your lot size is 5,000, you might only check 200 pieces. This saves time and money but still keeps your customer safe.

How Do We Determine the Correct Sample Size?

You pick your sample size by looking at a few things:

Lot size

Inspection levels (I, II, III)

Production conditions

Type of inspection (normal, reduced, or tightened)

AQL sampling uses these things to make sure your checks are fair and work well.

General Inspection Levels (I, II, III)

There are three general inspection levels in AQL sampling:

Level I: Smallest sample size, good for low risk or small budgets.

Level II: Normal sample size, used most often for AQL testing.

Level III: Biggest sample size, best for strict quality needs.

If you have 5,000 products, Level I might check 80 pieces, Level II checks 200, and Level III checks 315. You pick the level that fits your customer and your product’s risk.

AQL sampling helps you protect your customer and your business. You use AQL 2.5 to set a strong quality rule. This keeps your product good and your customer happy.

How Are Defects Categorized in Knitwear?

You need to know about defect categories to keep knitwear quality high. When you put bad products into groups, you protect your brand. This also helps your customer get only the best items. Sorting defects is very important for export shipments because:

Finding and removing bad products makes your brand look better.

Fewer mistakes in making products means happier customers.

What Constitutes a Critical Defect?

Critical defects are the worst problems in knitwear. These break safety rules or laws. If you find even one critical defect, you must reject the whole batch. Some examples are sharp things, broken needles, or dangerous chemicals in the clothes.

Safety Issues and Hazardous Materials

You must always check for safety problems and dangerous materials. Rules say critical defects include:

Sharp metal pieces in the product.

Poisonous chemicals that go over the legal limit.

Choking risks in baby clothes that are not marked.

Other common critical defects in knitwear are:

Shade changes

Dirt or stains

Uneven color or dye marks

Dropped stitches

Wrong or missing printing

Crease marks

Knots or bumps

Holes

Needle lines

Broken threads

If you see any of these, you must treat the product as a big risk.

What is the Difference Between Major and Minor Defects?

You need to know the difference between major and minor defects to make good choices during checks. Major defects are big problems. They make the product unsellable or cause returns. Minor defects are small problems. They do not stop the product from working, but they can hurt your brand’s image.

Major defects are easy to see and often cause complaints or returns.

Minor defects are small and do not change how the product works.

Functional Failures vs. Visual Imperfections

You can split major and minor defects into two types:

Functional failures: These are broken seams, zippers that do not work, or weak parts. They stop the product from working right.

Visual imperfections: These are small stains, little color changes, or tiny stitching problems. They do not stop the product from working, but they make it look worse.

Here is a table to show how each defect type affects the customer:

Defect Type | Impact on Customer Satisfaction and Usability | Examples |

|---|---|---|

Major Defects | Make customers less happy, hurt how it works, and may cause returns or complaints. | Functional failures, weak parts, wrong labels |

Minor Defects | Make the product look worse, may not change use, but can hurt your brand’s image. | Small scratches, tiny stitching, little color changes |

What is the Passing Criteria for AQL 2.5?

AQL 2.5 sets strict rules for how many bad products you can have in each batch. You use this rule to decide if your shipment passes or fails. If you find more bad products than allowed, you must reject the batch.

Maximum Allowed Defects per Batch

AQL 2.5 means you can only have a few bad products in your shipment. Here is a table that shows the most defects you can have in a normal check:

Defect Type | Maximum Allowed Defects |

|---|---|

Critical Defects | 0 |

Major Defects | 2.5 |

Minor Defects | 4 |

For example, if your lot size is 550 and you check 32 pieces, you can accept up to 2 bad products. If you find 3 or more, you must reject the batch.

Lot Size | Sample Size | Acceptable Defects | Result |

|---|---|---|---|

550 | 32 | 2 or less | Accepted |

550 | 32 | 3 or more | Rejected |

AQL 2.5 helps you keep bad products out of your shipments. You use this rule to make sure your customer gets a product that meets high standards. By following these defect groups and limits, you protect your brand and keep your customer happy.

What Does Our Quality Control Process Look Like?

You want every product to be high quality before customers get it. To do this, you need a strong plan that checks every step. This starts with raw materials and ends with the final shipment. Here is how our process works:

Why is Pre-Production Inspection (PPI) Crucial?

Pre-production inspection is the first step to stop big problems. You check raw materials and colors before making anything. This helps you find issues early. Early checks keep your products good and save time and money.

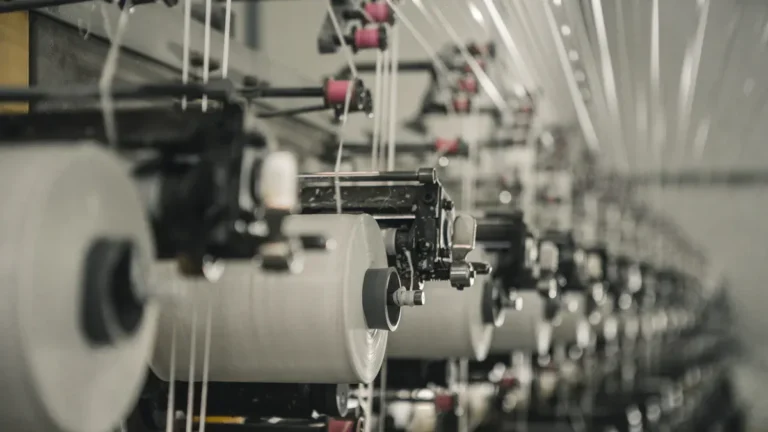

Verifying Yarn Lots and Color Consistency

You begin by checking yarn lots and dye batches. You match each yarn lot number and color to approved samples. The Four-Point Inspection System helps grade fabric and find big problems early. Regular checks and quick defect spotting keep product quality steady.

