You love great knitwear. Maybe you dream about launching your own designs or growing your brand. Finding the right california knitwear manufacturer can feel tricky. You want quality, speed, and someone who understands your vision. It helps to know what matters most to you and your customers. Are you ready to see your ideas come to life? Let’s dive in and explore what makes the process exciting.

Key Takeaways

Figure out what your brand needs before you look for a manufacturer. Know your level, your niche, and what products you want.

Think about how hard your designs are to make. Pick a manufacturer who can make the styles you want.

Look at the materials you want to use. Make sure the manufacturer can use your favorite fabrics. This is important if you want eco-friendly choices.

Quality and cost are very important. Decide what is most important for your brand. Find a manufacturer who can give you what you need.

Learn about different manufacturers. Full-service factories do many things. Small-batch studios give more personal help.

Look for certifications and quality standards. This helps you know the manufacturer is safe and follows good rules.

Try to visit the manufacturers if you can. Seeing their work in person helps you know if they are good.

Make a good relationship with your manufacturer. Talking and working together helps you get better products and easier production.

Identify Your Brand Needs

Before you look for a manufacturer, think about your brand. Every brand has its own story and style. When you know what your brand is about, you can find a manufacturer that matches. Let’s talk about what you should consider.

Brand Level

Startup vs. Established

Is your brand new, or has it been around? Startups may want small orders and extra help. Established brands might need bigger orders and fast service. Your brand’s stage changes what you need from a manufacturer.

Niche vs. Mass Market

Does your brand serve a special group, or many people? Niche brands often want unique designs or special requests. Mass market brands may need lots of products quickly. Think about who you want to reach before you choose.

Product Requirements

Your products make your brand different. You need a manufacturer who can make your ideas real.

Design Complexity

Some brands like bold patterns or special shapes. If your designs are tricky, you need a manufacturer who can do them. Not all manufacturers have the right skills or machines. Ask for samples that match your brand’s look.

Materials

The materials you pick show what your brand stands for. Do you want soft cotton, recycled yarn, or luxury blends? Some manufacturers work with certain materials. If you care about eco-friendly choices, find a manufacturer who offers them.

Here’s a quick look at how product needs can change your choice:

Factor | Impact on Manufacturer Selection |

|---|---|

Specialization | Some manufacturers focus on certain products or materials, which may fit your brand’s needs. |

Design Complexity | Brands with complex designs need a manufacturer who can handle detailed work. |

Material Choice | Your brand’s material choices can limit or expand your manufacturer options. |

Quality Control | Good quality control keeps your brand’s reputation strong. |

Sustainability | Brands that value the planet should pick a manufacturer with eco-friendly practices. |

Key Priorities

Every brand cares about different things. You need to choose what matters most.

Quality vs. Cost

Some brands want top quality. Others need to save money. If you want luxury, you may pay more. If you need lower prices, look for a manufacturer who offers them. Make a list of what is most important to your brand.

Sustainability

Many brands want to help the environment. If you care about being green, pick a manufacturer who uses eco-friendly materials and fair labor. This can help your brand stand out and get loyal customers.

Tip: Write down what your brand must have before you talk to any manufacturer. This will save you time and help you find the best match.

When you know your brand’s level, product needs, and priorities, you can choose a manufacturer who helps your brand grow. Take time to think about these things. Your brand’s future depends on it.

California Knitwear Manufacturer Landscape

When you look for a california knitwear manufacturer, you will see many choices. There are different clothing manufacturers in California. Each one gives special services and fits certain brand needs. Let’s talk about what you might find.

