When you want the right manchester knitwear manufacturer for your brand, focus on what matters most. Look at production quality and make sure the price fits your budget. Check if the team delivers on time and stands by their promises. Define your knitwear needs with clear details and use digital tools for better accuracy. Build a strong partnership to get the best results every season.

Key Takeaways

Make sure you know what your brand needs. This helps you find a manufacturer that matches your ideas.

Think about who will buy your products. Pick styles and order sizes that your customers want.

Check how well the products are made. Look for strong stitches and colors that do not fade. Make sure they follow your rules.

Find manufacturers who let you order small amounts. This helps you try new designs without spending too much money.

See if the manufacturer is dependable. Look at how they deliver and how fast they answer messages.

Use technology in your knitwear designs. This makes them more exact and helps save materials. It is better for the environment.

Go to the factories to see how people work there. Meet the team and check if they meet your standards.

Make good relationships with your manufacturers. Use clear contracts and talk openly. This helps you work together for a long time.

Define Your Brand’s Knitwear Needs

Before you look for a Manchester knitwear manufacturer, think about your brand. Decide what your brand means and what you want to make. This helps you find a partner who understands your ideas. It also helps you reach your goals for growth and sustainability.

Market Segment for Startup Fashion Brand

Think about who will buy your products. Are you making clothes for young adults, kids, or luxury buyers? Knowing your market helps you make good choices. If you have a startup fashion brand, you may want to try new styles in small batches. Some Manchester manufacturers, like Muff Garments, let you order as few as 12 pieces. This helps you test new ideas without spending too much money. Others, like Britton International Ltd., let you change your order size. This is helpful if you want custom designs or need to change quickly.

Product Specifications

Be clear about what kind of knitwear you want. This helps you find a manufacturer who can meet your needs. It also helps you stick to your sustainability goals.

Fabric Type and Weight

Choose the fabric you want. Do you want cotton, wool, or eco-friendly materials? The weight of the fabric is important too. Lighter knits are good for spring. Heavier knits are better for winter. Some Manchester manufacturers are experts in cotton knit fabrics. If you care about sustainability, ask about recycled yarns and eco-friendly production.

Color and Size Range

Pick your colors and sizes. Do you want classic colors or bright ones? Will you offer many sizes? Clear choices help your manufacturer plan and avoid mistakes. Ask if they use digital tools to match colors and sizes. This makes things more accurate and helps reduce waste.

Special Features

Think about any special details you want. Maybe you want embroidery, special trims, or custom labels. Write down these features so your manufacturer knows what you expect.

Order Volume and Frequency

Plan how many pieces you want to order and how often. This affects your costs, inventory, and cash flow. Here is a table showing common knitwear order minimums in Manchester:

Category | Minimum | Notes |

|---|---|---|

Knitwear | 200 units | Single colorway |

Some suppliers let you order as few as 12 pieces. This is good for testing new ideas. Others let you change your order size as your brand grows.

Tip: Lower minimum order quantities help you try new designs and change with the market. High minimums can leave you with extra stock and use up your money.

Here are things to think about when planning your order volume:

Factor | Implication |

|---|---|

Minimum Order Quantities | High MOQs can lead to money problems and too much stock. |

Financial Risks | Unsold products can use up your money and stop you from trying new ideas. |

Inventory Management | High MOQs can mean too much stock, which costs more to store. |

Supplier Flexibility | Lower MOQs let you test new designs and change with the market without big risks. |

When you know your knitwear needs, you can work better with your manufacturer. You also make it easier to follow your values, like using eco-friendly materials, from the start.

Evaluating Manchester Knitwear Manufacturer

Production Quality

When you pick a Manchester knitwear manufacturer, check their production quality first. You want your knitwear to look nice and last long. Good quality means strong stitches and smooth finishes. Colors should stay bright after washing. Many manufacturers in Manchester follow strict rules to meet your needs.

Here are some ways they keep quality high:

Use the same yarn lot and machine settings for each batch.

Check every item with your tech pack and color samples.

Different teams do technical reviews before making size sets.

Get all approvals before starting production.

Test fit on mannequins to make sure sizing is correct.

Change things based on fit tests and tech pack rules.

Inspect knitted panels on the machine to catch problems early.

Do visual checks and watch tension in real time.

