You will see new ideas and careful work in today’s knitwear. Merino wool is soft and strong. This makes clothes comfy and long-lasting. Factories use new machines to make great knitwear. New changes have improved how things are made:

Seamless knitting technology helps save materials and makes clothes feel better.

Circular seamless knitting machines make special textures and designs.

Working with The Woolmark Company helps make strong and useful clothes.

A fine gauge merino knitwear factory uses old and new ways to make great products.

Key Takeaways

Modern factories use special machines to make merino knitwear fast and well. These machines help workers do their jobs better. Seamless knitting technology helps make less waste. It also makes clothes more comfortable by removing seams. Factories pick merino wool carefully to get the best fibers. This makes the knitwear soft and strong. Ethical shearing helps keep animals safe and healthy. It also helps make better wool. Quality control is important at every step. Workers check the yarn and the finished clothes. This makes sure the products are always good. Advanced spinning methods, like ring spinning, make yarn softer and finer. This is great for making fancy knitwear. Different factories work together and share jobs. This helps make the final product even better. Finishing steps, like washing and dyeing, make the knitwear softer. They also make the colors look brighter and nicer for buyers.

Sourcing Merino Wool

Modern factories pick wool carefully to make fine merino knitwear. They start with the best wool. Every step is important for good quality.

Selecting Premium Fleece

Factories choose fleece that meets high standards. They look for luxury fibers that feel soft and are strong. The main places for merino wool are East Asia, South Asia Oceania, and Europe. These regions give a lot of wool to the world.

Region | Market Share (%) | |

|---|---|---|

East Asia | 367.5K | 30 |

South Asia Oceania | N/A | 23 |

Europe | N/A | 25 |

When picking fleece, factories check many things.

Criteria | Description |

|---|---|

Micron Count | Lower counts mean finer fibers. Finer fibers feel softer. |

Fiber Content | Mixing fibers can make knitwear stronger and better. |

Softness | Finer fibers feel softer and less itchy on skin. |

Durability | Blends help knitwear last longer. |

Care Requirements | Superwash treatment changes how you care for yarn. |

Lower micron counts make fibers softer.

Softer fibers are best for wearing next to skin.

Higher micron counts make wool rougher and itchier.

Fine merino fleece is known for being soft and comfy. Factories use merino blends to make clothes stronger and last longer.

Ethical Shearing

Factories want wool from farms that treat sheep well. Skilled workers shear sheep gently. This keeps sheep healthy and calm. Factories work with farms that follow animal care rules. Buying knitwear made from ethical wool helps support good farming.

Transport To Factory

After shearing, wool goes from farms to factories. Many transport methods are used. Trucks take wool bales from farms to auction centers. Ships move wool across oceans, mostly from Australia to China. Trucks in China bring wool to mills.

Description | |

|---|---|

Road Transport | Trucks move greasy wool bales (178 kg) from farms to auction. |

Transoceanic Freight | Ships carry wool from Australia to China on trade routes. |

Road Transportation in China | Trucks move greasy wool (30-ton load) from port in China to mills. |

The time it takes depends on distance and route. Careful handling keeps wool safe and good. This makes sure fine merino fleece gets to the factory ready for the next step.

Wool Preparation

Before you can turn raw fleece into beautiful knitwear, you need to prepare the wool. This stage makes sure the fibers are clean, smooth, and ready for spinning into high-quality yarn.

Scouring And Cleaning

You start by washing the raw wool. This step is called scouring. It removes dirt, grease, and sweat from the fleece. Factories use large tanks filled with warm water and gentle soap. Machines move the wool through several baths. Each bath gets rid of more impurities. Clean wool feels soft and looks bright. If you skip this step, the final yarn will not be smooth or strong.

Tip: Clean wool helps you make better yarn. Dirt or grease can cause problems in later steps.

Carding And Combing

After cleaning, you need to separate and straighten the fibers. Carding machines use rollers covered with tiny wire teeth. These teeth pull the fibers apart and line them up. Carding also removes small bits of dirt that scouring missed.