Types of Manufacturers

Full-Service Factories

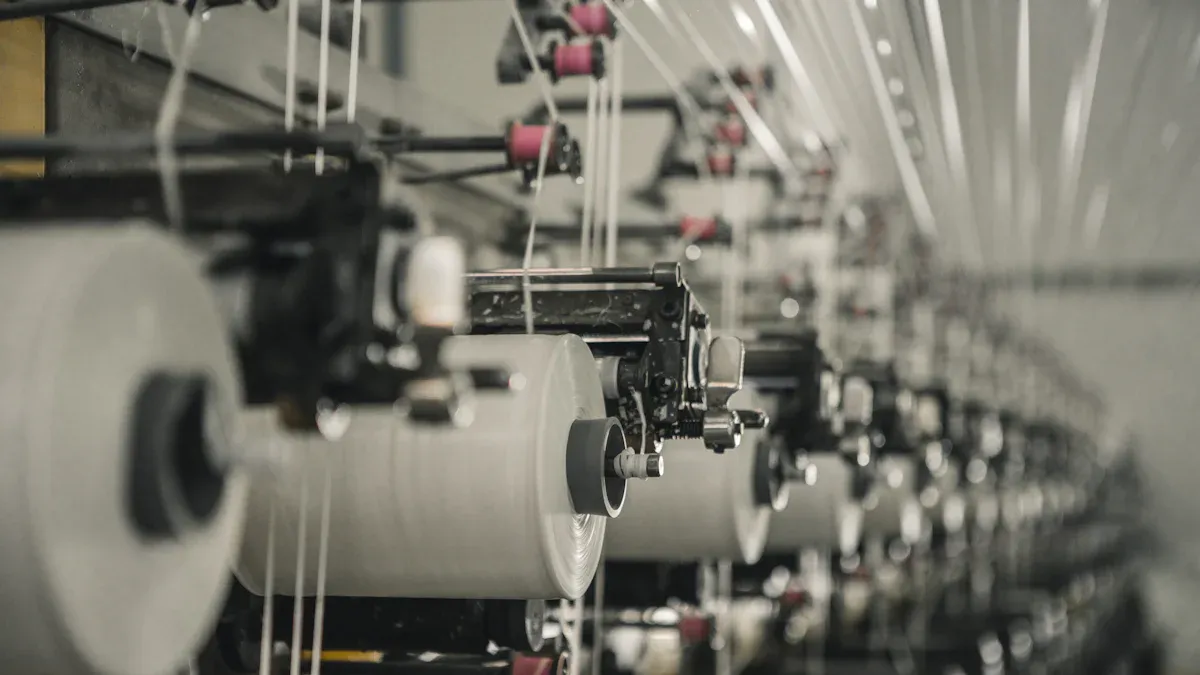

Full-service factories do everything from design to delivery. You send your ideas, and they handle the rest. These clothing manufacturers have big teams and modern machines. They work with yarns like cotton, wool, synthetic blends, organic cotton, and recycled materials. You can pick stitches like flat knitting, rib stitch, cable stitch, and jacquard. They use 3GG machines for heavy knits and 7GG or 12GG machines for lighter clothes. Quality assurance is very important for these apparel manufacturers. They check materials, watch products during production, and inspect finished items. Some even use third-party agencies for extra checks.

Small-Batch Studios

Small-batch studios make small runs and special projects. If you want to try new designs or keep your brand unique, these clothing manufacturers are a good choice. They give personal service and help startups or niche brands. You get more control over each item, and they often use hand-finishing. Small-batch studios do not have as much production power as full-service factories. But they pay close attention to details.

Here’s a quick look at what these manufacturers offer:

Category | Details |

|---|---|

Yarn Types | Cotton, Wool, Synthetic Blends, Organic Cotton, Recycled Materials |

Stitch Types | Flat Knitting, Rib Stitch, Cable Stitch, Jacquard |

3GG Machines for heavier knits, 7GG and 12GG Machines for lightweight to medium-weight garments | |

Quality Assurance | Material Inspection, In-Process Quality Checks, Final Product Inspection |

Third-Party Inspection | Collaboration with recognized agencies, Detailed reports for clients |

Local Expertise

Industry Knowledge

California knitwear manufacturer teams know a lot about making clothes. You will find clothing manufacturers who care about quality and luxury. Some, like The Elder Statesman, use hand-spun materials and old methods. This makes their products different from other apparel manufacturers. You get special, high-quality pieces that show your brand’s style.