Look at finished panels under bright lights to find hidden flaws.

Review hand-hemmed edges for neatness and evenness.

Test colorfastness using ISO 6330 wash rules.

Compare garment sizes to the approved spec sheet.

Audit batches using 2.5 AQL standards.

Manchester knitwear manufacturers use quality assurance to keep products the same. Here’s a quick look at what you might see:

Description | |

|---|---|

ISO 9001 | Shows strong internal quality management. |

BSCI or Sedex | Proves ethical labor and factory audits. |

AQL 2.5 inspection reports | Checks for low defect rates in random batches. |

Fabric weight | 180–200 GSM for standard jerseys. |

Stitch density | At least 8 stitches per centimeter for durability. |

Colorfastness | Stays bright after washing and sun exposure. |

If you care about sustainability, ask your knitwear manufacturer about eco-friendly yarns and production methods. Many clothing manufacturers in Manchester now offer recycled materials and energy-saving steps. This helps you reach your sustainability goals and gives your brand a good image.

Cost-Effectiveness

You want great knitwear, but you also need to save money. Cost-effectiveness means getting good value for your money. Manchester knitwear manufacturers have smart ways to help you spend less.

Here are some tips to lower your costs:

Sample many colors at once for group discounts.

Give detailed tech packs to avoid extra sampling rounds.

Use a clothing fit reference to get the right fit first.

Make your garment design simple to cut down on costs.

When you work with a knitwear manufacturer, ask about their prices for small batches and big orders. Some offer flexible minimums, so you can test new styles without spending too much. If you focus on sustainability, you might save money by using recycled yarns or simple production steps.

Reliability and Track Record

Reliability is important when you choose a Manchester knitwear manufacturer. You want a partner who delivers on time and keeps promises. A good track record means fewer problems and better results for your brand.

Check these signs to judge reliability:

Description | |

|---|---|

Production Reliability | On-time delivery rates above 98% show strong logistics. Rates below 75% may mean problems. |

Response Time & Communication | Fast replies (under 2 hours) keep projects on track. Slow responses can cause delays. |

Reorder Rate | High reorder rates (like 66%) show customers trust their quality and craftsmanship. |

Ask your knitwear manufacturer about their delivery history and how they fix problems. Good communication helps you solve issues fast. If you see high reorder rates, other brands trust their quality and skill.

Tip: Always ask for references or reviews from other brands. This helps you learn about the manufacturer’s reliability and sustainability.

If you want a long-term partnership, pick a knitwear manufacturer with strong sustainability and a good record of quality. This makes your brand stronger and helps you grow with confidence.

Lead Times

When you pick a Manchester knitwear manufacturer, you want fast delivery. Lead times tell you how long it takes to get your knitwear. Quick lead times help you follow fashion trends. Slow lead times can hurt your business and leave you with old styles.

Ask each manufacturer how long samples and bulk orders take. Some can finish samples in two weeks. Bulk orders may take four to six weeks. If you want special features or custom yarns, it might take longer. If you need changes quickly, find a manufacturer with flexible scheduling.

Many things can change lead times:

Yarn availability and sourcing

Machine capacity and scheduling

Complexity of your knitwear design

Approval process for samples

Shipping and logistics

Tip: Plan for extra time if you want embroidery, special trims, or eco-friendly materials. These steps can add days or weeks to your lead time.

You can use a table to compare lead times from different manufacturers:

Manufacturer Name | Sample Lead Time | Bulk Order Lead Time | Notes |

|---|---|---|---|

Muff Garments | 2 weeks | 4-6 weeks | Flexible MOQs |

Zam Zam Knitwear | 3 weeks | 6-8 weeks | Advanced patterning |

Britton Intl Ltd | 2-3 weeks | 5-7 weeks | Custom yarn options |

Short lead times help you launch new styles faster. If you want to test new designs or react to market changes, pick a manufacturer with a good record for on-time delivery. This shows their quality and helps you build trust with your customers.