Next, you use combing machines. Combing takes out short fibers and tiny knots called neps. This step leaves you with long, smooth fibers. These fibers make the yarn stronger and more even. Factories use both carding and combing to get the best results.

Here is a table that shows how each process helps:

Process | Description |

|---|---|

Carding | Cleans and aligns fibers, preparing them for further refinement. |

Combing | Removes short fibers, neps, and impurities, resulting in smoother and stronger yarns. |

Final Quality | Produces high-quality combed slivers with a higher proportion of long fibers, enhancing yarn uniformity. |

When you use both carding and combing, you get fibers that are ready for top-quality yarn.

Fiber Alignment

You want all the fibers to point in the same direction before spinning. Carding helps with this by making a soft, flat sheet called a web. Modern carding machines use spinning drums with fine wires. These wires separate and align the fibers. The result is a smooth, even web that you can turn into a sliver.

Combing comes next. This step lines up the long fibers even more. It removes any short pieces left after carding. The fibers now lie side by side, ready for spinning. This careful alignment is important for making strong, smooth yarn. When you spin the fibers, they twist together evenly. This gives you a yarn that feels soft and lasts a long time.

You can see that each step in wool preparation helps you make better yarn. Clean, aligned fibers are the secret to fine merino knitwear.

Spinning Fine Yarn

When you want to make fine gauge merino knitwear, you need to spin the fibers into high-quality yarn. This step is important because the yarn decides how your knitting will look and feel. You will see how factories use advanced spinning methods to get the best results.

Advanced Spinning Methods

Factories use two main spinning methods for fine yarn. Each method has its own strengths. You should know how they work before you choose the right one for your knitting process.

Open-end spinning (also called rotor spinning) works very fast. This method uses a spinning rotor to twist the fibers into yarn. You get a lot of yarn quickly. However, this method makes rougher yarn. It works best for heavy fabrics, not for soft knitwear.

Ring spinning is the traditional way to make fine yarn. You start by carding and drafting the fibers. Then, you twist them into smooth, even yarn. This method takes more time and uses more steps. You get a finer, softer, and more uniform yarn. Most factories use ring spinning for merino knitwear because it gives you the best quality for knitting.

You can see that ring spinning is slower, but it makes yarn that feels soft and looks smooth. This is important for fine gauge knitting. Open-end spinning is faster, but you lose some softness and quality.

Consistent Yarn Quality

You want every piece of yarn to be strong and even. Factories use special tests to check the yarn during spinning. These tests help you make sure the yarn will work well for knitting and last a long time in knitted fabrics.

Purpose | |

|---|---|

Twist Testing | Measures the number of turns per unit length to determine yarn strength and appearance. |

Tensile Testing | Evaluates the strength of the yarn to ensure it meets the demands of its intended use. |

Yarn Count Testing | Assesses the linear density of yarn to maintain consistent thickness and quality. |

You will see workers check the twist of the yarn. This test tells you if the yarn will hold together during knitting. Tensile testing checks how much force the yarn can take before it breaks. Yarn count testing makes sure every batch has the same thickness. These tests help you avoid weak spots or uneven yarns.

Tip: Consistent yarn quality means your knitting machines can run smoothly. You get fewer breaks and better-looking knitwear.

When you use these advanced spinning methods and quality checks, you make sure your merino yarn is ready for the next step. The right yarn helps you create soft, strong, and beautiful knitwear. You can trust that your knitting will turn out well when you start with high-quality yarn.

Fine Gauge Merino Knitwear Factory Technology

Computerized Knitting Machines

Factories use advanced knitting machines to make smooth fabrics. These machines have many needles, between 24 and 30 gauge. This helps make fabric that feels soft and looks nice. Computerized knitting machines let you control every part of knitting. You can set the speed, pattern, and tension very exactly.