Market Trends

California knitwear manufacturer groups keep up with new trends. Here’s what is important in 2025:

More focus on sustainability in knitwear.

New technology changing how clothes are made.

People want luxury and useful knitwear.

Pros and Cons

Proximity

Working with a california knitwear manufacturer means you are close by. Local clothing manufacturers can react fast to changes. You do not wait for customs or long shipping. Your products arrive faster, and you can visit the factory.

Lead Times

Speed is a big plus, but there are problems too. High costs make it hard for some clothing manufacturers to compete with overseas factories. Trinity Knitworks had money problems and lost to cheaper labor markets. You need to think about fast lead times and your budget.

Tip: Visit local apparel manufacturers if you can. Seeing how they work helps you learn their strengths and problems.

Picking the right california knitwear manufacturer means knowing what each type does. You get better results when you match your brand’s needs with the right clothing manufacturers.

Key Criteria for Best Clothing Manufacturer

Picking the best clothing manufacturer is about more than price. You need a partner who makes good products and keeps promises. They should help your business grow. Let’s look at what matters most.

Production Quality

Your knitwear should look and feel great. The best clothing manufacturer cares about quality. They follow rules and check each step.

Standards & Certifications

Check if the manufacturer meets important standards. These rules protect your brand and customers. In California, garment manufacturers must register with the labor commissioner. They show their registration certificate for everyone to see. The Garment Worker Protection Act makes sure workers get fair pay and clear records.

Many top manufacturers get extra certifications. These prove they care about safety, the planet, and people. Here are some you might see:

GOTS (Global Organic Textile Standard): Uses organic materials and safe processes.

OEKO-TEX® Standard 100: Makes sure fabrics are safe and free from bad chemicals.

Bluesign®: Focuses on safe chemical use and less waste.

Cradle to Cradle: Shows products can be recycled or reused.

Fair Wear Foundation, SA8000, WRAP: Checks that workers have good conditions and fair treatment.

Higg Index: Measures how factories treat the environment and workers.

You can also look at this table to see what California needs:

Requirement | Description |

|---|---|

Registration | Manufacturers must register with the California labor commissioner and show their certificate clearly. |

Garment Worker Protection Act | Makes sure garment workers get at least minimum wage and sets recordkeeping rules for manufacturers. |

Tip: Ask every clothing manufacturer for proof of their certifications. This helps you avoid problems later.

Sample Review

Always ask for samples before you order a lot. The best clothing manufacturer will send samples that match your designs. You can check the quality, feel the fabric, and see the stitching. This helps you find problems early.

Manufacturers in California use checkpoints to keep quality high. Here’s how they do it:

Checkpoint Category | Description |

|---|---|

Production Control | Checks for accuracy, finds defects, and keeps work consistent during manufacturing. |

Shipment Control | Checks labeling, packaging, final quality, and paperwork before shipping. |

If you see mistakes in the sample, talk to the manufacturer. Good garment manufacturers fix problems quickly. This shows they care about your brand.

Cost-Effectiveness

You want the best mix of cost and quality. The best clothing manufacturer helps you save money but keeps quality strong. Let’s see how you can check if a manufacturer is cost-effective.

Pricing Structure

Ask each manufacturer how they set prices. Some charge by the piece, others by the hour or project. Make sure you know what is included. Does the price cover materials, labor, and shipping? Are there extra fees for rush orders or special yarns? The best clothing manufacturer explains everything clearly.

You can compare prices from different manufacturers. Make a simple table to see which one gives you the best deal. Remember, the lowest cost is not always the best choice. You want good value and strong quality.

Payment Terms

Payment terms change how you manage your money. The best clothing manufacturer offers clear and fair payment options. Here are some ways you might pay:

Letter of Credit (L/C): Your bank promises to pay when the manufacturer delivers.