Technology Use in Knitwear Design

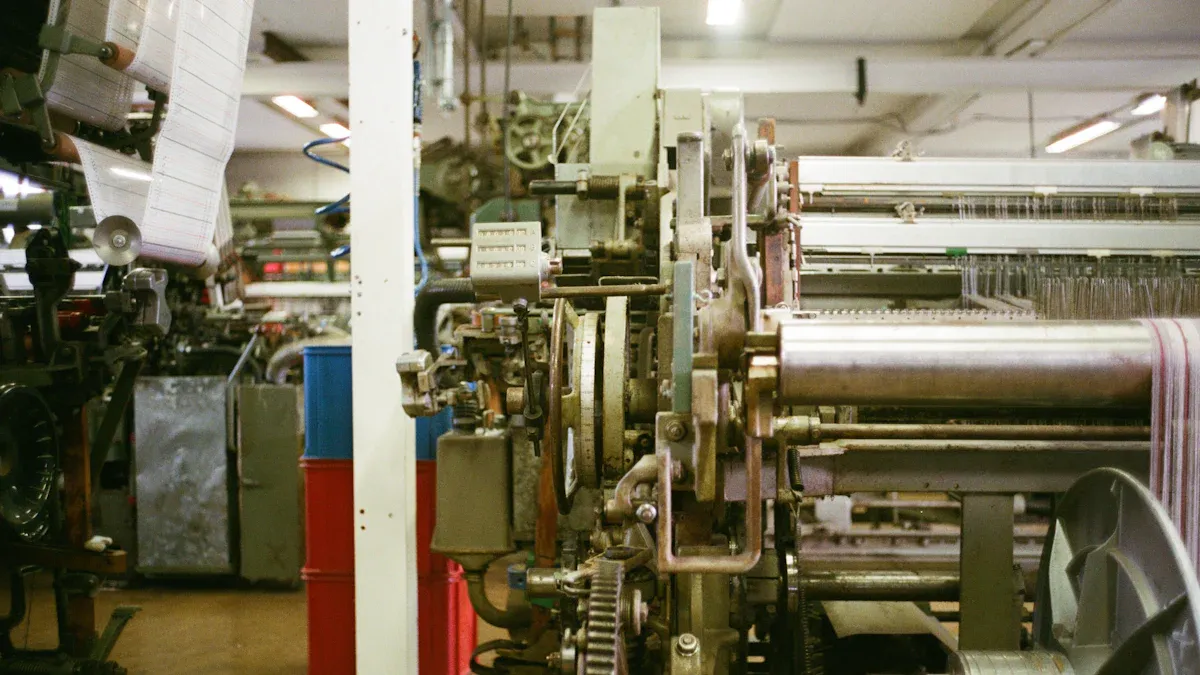

Technology is changing how Manchester knitwear manufacturers make knitwear. Working with a modern manufacturer gives you better accuracy and faster production. You also get more choices for design. Many manufacturers use advanced machines and digital tools to improve quality.

Here are ways technology helps in knitwear design:

3D design tools let you see digital pictures of your product. You can check colors, patterns, and fit before making samples.

These tools replace old pattern-making methods. You save time and avoid mistakes.

Wholegarment technology lets machines make seamless knitwear in one piece. You get more detail and need less manual work.

Advanced machines, like Shima Seiki flat knitting machines, help make complex patterns and switch styles quickly.

Some manufacturers use collaborative robots, called cobots, for stitching and knitting. This makes production faster and supports sustainability.

Note: Technology also helps with sustainability. Digital design tools reduce waste by making fewer samples. Robots and smart machines use less energy and support eco-friendly production.

If you care about sustainability, ask your manufacturer about their technology. Many now use robotics labs and digital design to lower their impact on the environment. This helps you reach your sustainability goals and gives your brand a strong image.

When you pick a Manchester knitwear manufacturer, look for one that uses new technology. You get better knitwear, faster delivery, and more choices. You also help support sustainability and modern craftsmanship in fashion.

Researching Knitwear Manufacturer Options

Online Directories and Reviews

You can look for a knitwear manufacturer online. Directories help you find trusted companies in Manchester. Some good directories are Textile Infomedia and Hula Global. Textile Infomedia lists many knitwear specialists. You can see profiles and contact info. Hula Global shows top clothing manufacturers like Xpose Limited. These sites let you compare services and order sizes. You can also check what each company does best. Always read reviews before you choose. Reviews tell you what other brands think. Good reviews mean the company does a great job. Bad reviews warn you about problems. Trustpilot shows real customer stories. This helps you pick the right manufacturer and avoid trouble.

