You need a knitted garments manufacturer that matches your business goals. If you want to control the design and have something special, custom clothing is best. Custom options cost more and take longer to make. But they help you create a brand that is different. Private label clothing lets you start selling faster and spend less money. You use designs that are already made and order in large amounts. Pick what fits your money and your brand idea. This helps you choose with confidence.

Key Takeaways

Custom clothing gives you full control over the design. You can make special clothes that show your brand.

Private label clothing is faster to get started. You can sell products quickly with ready-made styles.

Think about your money. Custom clothing usually costs more. Private label is cheaper and saves money.

Custom clothing needs you to order more items at once. Private label lets you order fewer, which helps new businesses.

Quality control is very important. Custom manufacturing lets you check every detail. Private label keeps quality steady with set rules.

Think about what your business wants. Pick custom for a special look and strong brand. Pick private label for speed and easy changes.

Use technology and good planning to help with speed and custom choices in making your clothes.

Always ask makers for a full list of costs. This helps you avoid surprise fees and stay on budget.

Knitted Garments Manufacturer Options

What Is Custom Clothing Manufacturing

When you pick custom clothing manufacturing, you get full control. You choose the yarn, like soft wool or cashmere. This choice changes how your clothes feel and last. You can pick special knitting styles, like cable stitches or lacework. These make your clothes look different. Custom clothing manufacturers use special machines and skilled workers. They make each piece from your ideas. You can ask for seamless designs or special patterns. This takes more time and costs more money. But you get clothes that match your ideas and are high quality. Custom manufacturing helps you build a brand that is unique.

Tip: Custom clothing is best if you want something unique and have a clear brand idea.

What Is Private Label Manufacturing

Private label manufacturing is a faster and easier way to start your brand. You pick from styles the knitted garments manufacturer already makes. You can add your own label and sometimes change small things, like colors or trims. Private label clothing usually lets you order less at one time. You spend less money because you skip long design steps. Production is quick, so you can sell sooner. Private labeling is good if you want to test the market or grow your business without spending a lot at first. You do not get as much control over the design, but you save time and money.

Pre-designed styles let you pick from ready-made choices.

Lower minimum orders help you save money.

Fast turnaround lets you launch new products quickly.

You spend less on design and samples.

You have less control over design and fabric.

Key Differences Overview

You should know how custom clothing and private label are different before you choose. The table below shows the main differences:

Aspect | Custom Clothing | Private Label |

|---|---|---|

Manufacturing Process | You design each garment from scratch. | You choose from ready-made styles. |

Design | Full control over every detail. | Limited to existing designs. |

Production Stages | Many steps, including sampling and quality checks. | Fewer steps, products are pre-made. |

Cost | Higher investment for unique pieces. | Lower costs with bulk pricing. |

Minimum Order Quantities | Usually higher, set by the manufacturer. | Lower, more flexible. |

Time to Market | Longer due to custom work. | Faster, products are ready to sell. |

Custom clothing manufacturing gives you the most choices and makes your brand special. You can use special yarns and knitting styles to make your clothes stand out. Private label clothing lets you move fast and order less, but you use set designs. Private label is a mix because you get some control but not as much as custom clothing. If you want to make lots of clothes fast, private label is a good choice. If you want every detail to match your ideas, pick custom clothing. Think about your brand goals, your budget, and how much control you want over making your clothes.

Design Flexibility & Uniqueness

Custom Clothing Manufacturers’ Capabilities

Custom clothing gives you the most freedom to design. You can start with your own ideas and make each detail how you want. You get to pick the fabric, the fit, and even small finishes. You can choose the yarn and the cut. You can ask for special knitting patterns or custom features. This helps your clothes look just how you want. Your brand can stand out because you control everything.

Here is a quick comparison of what you can do with custom clothing versus private label:

Feature | Custom Clothing Manufacturers | Private Label Manufacturers |

|---|---|---|

Customization | Extensive customization options | Limited to existing designs |

Control over production | Less control over design | |

Unique design elements | Yes | No |

With custom clothing, you can make something new. You do not have to copy other brands or follow trends. Your clothing line can be different from others.