T/T (Telegraphic Transfer): You pay part up front and the rest after you check the goods.

Open Account: You pay later, after you get the products.

Documentary Collections: Banks help with payment, but it is less safe than L/C.

Cash in Advance (CIA): You pay before the manufacturer starts work.

Consignment: You pay only when you sell the garments.

Net Terms: You pay within a set time after getting the invoice.

CAD (Cash Against Documents): You pay when you get the shipping papers.

Revocable or Irrevocable L/C: Different types of letters of credit with different rules.

Confirmed or Unconfirmed L/C: Some have extra bank promises, some do not.

Note: Pick payment terms that fit your cash flow and trust level with the manufacturer.

Reliability

You need a partner you can trust. The best clothing manufacturer keeps promises and delivers on time. Reliability helps your brand grow and keeps your customers happy.

Track Record

Ask the manufacturer about their past work. Have they worked with brands like yours? Do they have happy clients? The best clothing manufacturer shares stories, shows finished garments, and gives references. You can check reviews online or ask for a portfolio.

Meeting Deadlines

Deadlines are important. If your products arrive late, you lose sales and trust. The best clothing manufacturer meets deadlines. They plan ahead, keep you updated, and fix problems fast. If you need changes, they stay flexible and help you adjust.

Callout: Always ask for a timeline before you start. Good manufacturers will give you clear dates for every step.

When you look for the best clothing manufacturer, focus on these key criteria. You want great production quality, fair cost, and a partner you can trust. This helps your brand stand out and grow strong.

Lead Times

Speed to Market

You want your knitwear to get to customers fast. California knitwear manufacturers help you move quickly. Some factories, like Knitwise, finish custom knitwear in just 2–4 weeks. This is much faster than the old way, which could take 4–8 weeks or longer. Most garment factories start counting lead time when you pay the fabric deposit. If you order a lot of pieces, delivery can take up to 60 days.

Fast lead times let you test new designs and react to trends. You can keep your shop full without waiting months for products. This speed gives your brand an edge. It helps if you want to launch new collections often.

Tip: Ask each manufacturer how long it takes from order to delivery. Fast lead times help you stay ahead of your competition.

Flexibility

You need a manufacturer who can change plans when needed. California knitwear factories are known for being flexible. They handle quick turnarounds and adjust their plans for you. If you want a small batch, some factories deliver finished goods in under two weeks.

Here are ways California manufacturers show flexibility:

They change production strategies for your brand’s needs.

They can make small orders (like 150 pieces) or thousands of units.

Multiple shifts and facilities help them handle different order sizes.

They make changes to keep quality and efficiency high as your brand grows.

This flexibility helps new and established brands. You can start small and grow bigger without switching factories. If you need to change your order or timeline, your manufacturer can usually help.

Sustainability

Eco-Friendly Practices

You want your brand to be good for the planet. Many California knitwear manufacturers use eco-friendly practices. They use recycled cotton-poly blends made from old clothes. They also use organic cotton, which is grown without harmful chemicals. This keeps the earth and workers safe.

California factories keep improving their green efforts. They use new technology to make fabric finishes with natural materials. They care about packaging and waste. Many use eco-friendly packaging and try to reduce waste at every step.

Here’s a look at common sustainable practices:

Sustainable Practice | Description |

|---|---|

Use of organic and recycled fabrics | Organic cotton is grown without harmful chemicals. Recycled blends use old clothes, cutting textile waste. |

Innovative production processes | Factories use technology for safer fabric finishes and better waste management. |

Eco-friendly packaging and waste reduction | Factories use green packaging and work to make less waste. |

You get softer, hypoallergenic fabrics when you choose organic cotton. This supports fair labor and better farming. Your customers will notice and appreciate your care for the environment.

Ethical Labor

You want to know that workers are treated well. Many garment workers are women between 18 and 35 years old. Sadly, most earn less than $3 a day in many places. California is working to change this.