Tip: Read reviews first. This saves time and helps you stay safe.

Trade Shows and Industry Events

Trade shows let you meet knitwear manufacturers in person. You can look at samples and ask questions. You also learn about new styles and trends. Manchester has big events every year. Here is a table with some upcoming shows:

Event Name | Location | Dates | Categories |

|---|---|---|---|

Manchester, United States Of America | 22nd Mar, 2026 to 24th Mar, 2026 | Apparel, Leather & Footwear, Accessories | |

Manchester Signature Show – May 2026 | Manchester, United States Of America | 17th May, 2026 to 19th May, 2026 | Apparel, Leather & Footwear, Accessories |

BSTA Show – Northeast Expo Shows August 2026 | Manchester, United States Of America | 9th Aug, 2026 to 10th Aug, 2026 | Apparel, Leather & Footwear, Accessories |

Manchester Signature Show – August 2026 | Manchester, United States Of America | 31st Aug, 2026 to 2nd Sep, 2026 | Apparel, Leather & Footwear, Accessories |

BSTA Show – Northeast Expo Shows 2026 | Manchester, United States Of America | 18th Jan, 2026 to 20th Jan, 2026 | Apparel, Leather & Footwear, Accessories |

Manchester Signature Show – 2026 | Manchester, United States Of America | 27th Jan, 2026 to 29th Jan, 2026 | Apparel, Leather & Footwear, Accessories |

At these shows, you can talk to spinners, weavers, and knitters. Events like ‘Make it British Live!’ help you meet the whole supply chain. You get to know experts who care about quality. Some leaders say these shows help brands find new partners. You can see new knitwear styles and learn about new machines.

Note: Trade shows are busy places. Plan your visit and bring samples to show.

Referrals and Recommendations

Referrals make your search easier. Ask other brands or designers for advice. People in fashion share honest feedback. You can learn what a company does well or not so well. Recommendations from people you trust help you avoid mistakes. Join fashion groups or online forums for more tips. Many brands share their stories and give advice on working with manufacturers.

Tip: Grow your network. Knowing more people helps you find the best knitwear partner.

If you use directories, go to trade shows, and ask for referrals, you get more choices. You will find a knitwear manufacturer who fits your brand’s style and values.

Portfolio Assessment

If you want to pick the best knitwear manufacturer, look at their portfolio. A portfolio shows what the company can make. You see real examples from other brands. This helps you know if their style matches your ideas.

Ask for a digital or paper portfolio. Most manufacturers have online galleries or sample books. You can look at pictures or videos. You can also ask for sample pieces. Look closely at each knitwear item. Are the stitches neat? Are the colors bright and even? Does the fabric feel soft or strong? These things show the quality you might get.

Here is a simple checklist for reviewing a knitwear portfolio:

See if there are many knitwear styles. Are there sweaters, cardigans, scarves, or hats?

Look for different fabrics. Cotton, wool, and recycled yarns show they can do more.

Notice the finishing touches. Are there custom labels, embroidery, or special trims?

Check the color range. Can they make bold colors and soft shades?

Ask about past work. Have they made knitwear for brands like yours?

Tip: If you like a style, ask how the manufacturer made it. You can learn about their process and see if they use new technology.

You can use a table to compare portfolios from different manufacturers:

Manufacturer Name | Knitwear Styles | Fabric Options | Special Features | Technology Used |

|---|---|---|---|---|

Muff Garments | Sweaters, hats | Cotton, wool | Embroidery, labels | 3D design tools |

Zam Zam Knitwear | Cardigans, scarves | Recycled yarns | Custom trims | Robotics lab |

Britton Intl Ltd | Jumpers, vests | Wool, blends | Hand finishing | Digital patterning |

When you look at portfolios, check for consistency. Every knitwear piece should meet your standards. If you see messy stitching or faded colors, ask questions. Good manufacturers will tell you how they fix problems and make things better.

Remember to ask for references. Other brands can share their experience with the manufacturer. You get honest feedback and avoid problems.

Portfolio assessment helps you find a partner who understands your brand. You see their skills, creativity, and care for quality. This step makes it easier to choose a manufacturer who can make your knitwear ideas real.