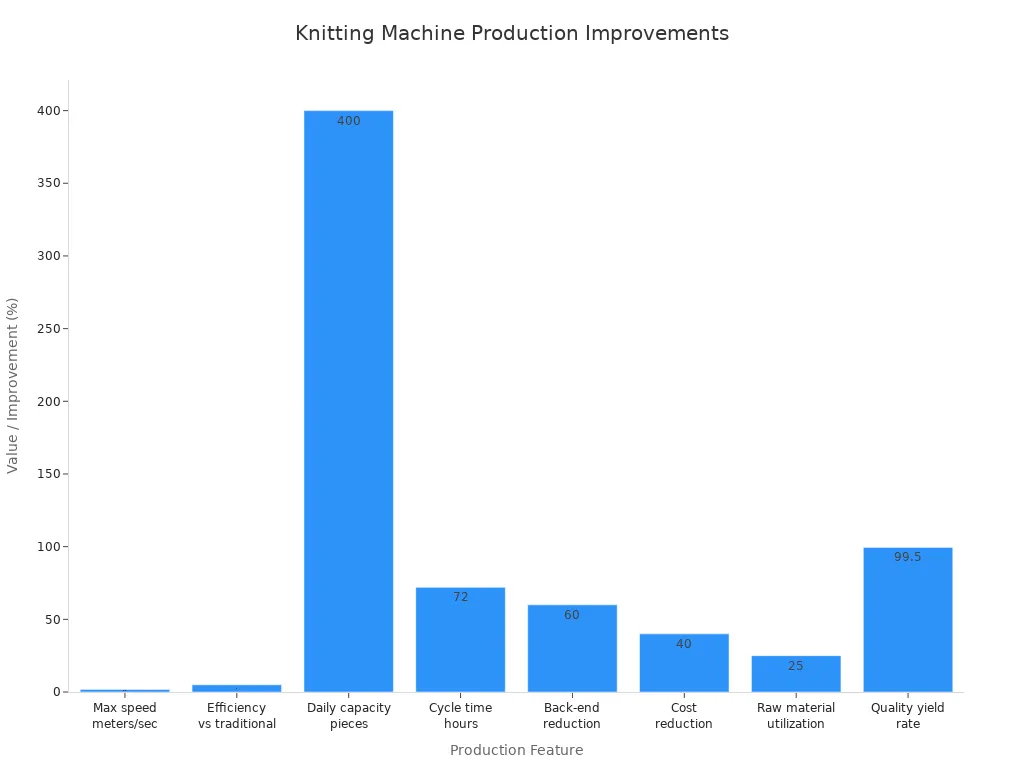

Modern factories use these machines to work faster and better. They can make up to 1.8 meters of fabric each second. This is much faster than old machines. One factory can make 300 to 500 sweaters in a day. Production time is much shorter now. It used to take 15 days, but now it takes only 72 hours. The machines cut down extra steps by 60%. This saves time and money. Digital systems help you watch every part of the process. Smart yarn break detection lets you use 25% more raw materials. AI checks the quality, so you get a yield rate over 99.5%.

Here is a table that shows how these machines help:

Feature | Benefit |

|---|---|

Production speed | Maximum speed of 1.8 meters per second |

Production efficiency | 5 times higher than traditional equipment |

Daily production capacity | 300-500 pieces (standard sweaters) |

Reduction in production cycle | Shortened from 15 days to 72 hours |

Reduction in back-end processes | 60% reduction |

Cost reduction | Comprehensive production costs reduced by 40% |

Digital process management | Achieved 100% digital process management |

Yarn break detection | Intelligent system increases raw material utilization by 25% |

Quality yield rate | AI quality inspection system yield rate >99.5% |

These machines help you make fine gauge merino knitwear faster and better. You also waste less material.

Programming For Panel Production

In a fine gauge merino knitwear factory, you must program machines for each design. You use special software to make patterns and set up knitting. This step is important for making panels that fit together well.

You can follow these steps for good results:

Learn the design and programming software. This helps you control every part of knitting.

Use shortened knitting methods. These save yarn and cut down on cutting and sewing.

Make your patterns better. Good programming makes knitting faster and easier.