The FABRIC Act helps protect workers. It sets rules for fair pay and stops wage theft. Factories must pay workers by the hour, not by the piece. This creates better jobs and helps families.

“By proactively addressing the pressing labor and worker issues they face—from ensuring fair wages and a safe working environment to ending discrimination and gender-based violence—we can create lasting and transformative impact on their lives, communities and the sector.”

When you choose a California knitwear manufacturer, you support fair wages and safe workplaces. Your brand stands for more than style. You help build a better future for workers and their families.

Evaluating and Selecting Manufacturers

Picking the right manufacturer is not easy or quick. You need someone who fits your needs and delivers on time. The right choice helps your brand look its best. Here are some steps to help you choose wisely.

Research Methods

Online Directories

Start by using online directories. These websites list many California knitwear manufacturers together. You can search by location, services, or what they do best. Some good directories are Maker’s Row, ThomasNet, and Sewport. These sites let you read reviews and compare services. You can also contact manufacturers right from the website. This saves you time and helps you find the best ones for your brand.

Search Engines

Search engines like Google are also helpful. Type in what you want, like “California knitwear manufacturer for small batch.” You will see company websites, news, and social media. Look at their websites for photos and client lists. Check if they update their site and post on social media. This shows they are active and care about their business.

Tip: Make a list of manufacturers you like. Write down their contact info, what they offer, and any notes about their strengths.

Shortlisting

After you make a list, you need to narrow it down. Not every manufacturer will be right for you. Here is how you can compare your choices.

Comparing Options

Look at more than just the price. Think about quality, where they get their materials, and how much they can make. Here is a table to help you compare:

Criteria | Description |

|---|---|

Quality | Fabrics are tested and meet standards of major retailers, ensuring high quality. |

Sourcing | Reliable suppliers with certifications ensure timely deliveries and consistent fabric quality. |

Production Capabilities | Facilities operate 5 to 7 days a week, using advanced machinery for efficient production. |

You can also use this checklist:

Pick top-quality fabrics from good suppliers.

Make sure suppliers have the right certifications.

Choose suppliers who deliver on time.

Ask each manufacturer if they have worked with brands like yours. Find out if they can make your designs and use your materials. If you want eco-friendly choices, ask if they have organic or recycled yarns.

Minimum Orders

Minimum order quantity, or MOQ, is important. Some manufacturers want big orders, but others allow small ones. Here is a table showing how MOQs can be different:

Manufacturer | Minimum Order Quantity | Notes |

|---|---|---|

LA Fashion Source | Varies | Specializes in high-volume quantities; flexible for startups and established brands. |

Mona Lisa Manufacturing | Flexible | Supports smaller production runs for emerging designers and established brands. |

Made Apparel Services | Flexible | Allows sample batches for market testing before larger production runs. |

TEG | No MOQ | No minimum order required for custom clothing; orders can scale from 50 to 300+ pieces. |

SL Sportswear | 150 pieces | Accommodates small batch production for fitness apparel startups. |

Apparel Kingdom | 30 pieces | Ideal for testing new product lines with low capital requirements. |

If you are new, pick a manufacturer with a low MOQ. This lets you try your ideas without spending too much. If you want to grow fast, choose someone who can make bigger orders later.

Sampling & Quotes

Before you decide, you should see and feel the quality. Sampling and quotes help you avoid problems.

Sample Requests

Ask each manufacturer for a sample of your design. Most California knitwear manufacturers use 3D systems for digital sampling. You can get a sample in just 3–5 days. This lets you check the fabric, fit, and stitching before you order a lot.

Here is what the process looks like:

Step | Details |

|---|---|

Minimum Order Quantity | Starts from 50–80 pieces per style, depending on the manufacturer. |

Sampling Time | 3–5 days for digital or 3D knit simulation samples. |

Lead Time for Production | 3 weeks to 25 days for bulk production, depending on the order size. |

Payment Methods | T/T, L/C, and Alibaba Trade Assurance for secure transactions. |

If you like the sample, you can order more. If not, ask for changes or try another manufacturer.