Shortlisting and Contacting Manufacturers

After you make a list of Manchester knitwear manufacturers, you need to contact them. This step helps you find someone who understands your brand. You want a partner who can give you what you need.

Requesting Knitwear Samples

Always ask for samples before you choose a manufacturer. Samples show you the real quality. They help you find problems early. When you ask for samples, do these things:

Ask how much the sample costs and how long it takes.

Find out how they will send the sample to you.

Attach your design files or pictures so they know what you want.

Be polite and clear so there is no confusion.

Tip: Giving lots of details helps you get a sample that matches your idea.

Communication and Responsiveness

Good communication makes working together easier. You want a manufacturer who answers quickly and keeps you updated. Look for these things:

Make sure you and the manufacturer share information clearly.

Get regular updates while they make your sample.

Check if they talk with any outside factories they use.

If a manufacturer replies fast and gives clear answers, that is good. Slow or confusing replies can cause mistakes and delays. You want someone who cares about your project.

Note: Fast and friendly replies help you work better as a team.

Comparing Offers

After you get samples and talk to each manufacturer, you will have offers to compare. Do not just look at the price. Think about what matters most for your brand. Here are things to check:

Quality Control: Does the manufacturer check details? Good checking means your knitwear looks and feels great.

Lead Times: How fast can they finish your order? Local Manchester factories often work faster than faraway ones.

Carbon Footprint: Making products nearby means less shipping. This helps the environment.

Local Economy: Picking a Manchester manufacturer helps local jobs and keeps skills alive.

Ethical Production: Local factories follow strict rules. Workers get fair pay and safe places to work.

You can use a table to compare your choices:

Manufacturer | Quality Control | Lead Time | Eco-Friendly | Supports Local | Ethical Standards |

|---|---|---|---|---|---|

Muff Garments | Excellent | Fast | Yes | Yes | High |

Zam Zam Knitwear | Good | Moderate | Yes | Yes | High |

Britton Intl Ltd | Excellent | Fast | Yes | Yes | High |

Take your time to look at each offer. Pick the manufacturer who fits your brand and can give you what you need. This careful choice helps you build a strong knitwear business.

Factory Visits and Due Diligence

Visiting a Manchester knitwear factory gives you a real sense of how your products will come to life. You get to see the workspace, meet the team, and check if everything matches your brand’s standards. This step helps you avoid surprises and build trust with your manufacturer.

On-Site Assessment

When you walk into a knitwear factory, pay close attention to how things look and feel. You want to spot any problems before you start working together. Here are some things you should check:

Factory organization: Look around. Is the space tidy or messy? A well-organized factory means fewer mistakes and faster production.

Factory capacity: Find the production planning boards. These boards show how the factory manages orders. If you see clear schedules, the team can handle your order size.

Working conditions: Watch for safety signs and equipment. Workers should have clear instructions and safe gear. Good working conditions mean happier workers and better products.

Production equipment: Check the machines. Are they clean and working well? Modern, well-kept equipment helps your knitwear look sharp and last longer.

Warehouse and material inventory: Peek into storage areas. Raw materials and finished products should be stored neatly. This keeps your yarns fresh and your orders safe.

Tip: Take notes and photos during your visit. You can compare factories later and share details with your team.

Facility and Team Evaluation

Meeting the people behind your knitwear is just as important as checking the machines. You want to know who will make your products and how they work together. Here’s what you should look for:

What to Evaluate | Why It Matters |

|---|---|

Skilled workers make better knitwear. | |

Communication | Friendly, clear talk helps avoid errors. |

Management approach | Good leaders keep projects on track. |

Training and safety | Ongoing training means fewer mistakes. |

Staff morale | Happy teams care about quality. |

Ask questions while you tour the factory. How long have team members worked there? Do they get training on new machines or styles? You can also ask about how they solve problems. If the team seems proud of their work, you’ll likely get better results.

Note: A strong team and a clean, safe facility show that the manufacturer cares about quality and your brand’s reputation.

Factory visits help you see the real story behind your knitwear. You get to check the details, meet the team, and make sure your brand will shine. If you take time for due diligence, you set yourself up for success.