Tip: Teach your team to spot problems early. This makes your quality control better.

What Happens During Inline Inspection (DPI)?

Inline inspection happens while products are being made. You watch the knitting process and look for mistakes right away. This helps you fix problems before they get worse.

Catching Knitting Faults Early

You look for dropped stitches, holes, and tension issues. Inspectors check finished and partly finished items. They also watch how workers do their jobs and check the factory. Early warnings and fast feedback help you fix problems quickly.

Monitoring Size Specs During Ironing

After ironing, you measure each piece to check the size. Ironing can change the shape and size of knitwear. Accurate measuring helps you meet customer needs and quality rules.

How is the Final Random Inspection (FRI) Conducted?

Final random inspection happens when most of the shipment is packed. You pick samples randomly and check them using aql inspection standards. You look for stains, mold, color problems, and correct labels. You also check if products follow customer and international rules.

Packaging, Hand-Feel, and Final Aesthetics

You check packaging for folding, labels, and barcodes. You feel the garment after washing to make sure it is comfortable. You also look for stains, holes, or pressing marks. These checks make sure your customer gets a product that meets all quality and shipping rules.

Step | Description |

|---|---|

Checks suppliers, fabric, trims, samples, and patterns to stop problems before making starts. | |

In-Line Quality Control | Includes checks during making, worker audits, process watching, and training to keep quality high. |

Post Production Quality Inspection | Has final checks, packaging review, shipment approval, and paperwork to make sure products are good before shipping. |

By following these steps, you use aql and aql inspection to keep your products high quality and give your customer the best results.

What Common Knitwear Defects Do We Filter Out?

You want every product to be good and make customers happy. During checks, you look for the most common knitwear defects. These problems can change how customers feel about your product. Some examples are:

Barre (streaks in fabric)

Drop stitches

Holes

Needle lines

Birdseye or tucking defects

Broken filaments or yarn

Skewing or spirality

Open seams

Shade variation

Dirt or stains

How Do We Spot Knitting Faults?

You use your eyes and hands to find knitting faults. You look for holes, broken threads, and odd spots in the fabric. You also touch the fabric to feel for bumps or loose stitches. This helps you find problems early and keep products good.

Stage of Production | |

|---|---|

Fabric Manufacturing | Holes, broken threads, slubs, snags, irregularities |

Dyeing and Printing | Color variations, streaks, smudges, misprints |

Cutting and Sewing | Uneven edges, mismatched patterns, incorrect measurements |

Finished Product Inspection | Loose threads, missing buttons, zippers, manufacturing defects |

What Causes Dropped Stitches and Holes?

Dropped stitches and holes happen when machines or yarn have problems. Dropped stitches can come from a bad needle or wrong yarn feeder. Yarn tension that is too low can also cause this. Holes may show up if the yarn breaks or the material is too dry. Machine settings that are not right can also cause holes. You teach your team to spot these fast to keep quality high.

How Do We Detect Barre Marks and Needle Lines?

You look for barre marks and needle lines under bright lights. You move the fabric around to see lines or streaks. These marks can come from yarn size changes or machine problems. You take out any product with these marks to keep customers happy.

What Finishing Defects Are Unacceptable?

You make clear rules for finishing defects. You do not allow bad seam lines, twisted garments, or uneven shapes. These problems make products look bad and upset customers.

Identifying Poor Seam Alignment and Skewing

You measure seams to see if they match up. Skewing happens when fabric twists from wrong tension during knitting. You use tables to check seam spots and shapes. If you see twisted seams or odd shapes, you do not accept the product.

Ensuring Measurements Meet the Tolerance (+/-)

You use special measuring tapes and rulers to check each item. You lay clothes flat and measure places like chest and sleeve length. You check sizes again to make sure they are within the allowed range. This helps you give the right fit and keep customers happy.

Tip: Training your inspection team often helps them find more defects and make products better.

You want every product to reach your customer in perfect condition. Using aql 2.5 in your inspection process brings real improvement to your shipments. You see improvement in product quality, fewer returns, and more defect-free products. With aql, you:

lower the risk of sending bad product to your customer

meet world standards for product quality

save money by not checking every single product

Aql helps you set clear rules for each defect type. You must remember that aql does not always guarantee defect-free products. Sometimes, the sample size or unclear limits can let hidden defects pass. For the best improvement, always define what counts as a defect and train your team to spot problems. This way, you give your customer the best product every time.

FAQ

What does aql mean for your product quality?

Aql sets the limit for defects in your product batch. You use aql to decide if your product meets your quality goals. This helps you deliver better results to your customer.

How does aql 2.5 protect your customer?

Aql 2.5 uses strict rules to lower the number of defects in each product shipment. Your customer receives safer and more reliable products. You build trust with every order.

Why do you inspect only samples and not every product?

You save time and money by checking samples instead of every product. Aql sampling lets you find problems before your customer gets the product. You still keep high standards.

What happens if your product fails the aql inspection?

If your product fails the aql inspection, you must fix the defects before shipping. Your customer will not get poor-quality products. You keep your reputation strong.