Quote Comparison

Always ask for a quote that lists all costs. This should include price per piece, setup fees, shipping, and extras. Compare quotes from different manufacturers side by side. Do not just pick the lowest price. Think about quality, speed, and service. A good manufacturer will explain their prices and answer your questions.

Note: Clear quotes and fast samples show a manufacturer is organized and values your business.

These steps help you find a manufacturer that fits your brand. You save time, avoid mistakes, and help your brand succeed.

Factory Visits

Visiting a factory helps you see how things really work. You get to check the machines, meet the team, and watch your knitwear being made. You can choose to visit in person or take a virtual tour. Both ways give you a better idea of what to expect.

Onsite Tours

Walking through a factory gives you a close look at the process. You can touch the fabrics, see the machines, and talk to the workers. You notice how clean the space is and how the team works together. You might spot things you like or things you want to change.

Here’s what you can do during an onsite tour:

Watch how workers handle your materials.

Check if the factory follows safety rules.

Ask questions about each step of production.

Look for signs of good organization, like clear labels and tidy workspaces.

Notice how the staff treats each other.

Tip: Bring a checklist with you. Write down what you want to see and ask. This helps you remember important details later.

If you can, visit more than one factory. You will see the differences and find the best fit for your brand.

Virtual Tours

Sometimes you can’t visit in person. Many California knitwear manufacturers now offer virtual tours. You can join a video call and see the factory from your computer or phone. The staff will walk you through the space and show you how things work.

Virtual tours help you:

Save time and travel costs.

See the machines and work areas live.

Ask questions in real time.

Watch how workers make your products.

You can also ask for videos or photos if a live tour is not possible. This way, you still get a good look at the factory.

Note: Always ask to see the parts of the factory that matter most to you, like the knitting machines or packing area.

References

Checking references gives you the inside scoop on a manufacturer. You learn what it’s really like to work with them. Good references can save you from big mistakes.

Client Feedback

Talking to other brands who have worked with the manufacturer helps you a lot. You get honest answers about what went well and what didn’t. Here are some things you should ask about:

Delivery reliability: Did the manufacturer ship on time?

Problem resolution: How did the factory handle mistakes or delays?

Communication: Was it easy to get updates and answers?

Product quality: Did the finished knitwear meet their standards?

Flexibility: Could the manufacturer handle changes or special requests?

You can call or email past clients. Most will be happy to share their experience. Listen for any red flags, like late orders or poor communication.

Callout: Always ask for at least two or three references. This gives you a clearer picture of what to expect.

Portfolio Review

A portfolio shows you what the manufacturer can do. You get to see real samples of their work. Look for styles, stitches, and materials that match your brand.

Here’s how to review a portfolio:

Ask for photos or physical samples of past projects.

Check if they have made products like yours.

Look at the details—stitching, finishing, and labels.

Notice the range of styles and quality.

A strong portfolio means the manufacturer has experience. You can trust them to bring your ideas to life.

Tip: If you see something you like in their portfolio, ask how they made it. This helps you understand their skills and process.

Taking time to visit factories and check references helps you pick the right partner. You get peace of mind and set your brand up for success.

Building Manufacturer Relationships

Building a strong relationship with your California knitwear manufacturer helps your brand grow. Good partnerships lead to better products, fewer mistakes, and smoother production. Let’s look at how you can build trust and work well together.

Communication

Clear communication keeps your projects on track. When you talk openly with your manufacturer, you avoid confusion and delays. You both understand what needs to happen next.

Responsiveness

Quick replies show you care about the partnership. If you answer emails and calls fast, your manufacturer will do the same. This helps you solve problems before they grow. You can ask questions, share updates, or check on your order. Fast responses keep everyone moving forward.

Transparency

Honesty builds trust. Share your goals, timelines, and any changes right away. If you spot a problem, talk about it early. Your manufacturer will respect your openness. They will also share updates about production or delays. This way, you both stay on the same page.