You can pick fabrics, cuts, fits, and finishes.

You can make clothes from your own ideas.

You can help your line stand out in the market.

Private Label Clothing Customization

Private label clothing is fast and flexible. You start with styles the manufacturer already has. You can change things like colors, trims, or add your logo. You can also pick special packaging or embroidery. This lets you add your brand’s style without starting from nothing.

Here are some ways you can customize private label clothing:

Customization Service | Description |

|---|---|

Knitting | Tailor knit patterns and textures to your brand. |

Cutting | Custom cutting for special designs. |

Sewing | Assemble garments to fit your needs. |

Dyeing | Match your brand colors with custom dyeing. |

Screen Printing | Print your designs or logos on garments. |

Sticker Printing | Add stickers for branding. |

Special Packaging | |

Embroidery | Add embroidered logos or designs. |

You can use new technology to make your clothes. The process is quick and can change to fit your needs. You can make your brand special.

Note: Private label clothing gives you more design choices than white label. You can pick fabrics, colors, and special touches to make your products stand out.

Brand Differentiation

Your choice changes how your brand stands out. Custom manufacturing gives you the most ways to be different. You can make designs that no one else has. This helps your brand get noticed and keeps customers coming back.

Private label clothing also helps your brand be unique. You get products made just for your brand. You can change many things, so your brand is not like others. You can pick the design and fabric. This makes your brand special in the market.

Private label products are made for your brand only.

You get a special identity and can beat other brands.

You can control design and quality for a stronger brand.

If you want your brand to be different, think about how much control you want. Custom clothing gives you full freedom. Private label gives you speed and some choices.