Test your design before knitting. The software lets you check for mistakes before you start.

These programming steps help your panels turn out right every time. You waste less yarn and save time.

High Gauge Precision

High gauge precision helps you make knitwear that feels soft and looks smooth. High gauge means more needles per inch. This lets you make thin, light fabrics with tight texture. You can see every detail in the pattern. The fabric feels gentle on your skin.

Flatbed knitting machines help you get this precision. You can change tension and speed for each yarn type. This gives you control over fabric thickness and strength. Modern factories use high gauge precision to meet top standards. You can make sweaters, shirts, and other clothes that look and feel fancy.

Tip: Always check your yarn and machine settings before knitting. This helps you avoid mistakes and keeps your fabric even.

High gauge precision helps you make fine gauge merino knitwear that is high quality and comfortable.

Collaboration Between Factories

You may think one factory makes your fine gauge merino knitwear. But many factories work together to make each piece. This teamwork gives you better quality and more options.

Factories do different jobs. One factory spins the yarn. Another factory knits the panels. A third factory does finishing like washing or dyeing. Each factory has its own machines and skilled workers. When factories share their skills, you get knitwear that feels soft and lasts longer.

Factories usually work together like this:

Yarn Spinning Mill

The mill spins merino wool into fine yarn. Workers check the yarn for strength and smoothness.Knitting Factory

The yarn goes to a knitting factory. Workers use computerized machines to knit panels or seamless garments. The factory programs each design for accuracy.Dyeing and Finishing Plant

After knitting, the panels go to a dyeing and finishing plant. This plant washes, softens, and colors the fabric. Special machines help keep the fabric soft and bright.Assembly Workshop

The last step is in an assembly workshop. Workers cut, sew, and link the panels. They check each piece for quality before packing.

Note: When factories work together, you get faster production and better quality. Each factory does what it is best at.

Here is a table that shows how each factory helps:

Factory Type | Main Task | Key Benefit |

|---|---|---|

Yarn Spinning Mill | Spinning and testing yarn | Strong, even yarn |

Knitting Factory | Knitting panels | Accurate shapes and sizes |

Dyeing/Finishing Plant | Washing and coloring | Soft, bright fabric |

Assembly Workshop | Sewing and linking | Neat seams and fit |

Teamwork between factories helps you get the best knitwear. Each step uses special skills and machines. This way, you get clothes that look and feel great.

Panel Cutting And Assembly

When you reach the panel cutting and assembly stage, you start to see your fine gauge merino knitwear take shape. This part of the process decides how your garment will fit and feel. You use special tools and machines to cut, sew, and finish each piece. You want every step to be precise so your knitwear looks and feels great.

Cutting Knit Panels

You begin by cutting the knit panels. Factories use different technologies for this step. Each method affects how much material you waste. You want to choose the right one to save resources and get the best results.

Here is a table that shows how different knitting technologies impact waste:

Knitting Technology | Waste Reduction | Description |

|---|---|---|

3D-Knitting | Less than 1% | Produces garments as one continuous knit, eliminating panels and seams. |

Cut-and-Sew | 20% | Involves cutting large fabric panels and sewing them together, resulting in higher waste. |

Circular Knitting | Moderate | Creates tubular fabric, reducing side seams but still requires some cutting and sewing. |

2D-Knitting | Lower than cut-and-sew | Produces pre-shaped panels but still requires sewing, leading to some waste. |

You can see that 3D-knitting creates almost no waste. Cut-and-sew methods waste more material. When you use rotary cutters, you get better precision. This helps you cut panels that match your pattern and reduce mistakes.

Tip: Always check the stretch knit gauge on your pattern. This helps you cut panels that fit together well.

Sewing And Linking

After you cut the panels, you need to join them. You use sewing and linking techniques to make strong seams. You want your knitwear to last and stretch without breaking.

Use a rotary cutter for clean edges.

Add interfacing to stabilize details and keep the fabric stretchy.

Pay attention to the stretch knit gauge for the best fit.