Tip: Respect your manufacturer’s expertise. When you listen to their advice, you show you value their skills.

Here are some ways to keep communication strong:

Avoid angry language or a condescending tone.

Be prepared and clear about your needs.

Show trust to get trust in return.

Address problems in a calm, constructive way.

Collaboration

Working together makes your products better. When you team up with your manufacturer, you get new ideas and better results.

Design Support

Share your design ideas early. Ask for feedback on what works best. Your manufacturer can suggest changes to improve fit or style. They know what looks good and what sells well. This teamwork helps you create knitwear your customers will love.

Technical Help

Sometimes you need help with materials or machines. Your manufacturer can guide you through tricky parts of production. They might suggest new yarns or better ways to knit your designs. This support saves you time and money.

Collaboration can lead to new technology, like 3D fabric weaving, which reduces waste and boosts efficiency.

Ongoing teamwork helps you stay ahead of trends and grow your brand.

Long-Term Success

A good relationship with your manufacturer helps your brand last. You both want to succeed, so you work together to solve problems and plan for the future.

Partnership Growth

As your brand grows, your manufacturer can help you scale up. They might offer new services or faster production. You can test new ideas together and reach more customers.

Problem Solving

Every business faces challenges. When you trust your manufacturer, you can fix problems quickly. Talk openly about issues and work together on solutions. This keeps your brand strong and your customers happy.

Building a strong partnership takes time, but it pays off. Choose the right partner, communicate clearly and often, and respect their expertise. Your brand will thank you.

Practical Tips for Different Brand Goals

Every brand wants different things. Some want to save money. Others want the best quality. Some brands want to get bigger. Here are some easy tips to help you work with your California knitwear manufacturer.

Cost Control

Saving money helps your brand stay strong. You do not have to lose quality to spend less. Try these ideas:

Negotiation

You can talk to your manufacturer about prices. Ask them for clear price quotes. See if you get a better deal for bigger or repeat orders. Sometimes, you can pay less if you use more common yarn or colors. Always ask about payment rules. Some factories give discounts if you pay early.

Reducing Waste

Cutting waste saves money and helps the earth. You can:

Make your production steps simple and smooth.

Use leftover yarn for samples or small things.

Pick designs that use fabric well.

Choose green practices to save money and please customers.

Teach your team to make fewer mistakes.

Tip: When you waste less, you save money and show you care about the planet.

Quality Assurance

Good quality makes customers come back. You want every piece to look and feel nice. Here’s how you can make sure your knitwear is always good.

Quality Control

Check your products often while they are made. Look for problems early. Fix them before they get worse. Good checks mean fewer returns and happy customers. You can also ask your manufacturer how they check quality.

Quality Assurance Measure | Description |

|---|---|

Check products often to find problems early. | |

Ethical and Sustainable Practices | Fair work and less waste make people trust your brand. |

Continuous Improvement | Keep making your standards better with new ideas. |

Enhanced Customer Satisfaction | Happy customers come back and tell friends. |

Improved Brand Reputation | Good quality makes your brand look great. |

Cost Savings | Good checks save money by stopping waste and rework. |

Compliance and Safety | Meeting rules keeps your products safe and legal. |

Higher Market Competitiveness | Good quality helps you beat other brands. |

Longevity of Products | Strong knitwear keeps customers coming back. |

Consistency

You want every item to be the same. Use the same materials and patterns each time. Give clear instructions to your manufacturer. Work together to stop surprises. Consistency helps customers trust your brand.

Scaling Up

When your brand gets bigger, you need to be ready. Planning helps you handle more orders without stress.

Production Capacity

Ask your manufacturer how much they can make. Can they do more if you get lots of orders? Some factories can add more workers or machines. Make sure they have enough space and people to grow with you.

Planning Growth

Think ahead about your brand’s future. Tell your manufacturer your plans to grow. Work together to set dates and plan new styles. If you plan early, you will not have delays and your customers will be happy.