Minimum Orders & Scalability

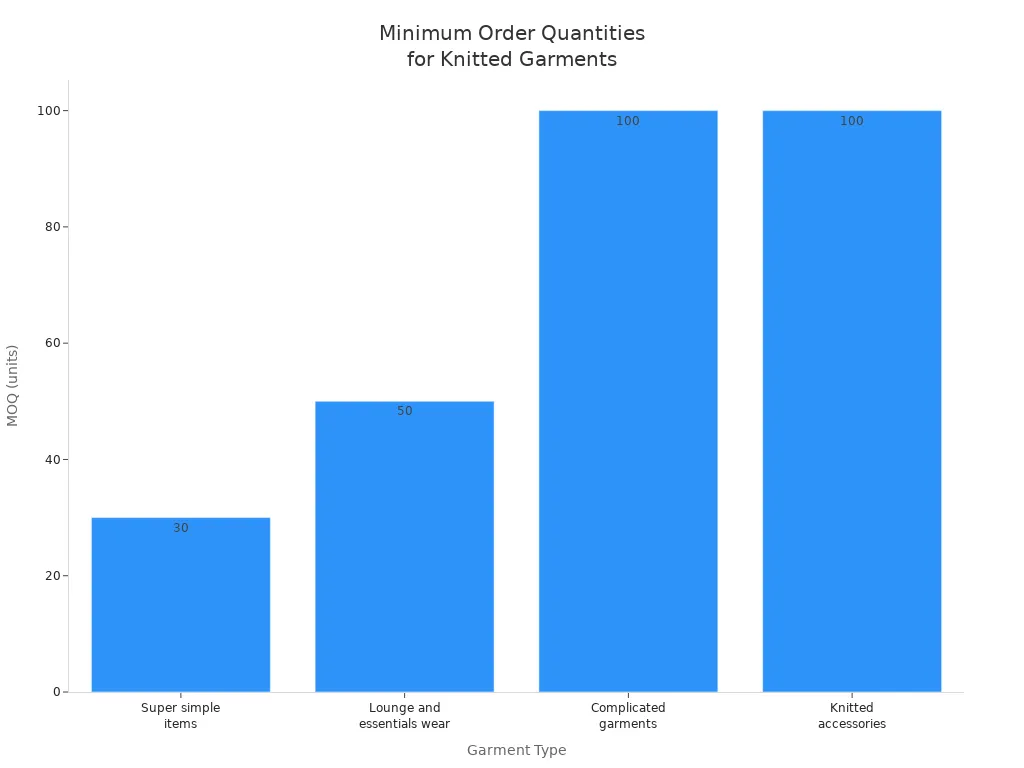

Custom Clothing Manufacturing MOQs

When you pick custom clothing, you must order a set amount. This is called the minimum order quantity, or MOQ. MOQs show how many pieces you need for each style. Custom clothing usually needs higher MOQs. Each item is made just for you. Makers must set up machines and get special materials. This takes extra time and work.

Here is a table that shows MOQs for different knitted garments:

Garment Type | Minimum Order Quantity (MOQ) |

|---|---|

Super simple items | 30 units |

Lounge and essentials wear | 50 units |

Complicated garments (e.g., trousers with fly-front zip) | 100 units |

Knitted accessories (e.g., socks) | 100 units |

Simple items need fewer pieces. Harder designs need more. Custom clothing gives you control. You must order more, especially for detailed styles.

Tip: Always check the MOQ for each garment before you start custom manufacturing.

Private Label Clothing MOQs

Private label lets you order fewer pieces. You pick styles the maker already has. You can test new products with less money. Private label helps you start small and grow as you get more buyers. You do not need to design everything. The process is faster and easier.

Private label clothing has flexible MOQs. You might order just 30 units for simple items. You can try new colors or sizes without a big order. Private label helps you save money and lower your risk.

Start with small orders and grow as you need.

Try new styles without spending a lot.

Change quickly when the market shifts.

Note: Private label is great if you want to try new things or launch products fast.

Growth & Scalability

MOQs affect how your business can grow. High MOQs in custom clothing make it hard to test new ideas. You must spend more and keep more stock. This can slow you down if you are new.

Private label gives you more freedom. Lower MOQs let you test new designs and change your products fast. You can grow step by step and waste less. This is good for startups and online shops. You can change with what buyers want and grow at your own speed.

Block Quote: Lower MOQs help you grow slowly and try new designs. This is important for new brands and online stores that need to change quickly without spending too much.

If you want a special brand and have enough money, custom clothing is best. If you want to grow fast and spend less, private label helps you grow with less risk.

Cost & Pricing Structure

Upfront & Development Costs

You need to plan for upfront costs before you start production. Custom clothing usually has higher development costs. You pay for design work, pattern making, and samples. These steps help you create something unique. You may spend more at the start, but you get full control over your product.

Private label has lower upfront costs. You pick from ready-made designs. You do not pay for new patterns or long design meetings. Private labeling lets you start your brand with less money. You can launch products faster because you skip many steps.

Tip: If you want to test the market or save money, private label is a smart choice.

Per-Unit Pricing

The price you pay for each item depends on your order size and the type of manufacturing. Custom clothing often costs more per piece. You pay for special materials, custom work, and small batches. If you order more, the price per unit can go down. Still, custom manufacturing stays more expensive than other options.

Private label gives you better prices for larger orders. You use designs the factory already makes. This saves time and money. You can get wholesale and oem pricing if you order in bulk. This helps you keep costs low and sell at a good price.

Custom clothing: Higher per-unit cost, best for unique products.

Private label: Lower per-unit cost, best for growing your brand.

Hidden Costs

You should watch out for hidden costs in both custom clothing and private label. These costs can surprise you if you do not plan ahead. Here is a table that shows common hidden costs and what you might pay:

Hidden Cost Type | Estimated Cost Range | Notes |

|---|---|---|

Sampling & Development Fees | $50–$200 per design | Varies by complexity; some fees refundable |

Quality Assurance & Inspection | $80–$300 per order | Costs for in-line QC and lab testing |

Packaging Materials & Branding | N/A | Additional costs for branding elements |

Sampling and development fees can add up, especially for custom clothing. You may need to pay for each new design. Quality checks and lab tests also cost extra. If you want special packaging or branding, you pay more. These costs apply to both private label and custom clothing.