Using a linker makes it a lot quicker. Linkers make a chain stitch, which is extensible so will not burst the seam when the fabric is stretched. The tension of the chain stitch can be adjusted with a thumb screw, and it is important to use this adjustment to achieve successful linking.

You can see that linkers help you make seams that stretch and stay strong. This is important for fine gauge merino knitwear.

Seamless Finish

You want your knitwear to feel smooth and comfortable. Seamless technology helps you reach this goal. Advanced machines, like those from Santoni, let you knit garments without seams.

“Seamless technology from Santoni Shanghai is key to creating graphics within the textiles,” explains Santoni Shanghai Marketing Director Leila Guo. “When seams are removed, fantastic results can be achieved; the garment attains a new level of comfort that is seldom found with conventional methods.”

Advanced seamless technology is used.

Circular knitting machines from Santoni create garments without seams.

Superfine 15.5 micron Merino wool yarn makes the fabric soft and high-performing.

When you use seamless technology, you get knitwear that feels gentle on your skin. You also see better fit and fewer weak spots. This step helps you make luxury garments that stand out.

Finishing Touches

Washing And Softening

You want your merino knitwear to feel soft. Factories wash and soften each garment. This makes the fabric gentle on your skin. You can clean and soften merino wool by following these steps: Fill a basin with warm water. Add a gentle detergent made for wool. Put the garment in the water and let it soak for 10-15 minutes. Rinse it with clean warm water. Press out extra water, but do not twist the fabric.

After washing, you can use softeners to make the fabric feel better. Wool conditioners add moisture and help the wool stay soft. Vinegar and baking soda are natural softeners. They make the fibers smoother. Some factories use fabric conditioners from stores. These help reduce static and coat the fibers.

Tip: Always use gentle products. Do not use strong chemicals. This keeps your knitwear soft and strong.

Softener Type | Effect on Merino Wool |

|---|---|

Wool Conditioner | Adds moisture, improves softness |

Vinegar/Baking Soda | Natural softness, gentle finish |

Fabric Conditioner | Reduces static, coats fibers |

Blocking And Shaping

You want your knitwear to look neat and fit well. Blocking and shaping help you get the right size and shape. This step relaxes the fibers and sets the final form. You can follow these steps: Soak your knitting to relax the fibers. Roll it in a towel to remove extra water. Do not twist the fabric. Pin the knit to a board and shape it. Let it dry before you take out the pins.

Blocking helps smooth out wrinkles and set the edges. You can shape sleeves, necklines, and hems. This makes your knitwear look tidy and ready to wear.

Note: Blocking is important for fine gauge knitwear. It helps you get a good fit and a neat look.

Dyeing And Color Quality

You want your knitwear to have bright colors that last. Factories use top-dyed yarn to make colors strong and even. This means the yarn is dyed before knitting. The color stays bright and does not fade easily.

Factories test color quality in many ways. Each test checks if the color will last:

Color Quality Test | Purpose |

|---|---|

Checks if color stays after washing | |

Colourfastness to Light | Tests resistance to sunlight |

Colourfastness to Perspiration | Measures color stability with sweat |

Colourfastness to Water/Seawater/Chlorine | Ensures color holds in different waters |

Colourfastness to Dry Cleaning/Bleaching | Checks for fading during cleaning |

Colourfastness to Saliva | Tests safety for children’s wear |

You can pick good dyes to keep colors bright. Factories use hue fixatives to help dyes stick to the fibers. Regular tests make sure every batch meets the standards.

Tip: Wash and store your knitwear the right way. This keeps colors bright and the fabric strong.

Finishing steps like washing, blocking, and dyeing help you enjoy merino knitwear that feels soft, fits well, and looks bright.

Quality Control In Factories

Inspection At Each Stage

You want every piece of fine gauge merino knitwear to meet high standards. Factories check quality at each step. This helps you catch problems early and keep the final product consistent.

You can see these inspection steps in a modern factory:

Yarn Lot Testing: You test each batch of yarn before knitting. This makes sure the yarn is strong and even.