Negotiating and Building Relationships

Having a good relationship with your Manchester knitwear manufacturer helps your brand. When you work together, you talk better and make things easier. Problems get fixed quickly. You can make knitwear that matches your ideas. If you want your brand to grow, start with trust and teamwork.

Contract Terms

You need to agree on contract terms before making anything. Clear contracts keep you and your manufacturer safe. They stop confusion and mistakes. Most fashion brands and Manchester knitwear manufacturers talk about these contract terms:

Term | Description |

|---|---|

Quantity | The number of units to be produced. |

Shipment | Terms regarding the delivery of goods. |

Payment | Payment terms and conditions. |

Delivery Dates | Specific dates for when products should be delivered. |

Product Specifications | Quality and design specifications for the products. |

Manufacturer’s Knowhow | Expertise and techniques the manufacturer brings to the production process. |

Ownership of IP | Rights regarding intellectual property created during the contract. |

Liability of Parties | Responsibilities and liabilities of each party involved in the contract. |

Talk about rights for online sales and stores. Make sure you say which products the contract covers, like sweaters or hats. If you want clear prices, ask for a cost breakdown. This shows how order size and design change the price. Big orders can get you discounts, like 10-15% off for 5,000 units.

Tip: Always read the contract closely. Ask questions if you do not understand.

Payment and Returns Policy

Payment terms tell you when and how to pay. You want payment rules that fit your money plan. Some manufacturers want a deposit before they start. Others want full payment after you get your order. Talk about what works for you.

Returns policy is important too. If your knitwear is not good enough, you need a way to return or swap items. Ask your manufacturer how they fix returns. Do they give refunds or new items? What if there are mistakes in your order?

Here is a simple list to help you check payment and returns policies:

Ask about deposit amounts and payment deadlines.

Find out if you can pay in steps for big orders.

Check how the manufacturer handles returns or defects.

Make sure the policy covers problems with quality and craftsmanship.

Note: Good payment and returns rules help you avoid stress and keep your business safe.

Long-Term Collaboration

If you want your brand to last, think about working together for a long time. Staying with the same manufacturer helps you build trust. You get better service and more care. Your manufacturer learns your style and what you want for quality and craftsmanship.

Long partnerships help you plan for the future. You can talk about new designs and next orders. Your manufacturer may give you better prices or faster delivery. You help local jobs and keep skills alive in Manchester.

Here are ways to build a strong partnership:

Talk often and share feedback.

Visit the factory when you can.

Celebrate wins together.

Work on new ideas as a team.

😊 Good relationships make better knitwear and a happier business.

If you use clear contracts, fair payment rules, and teamwork, your brand will do well. You get knitwear that shows real craftsmanship and supports your values.

Choosing the best Manchester knitwear manufacturer means you need to:

Know your brand’s needs

Check quality and cost

Look for reliability

Build strong relationships

Remember, you should always ask questions and keep checking your manufacturer’s work. If you stay involved, your knitwear will match your vision. Ready to take the next step? Start your search today! 😊

FAQ

What is the minimum order quantity for Manchester knitwear manufacturers?

Most Manchester knitwear manufacturers ask for a minimum order of 200 units. Some offer lower minimums, like 12 pieces, if you want to test new designs or start small.

How do you check the quality of knitwear before placing a big order?

You should always ask for samples first. Look at the stitching, color, and feel. If you see neat work and bright colors, you know the quality is good.

Can you use eco-friendly yarns for your knitwear?

Yes, many Manchester manufacturers offer recycled or organic yarns. Just ask about their options. You can choose materials that match your brand’s values.

How long does it take to get your knitwear order?

Sample orders usually take two to three weeks. Bulk orders need four to eight weeks. If you want special features, your order might take longer.

What should you include in your tech pack for knitwear?

Tip: Add clear drawings, color codes, size charts, and fabric details. The more information you give, the better your samples will match your vision.

Do Manchester knitwear manufacturers help with design?

Some manufacturers offer design support. You can share your ideas, and their team will help with patterns, colors, and sizing. Ask about their design services before you start.

How do you handle returns if your knitwear has defects?

Check the manufacturer’s returns policy. Most will replace or fix items with defects. Always agree on the rules before you place your order.

Is it better to visit the factory before you order?

Visiting the factory helps you see how things work. You meet the team and check the machines. If you want to avoid surprises, a visit is a smart move.