Note: Always ask your manufacturer for a full cost breakdown. This helps you avoid surprises and plan your budget.

You can make a smart choice if you know all the costs. Custom clothing gives you control and quality. Private label helps you save money and grow fast.

Time to Market

Custom Clothing Lead Times

You need to plan for longer timelines when you choose custom clothing. Each step takes time because you start from scratch. You work with the manufacturer to create your own designs. You wait for samples, approve them, and then start production. Shipping also adds days to your schedule. Here is a table that shows the average lead times for custom clothing:

Stage | Estimated Time |

|---|---|

Production | 7–14 days |

Shipping – Economy | 7–14 days |

Shipping – Express | 3–5 days |

Total Timeline |

You see that custom clothing can take two to four weeks from order to delivery. If you want special features or complex designs, you may wait even longer. You get unique products, but you need patience.

Private Label Manufacturing Speed

Private label helps you move faster. You pick from styles that are ready to produce. You do not need to wait for new patterns or long design meetings. Lead times for private label clothing can range from eight to twenty-four weeks. The time depends on where the factory is, how many pieces you order, and what materials you choose. You can often launch your products quickly because the main designs are already set.

You choose a style.

The manufacturer starts production right away.

You get your finished products faster than with custom clothing.

Private label works well if you want to test the market or respond to trends. You can restock popular items without long delays.

Balancing Speed & Customization

You can find ways to balance speed and customization. Many brands use smart tools to help with this. AI can help you manage fabric use and energy. It can also help you keep track of inventory. These tools make production faster and help you get the features you want. You can also focus on eco-friendly practices. This attracts customers who care about the planet and lets you charge more for your products.

Use AI to plan your orders and reduce waste.

Choose factories that use efficient production methods.

Pick sustainable materials to stand out in the market.

Tip: You do not have to choose between speed and quality. Smart planning and the right partners help you get both.

When you know your goals, you can pick the best path. Custom clothing gives you full control but takes more time. Private label lets you launch quickly and adjust to the market. Use technology and good planning to get the best of both worlds.

Branding & Identity

Customization for Brand Identity

You want your brand to be noticed. Custom clothing manufacturing helps you make a strong brand. You can design every part of your knitted garments. You pick the yarn, the fit, and the patterns. You can even choose special details, like cool buttons or trims.

Customers today want brands to offer custom choices. They like clothes that match their style and fit well. Many people look for limited edition and special designs. Custom manufacturing lets you give them what they want.

Customization shows your brand’s story.

You can offer special fits and cool designs.

Unique pieces help you get customers who want something different.

Custom manufacturing helps you build a brand that feels special and personal.

Private Label Clothing Branding

You can also make your brand strong with private label clothing. Manufacturers give you many ways to make your products look unique. You do not design the whole garment, but you can add your own style.

Here are some branding options you can pick:

Branding Option | Description |

|---|---|

Custom Woven Tags | Woven into the fabric for brand identification. |

Custom Heat Transfer Printed Labels | Used for care instructions and size display. |

Screen Printed Labels | Flexible printed labels for branding. |

Sublimation Printed Labels | For product identification and warnings. |

Satin Care Labels | Show material and washing instructions. |

Custom Steel Embossed Labels | Unique tactile branding option. |

Tyvek Labels | Lightweight and durable for many uses. |

Cotton Fabric Labels | Natural feel for a soft brand image. |

You can choose the label style that fits your brand. You can also pick special packaging or add embroidery. These choices help your products stand out, even with ready-made designs.

Customer Perception

How you make your clothes changes how customers see your brand. Custom clothing shows you care about quality and style. Customers like brands that let them choose what they want. They feel special when they get something made just for them.

Private label clothing also helps your brand look good. Many people think private label products are special and worth more. You can use what customers say to change your products. This helps you give shoppers what they want and keeps them coming back.

Custom clothing makes customers happy with special choices.

Private label brands can keep customers by offering exclusive items.

Both ways help you build a brand people trust and remember.