Panel Inspection: You check the size and stitches of each knit panel. This step helps you spot mistakes before sewing.

Finishing QA: After washing and steaming, you inspect the garment again. You look for color, softness, and shape.

Harvesting Quality Control: You make sure shearing is gentle and the wool is clean.

Skirting and Sorting: You remove dirt and sort wool by quality. This keeps only the best fibers for your knitwear.

Factories also follow a careful order for inspections:

Knitting Tension Monitoring

Panel Inspection & Measurement

Linking & Seaming QC

Finishing QC (post-wash/post-steam)

Inline Measurement Calibration

Final AQL Inspection (Pre-Shipment)

Tip: Checking at every stage helps you avoid big problems later. You save time and materials by fixing small issues early.

Durability Testing

You want your knitwear to last. Factories use special tests to check how strong and durable each piece is. These tests follow industry rules and help you trust the quality.

Here is a table that shows common durability tests and what they measure:

Test Type | Description/Benchmarks |

|---|---|

Pilling | You test for fuzz balls using IWS pilling tests (ISO 12945). |

Shrinkage Control | You check if the garment shrinks. Good results are 5–12% in length and 4–10% in width. |

Factory Solutions | You use Superwash treatment and wash below 30°C to keep shape and size. |

You can see that these tests help you know if your knitwear will stay soft and look good after many washes.

If you want your merino knitwear to last, always follow the care instructions. This keeps the fabric strong and smooth.

Consistency And Traceability

You want to know where your knitwear comes from. Many brands now track every step, from sheep to store. This gives you confidence in what you buy.

ASKET, a Swedish menswear brand, traces its collection back to the source of the wool. You can see where the wool comes from and how it is made.

The brand documents each part of the process. They reach 80% traceability for their garments.

The Woolmark Company helps designers build strong supply chains. They support transparency through programs like the International Woolmark Prize.

When you choose knitwear with good traceability, you support fair and open production. You help make the fashion industry better for everyone.

You can trust that modern factories use technology and teamwork to keep quality high. Each step, from inspection to traceability, helps you get knitwear that feels great and lasts a long time.

You notice luxury in each piece when you look at every step. The process starts with shearing and ends with inspection. Factories use high-quality yarn and seamless construction. Workers pay close attention to every detail. This makes fine layering pieces that last a long time. Advanced machines and teamwork help factories make better products. These changes help factories work smarter and waste less. The knitwear industry now cares about the planet and real craftsmanship.

When you learn how a modern garment is made, you see the care and value in each piece.

Consumer Trend | Description |

|---|---|

Market Growth | More people want knitwear that is high quality and good for the planet. |

Careful work creates luxury.

Modern methods help every garment reach high standards.

Smart production helps the planet and makes clothes last.

FAQ

What does “fine gauge” mean in merino knitwear?

You see “fine gauge” when the fabric uses many needles per inch. This creates a thin, smooth, and lightweight knit. Fine gauge knitwear feels soft and looks elegant.

How do factories keep merino wool soft?

You get soft merino wool because factories use gentle washing, careful spinning, and special softeners. These steps protect the fibers and keep the natural softness.

Is merino knitwear itchy?

You will not feel itchiness with fine gauge merino. The fibers are very thin and smooth. This makes the fabric comfortable against your skin.

How do factories ensure ethical wool sourcing?

You can trust ethical factories. They work with farms that follow animal welfare standards. They use gentle shearing and trace the wool back to the source.

Can you wash merino knitwear at home?

You can wash merino knitwear by hand or use a gentle machine cycle. Always use cool water and mild detergent. Lay the garment flat to dry.

Why do factories use seamless knitting machines?

You get seamless knitwear for better comfort and less waste. Seamless machines knit garments in one piece. This means fewer seams and a smoother fit.

How do you know your knitwear is high quality?

You can check for even stitches, soft feel, and strong seams. High-quality knitwear also comes with care labels and sometimes traceability information.