Remember: Good planning, strong quality, and smart spending help your brand win at any stage.

Making the Final Choice

Choosing your California knitwear manufacturer feels like a big step. You want to make sure you pick the right partner for your brand. Let’s break down how you can make this decision with confidence.

Weighing Pros and Cons

You have a shortlist of manufacturers. Now, it’s time to compare them side by side. You want to look at what each one offers and what might be a drawback.

Decision Matrix

A decision matrix helps you see things clearly. You can list important factors and score each manufacturer. Here’s a simple table to get you started:

Factor | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

Production Time | ⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ |

Minimum Order (MOQ) | ⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ |

Customization | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ |

Sustainability | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ |

Customer Service | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ |

Product Quality | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ |

You can use stars, numbers, or notes. This makes it easy to see which manufacturer fits your brand best.

Tip: Don’t just look at price. Think about how fast they work, how many pieces you need to order, and how much they help you customize your designs.

Here are some things you should consider:

Production time

Minimum order quantities (MOQ)

Sustainability practices

Customer service

Product quality

Customer service matters a lot. If your manufacturer answers quickly and solves problems, you save time and money. Good service helps you build a strong brand and keeps your customers happy. Sustainability is also key. When your manufacturer uses green practices, you help the planet and make your business last longer.

Team Input

You don’t have to decide alone. Ask your team for their thoughts. Maybe someone notices a detail you missed. You can hold a meeting and talk about each manufacturer. Everyone can share their opinions and vote. This way, you make a choice that feels right for your whole brand.

Agreements

Once you pick your manufacturer, you need to set up clear agreements. This protects you and helps things run smoothly.

Contracts

A contract spells out what you expect. It lists prices, delivery dates, quality standards, and payment terms. You want everything in writing so there are no surprises. If you have special requests, add them to the contract. Both you and your manufacturer sign it. This makes your partnership official.

Note: Always read your contract carefully. Ask questions if something isn’t clear.

Onboarding

Onboarding is the first step in working together. You share your designs, timelines, and brand story. Your manufacturer learns what you want. You set up how you’ll communicate and solve problems. A good onboarding process helps you start strong and avoid mistakes.

You’re ready to bring your knitwear ideas to life. Take your time, trust your process, and choose the partner who fits your brand best.

You now have the tools to pick the best California knitwear manufacturer for your brand. Take your time, ask questions, and trust your gut. Remember these steps:

Know your brand’s needs

Check quality and values

Build a strong partnership

Great knitwear starts with the right partner. Ready to make your vision real? Go for it! 🚀

FAQ

What is the typical minimum order quantity (MOQ) for California knitwear manufacturers?

Most California knitwear manufacturers ask for 30 to 150 pieces. Some studios let startups order even fewer pieces. Always check their MOQ before you begin your project.

How long does it take to produce custom knitwear in California?

Production takes about 2 to 6 weeks after you approve your sample and pay your deposit. Some factories can make your order faster if you need it quickly.

Can I visit the factory before placing an order?

Yes, many manufacturers let you visit in person or online. You can look at their machines, meet the team, and see how they check quality. This helps you feel sure about your choice.

Do California knitwear manufacturers offer eco-friendly options?

Yes! Many use organic cotton, recycled yarn, and green packaging. You can ask for certifications like GOTS or OEKO-TEX® to make sure your products are eco-friendly.

What should I include in my tech pack for knitwear production?

Your tech pack should have:

Clear sketches or photos

Fabric and yarn details

Color choices

Size chart

Stitch type

Tip: Give lots of details so your samples match your ideas.

How do I handle quality issues with my manufacturer?

If you find a problem, tell your manufacturer right away. Send photos and explain what went wrong. Good partners fix mistakes fast and help you stop them from happening again.

Can I start with a small order and scale up later?

Yes! Many California manufacturers let you begin with a small order. As your brand gets bigger, you can order more pieces. This helps you test your designs and control your spending.