Tip: Think about what your customers want most. Pick the way to make clothes that helps you meet their needs and build a strong brand.

Quality & Oversight

Quality Control in Custom Clothing Manufacturing

You want your knitted garments to be high quality. Custom clothing lets you set your own rules for checking quality. You can look at every step, from fabric to finished clothes. Most custom makers use tests and checks to make sure things are right.

Here is a table that shows common ways to check quality in custom clothing:

Quality Control Process | Description |

|---|---|

Fabric Quality | Tested to see if colors stay bright and do not fade. |

Stitching Quality | Checked for strong seams and tight stitches. |

Garment Measurements | Measured often to keep sizes the same and stop shrinking. |

Adherence to Standards | Follows safety and quality rules like ISO, AATCC, and CPSIA. |

You can also look at the fabric’s color, weight, width, and length. These checks help you find problems early and fix them before making all the clothes.

Private Label Manufacturing Standards

Private label makers use set rules to keep things the same. You get clothes that meet the same standards each time. These makers follow strict steps for checking quality. This helps you trust that every batch will look and feel the same.

Private label makers use strong quality checks.

You get products that are always high quality.

Makers work with you to make sure the clothes fit your brand.

Private label clothes are made for your brand. You can ask for special features or changes. You get some control over fabric and fit. You also get help from the maker’s experience and systems.

Managing Production Risks

You face risks with both custom and private label clothes. Mistakes can happen at any step. You might get the wrong color, size, or weak stitching. You can lower these risks by working closely with your maker.

Here are some ways to lower risks:

Ask for samples before making all the clothes.

Check quality at every step, not just at the end.

Use clear contracts that list your rules.

Talk often with your maker.

Tip: Good planning and regular checks help you avoid mistakes and keep your brand strong.

You can build trust with your maker by staying involved. This helps you catch problems early and give your customers high-quality knitted garments.

Best Fit Scenarios

When to Choose Custom Clothing Manufacturers

Pick custom clothing manufacturers if you want full control. You can design every part, from yarn to stitches. This helps you make items that match your brand. Custom clothing is good for special or limited edition products. You set your own rules for quality and style.

Many businesses like custom clothing manufacturing. You might run a print-on-demand shop. Dropshipping brands use it to avoid keeping stock. Made-to-order shops offer unique items without storing them. Resale businesses can use custom clothing, but need more money at first.

Print-on-demand stores

Dropshipping brands

Made-to-order shops

Resale businesses

Custom clothing is great for athleisure wear, like yoga pants. It also works for sports bras and graphic tees. You can sell embroidered jackets too. These products often make more money and help you stand out.

When to Choose Private Label Clothing

Choose private label clothing if you want to launch fast. You save money and pick from ready-made styles. Add your branding to these clothes. Start with small orders and test the market. This is good for new brands that want to grow quickly.

Private label manufacturing gives you flexibility. You can change colors, trims, or packaging. This helps you follow trends and meet customer needs. You do not design every part, so you save time and effort.

Private label is smart for brands that want to:

Enter the market quickly

Test new styles with low risk

Scale up production as demand grows

Many top knitted garments manufacturers offer private label services. You can find partners who help you make custom knitted garments with less work.

Example Scenarios

You may wonder how these choices work in real life. Here are some examples to help you decide:

Scenario | Best Option | Why It Works |

|---|---|---|

Launching a yoga wear brand | Custom clothing | Full control over design and quality |

Starting a baby clothing line | Private label | Small batch production and quick market entry |

Selling graphic tees online | Custom clothing | Unique designs and higher profit margins |

Expanding an organic kidswear shop | Private label | Flexible orders and easy scaling |

Medical textile business | Specialized garments for healthcare needs |

Tytex shows how custom clothing helps in the medical field. They make seamless knitted wear for healthcare. Custom designs help with support and compression garments. Small batch manufacturing helps brands in baby, kids, and organic clothing. You can offer custom designs and stay flexible.

Private label manufacturing works for brands that want to grow fast. You can use private label to test new products and change quickly. Many knitted garments manufacturers support private labeling. This makes it easy to find the right partner.

Tip: Think about your business goals and budget. Decide how much control you want. Pick the option that fits your needs and helps your brand do well.

Decision Guide

Assessing Business Goals

You need to start by looking at your business goals. Think about what you want to achieve with your knitted garments brand. Do you want to build a brand that stands out with unique designs? Custom clothing manufacturing helps you create products that match your vision. You can control every detail and make your brand special.

If you want to launch quickly and test the market, private label gives you speed and flexibility. You can pick from ready-made styles and add your branding. Private label works well if you want to grow fast or offer many products. You do not need to spend time on design or wait for long production times.

Ask yourself these questions:

Do you want full control over design and quality?

Are you aiming for a unique brand image?

Do you need to launch products quickly?

Is your goal to scale up and reach more customers fast?

Tip: Write down your top three business goals. Match them with the strengths of custom clothing or private label to see which fits best.

Budget & Resource Evaluation

You need to check your budget and resources before you choose a manufacturer. Custom clothing often costs more because you pay for design, samples, and special materials. You need to plan for higher upfront costs. Custom clothing manufacturers may ask for larger orders, which means you spend more at the start.

Private label manufacturing lets you start with less money. You can order smaller batches and avoid big design fees. Private label helps you save money and lower your risk. You can use wholesale and oem pricing to get better deals when you order more.

Here is a table to help you compare costs:

Option | Upfront Costs | Minimum Orders | Risk Level | Best For |

|---|---|---|---|---|

Custom Clothing | High | Larger | Higher | Unique, high-end brands |

Private Label | Low | Smaller | Lower | Fast launches, scaling |

Note: Always ask for a full cost breakdown. Include hidden costs like sampling, packaging, and quality control.

Brand Vision & Timeline

Your brand vision shapes your choice. If you want a brand known for special designs and high quality, custom clothing is the way to go. You can create garments that tell your story and attract loyal customers. Custom manufacturing lets you set your own standards and build a strong identity.

If your vision is to offer trendy styles and respond to market changes, private label works better. You can launch new products quickly and keep up with fashion trends. Private labeling helps you stay flexible and meet customer needs fast.

Think about your timeline. Custom clothing takes longer because you design from scratch. You need to wait for samples and production. Private label lets you launch products in less time. You can test new ideas and restock quickly.

Ask yourself:

Do you want to build a brand with unique products?

Is speed more important than full control?

How soon do you need to launch your garments?

Block Quote: Your brand vision and timeline guide your choice. Pick the option that matches your goals and helps you grow.

Manufacturer Selection Checklist

You need to pick the best knitted garments manufacturer for your business. Use this checklist to help you compare custom clothing and private label choices. It will help you make a smart decision and avoid problems.

Factor | Description |

|---|---|

Lead Times | Check how long sampling, making, and shipping take. Make sure you can launch on time. |

Manufacturing Capabilities | Ask if the factory can make the styles you want. Make sure they know knitwear and your customization level. |

Certifications and Compliance | Look for factories with certifications. These show they follow good and green practices. |

Sampling Process and Flexibility | Find out how many samples you can get. Ask if you can change things during the process. |

Pricing and Payment Terms | Ask for a full cost list. Know the payment rules so you do not get surprise fees. This matters for both custom clothing and private label. |

Factory Reputation and Experience | Read reviews and ask for references. Pick a factory with happy customers and a good history. |

Location and Shipping Logistics | Think about where the factory is. Location changes cost, speed, and how easy it is to talk to them. |

Tip: Use this checklist when you talk to manufacturers. It helps you compare custom clothing and private label choices side by side.

Here is a simple list to help you:

Lead times: Will you get your products on time?

Manufacturing capabilities: Can the factory make your designs?

Certifications and compliance: Do they follow safe and fair rules?

Sampling process and flexibility: Can you see samples and ask for changes?

Pricing and payment terms: Do you know all costs, including wholesale and oem pricing?

Factory reputation and experience: Do other brands trust this factory?

Location and shipping logistics: Will shipping be quick and not cost too much?

You should also ask about quality control. Good factories check every step to make sure your knitted garments look and feel great. This is important for both custom clothing and private label.

When you use this checklist, you can feel sure. You will know you picked the best manufacturer for your brand.

Getting Started

Questions for Knitted Garments Manufacturers

You need to ask the right questions before you choose a knitted garments manufacturer. Good questions help you understand what the manufacturer can do for your brand. You learn about their experience, production process, and quality standards. Here are some questions you should ask:

What types of knitted garments do you specialize in?

Can you show samples of your previous work?

What is your minimum order quantity for each style?

How long does production usually take?

What certifications do you hold for quality and safety?

Do you offer custom design services or only private label options?

How do you handle quality control during production?

What are your payment terms and pricing structure?

Can you help with packaging and branding?

Where is your factory located, and how do you ship products?

Tip: Write down your questions before you contact manufacturers. This helps you compare their answers and choose the best partner for your business.

Preparing for Production

You need to prepare before you start working with a manufacturer. Planning helps you avoid mistakes and keeps your project on track. Here is a step-by-step guide to help you get ready:

Decide what product you want to make. Pick styles and features that fit your brand.

Set your budget. Know how much you can spend on design, production, and shipping.

Make a list of machinery you need, based on your product and budget.

List potential customers and start reaching out to them.

Choose your target market. Decide if you want to sell directly or use job working.

Plan your production based on your sales goals and budget.

Pick the right location for your unit. Areas with other garment factories make staffing easier.

Start setting up your unit. This may take two to three months. Hire at least one experienced staff member to manage workers.

Note: Careful planning helps you launch your knitted garments brand smoothly. You save time and money when you prepare well.

Common Pitfalls

You may face challenges when you work with custom or private label manufacturers. Knowing these pitfalls helps you avoid problems and build a strong business. Here are some common mistakes:

Underestimating data quality. You need clean and accurate data for good decisions. Bad data can lead to wrong choices.

Overlooking data privacy. Protect sensitive information to avoid legal trouble.

Neglecting to stay updated on new technology. AI and other tools change fast. If you ignore updates, you miss chances to improve your business.

Ignoring unexpected challenges. New systems and processes can bring surprises. Plan for problems so you can solve them quickly.

Block Quote: Stay alert and plan for challenges. This helps you keep your knitted garments business running smoothly and protects your brand.

You can avoid most problems by asking questions, planning well, and staying informed. This gives you the best chance for success when you start working with a knitted garments manufacturer.

You have learned how custom clothing and private label are different. Custom clothing lets you control every part and make your brand special. Private label helps you start fast and try new ideas. Think about what you want and what you have before you pick a knitted garments manufacturer. Use a checklist or ask experts if you need help. You can choose what is best for your business.

FAQ

What is the main difference between custom and private label manufacturing?

You design every detail with custom manufacturing. Private label lets you choose from existing styles and add your branding. Custom gives you more control. Private label helps you launch faster.

How do I know which option fits my brand?

Write down your goals. If you want unique designs, choose custom. If you want to test products or scale quickly, pick private label. Match your choice to your budget and timeline.

What is MOQ and why does it matter?

MOQ means Minimum Order Quantity. It tells you the smallest number of items you must order. Custom usually has higher MOQs. Private label lets you start with smaller orders.

Can I change designs after production starts?

You can make changes with custom manufacturing before production begins. After production starts, changes cost more. Private label offers less flexibility. You pick from set designs, so changes are limited.

How long does it take to get my products?

Custom clothing takes two to four weeks or more. Private label is faster because designs are ready. You can often get products in less time.

Is private label clothing lower quality than custom?

No. Many private label products use high-quality materials and strict checks. You can ask for samples to check quality before you order.

What should I ask a knitted garments manufacturer before I order?

What is your MOQ?

How long does production take?

Can I see samples?

What are your payment terms?

Do you offer both custom and private label options?

Tip: Always ask for a full cost breakdown before you decide.