You should pick a bulk knitwear manufacturer who fits your needs and helps your business. First, know what you want. Then, look at different choices. Check their work. Talk with them clearly. Make a smart decision. Watch for quality, price, trust, and how much they can make. Many businesses have problems with fabric that shrinks or loses color. They also see sewing mistakes like broken stitches. There can be color problems, wrong sizes, and patterns that do not line up. Pay attention to these things. This will help you avoid big mistakes and have a good partnership.

Key Takeaways

Make sure you know what knitwear you need. This helps you avoid mistakes. It also helps you get the right products.

Pick fabrics that are high quality. Make sure they last long and keep their color. This helps your products look good.

Look up manufacturers in directories. Ask people for referrals. Read reviews to find good partners.

Ask about how they check quality. Find out if they do sampling and inspections. Learn about their standards for making products.

See if the manufacturer can make enough products for you. Make sure they can handle your order size and any changes you want.

Think about how the manufacturer helps the environment. Check where they are located. This can help your brand and save money.

Talk clearly with your manufacturer. This helps you build trust. It also helps you fix problems fast.

Use a checklist to compare manufacturers. Look at quality, price, and how fast they answer you. Do this before you choose one.

Define Your Knitwear Requirements

Before you pick a bulk knitwear manufacturer, you should know what you want. This helps you avoid mistakes and get the right products. Think about what matters most for your business and your customers.

Product Specifications

Fabric, Weight, and Color

Pick the fabric type, weight, and color for your knitwear. These choices change how your products look and feel. Many people like Merino wool, organic cotton, mohair, or viscose blends. These fabrics are soft, let air through, and last a long time. Stitch density is important too. If you use high stitch density, like 12-gauge knitting, your clothes will fit better and look smooth. Make sure the dyes do not fade and the fabric does not pill. This keeps your knitwear looking nice after many washes.

Specification | Details |

|---|---|

Fabric Quality | Merino wool, organic cotton, mohair, viscose blends for softness, durability |

Stitch Density | High density (e.g., 12-gauge) for smooth, structured fit |

Durability | Colorfast dyes (4.5+ rating), anti-pilling treatments |

Size Range and Features

Choose the sizes you want to offer. Think about who will buy your products and what sizes they need. You can add special things like custom labels, embroidery, or cool patterns. These details help the manufacturer know what you want.

Order Volume and Budget

Minimums and Maximums

Decide how many pieces you want to order. Some manufacturers need you to order a certain amount. Others can make very large orders. Make sure your order size matches what the manufacturer can do. This is important when you plan your business.

Cost Planning

It is important to plan your budget. Here is an easy way to figure out your costs:

Find out the base cost for each garment.

Add costs for custom features.

Include setup and labor costs.

Add overhead costs for your business.

Use volume discounts if you order a lot.

Add your profit margin.

Change your plan for your market and customers.

This helps you make a budget that works for you and keeps your business strong.

Quality Standards

Certifications

Ask if the manufacturer has certifications. These show they use safe and good materials.

Compliance

See if the manufacturer follows international quality rules. Quality control means checking fabric, stitching, and color. Light checks are important for dark sweaters, especially with fine gauge. Physical tests like stretching and pulling make sure your products last. Use good dyes and follow care rules to avoid problems.

Tip: If you set clear rules and standards early, you can avoid big mistakes later.

By thinking about these important things, you build a strong start for your bulk knitwear project.

Research Bulk Knitwear Manufacturers

You need to do good research to find the right manufacturer. Make a list of companies that fit what you want. Use trusted websites and tools to get information.

Finding the Best Knit Garments Manufacturer

Industry Directories

Industry directories show many manufacturers in one place. These lists have company names, products, and how to contact them. You can look at different companies and see which ones fit your needs. Some directories only show companies from certain places or with certain products. This makes searching easier.

Platform | Supplier Volume | Product Range | Main Region | |

|---|---|---|---|---|

Alibaba | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ✅✅✅ | Global |

Global Sources | ⭐⭐⭐ | ⭐⭐⭐⭐ | ✅✅ | Asia |

Fibre2Fashion | ⭐⭐ | ⭐⭐⭐ | ✅ | South Asia |

Tradekey | ⭐⭐ | ⭐⭐ | ✅ | MENA |

You can use these sites to sort by order size or delivery time. Verified suppliers and safe payment options help you avoid problems.

Referrals and Trade Shows

Ask other business owners or friends for referrals. People who have used a manufacturer can give honest advice. Trade shows let you meet suppliers in person. You can see samples and ask questions about how they work. This helps you decide if a company is right for you.

Online Presence and Reputation

Reviews and Testimonials

Look at reviews on business websites and other sites. Reviews tell you if a company is on time and makes good products. Check ratings and what customers say. These things help you know if a company is reliable.

Tip: Read good and bad reviews. This helps you see both the strong and weak points of a manufacturer.

Portfolio Assessment

Go to the manufacturer’s website and look at their portfolio. Check if they have made things like what you want. A good portfolio shows they have made many styles and used different fabrics. You want a company that can make what you need and do custom work.

Metric Type | Description |

|---|---|

Engagement Metrics | Shows how customers interact with the brand’s content. |

Reflects customer satisfaction through reviews and ratings. | |

Responsiveness Metrics | Measures how quickly and well the company answers questions. |

When you research, look for things like experience and if they can make your order size. The best manufacturer will have good reviews and a strong history. Always look at a few companies before you pick one.

Evaluate Quality and Craftsmanship

When you pick a bulk knitwear manufacturer, you need to check quality and craftsmanship. These things help your products make customers happy and help your business grow. You should see how the manufacturer checks quality and how much skill they have in making knitwear.

Quality Control Processes

Quality control is very important for good knitwear. You should ask the manufacturer about their steps for checking quality. The best manufacturers use many checks to make sure every item is good.

Sampling and Prototypes

Samples and prototypes are important for quality and craftsmanship. You need to look at samples before making a big order. This helps you test the fit, materials, and how things look. You can find problems early and fix them before they cost a lot. The process has these steps:

Phase | Description |

|---|---|

Initial Concept | The manufacturer makes the first design and asks for your approval. |

Prototype Acceptance | You test and approve the first sample before moving forward. |

Pre-Production | The manufacturer gets ready for making lots of items. |

You should ask for different samples:

Development samples show the first idea of your design.

Fit and size set samples help you check comfort and sizing.

Salesman and pre-production samples let you approve the final look.

Tip: Always look at samples in person. This helps you see the real quality and craftsmanship before you decide.

Inspection Procedures

Inspection is a big part of quality control. You want to know the manufacturer checks every detail. Here are common inspection steps used by top bulk knitwear manufacturers:

Check yarn for color, strength, and dirt.

Look at pre-production samples for how they are made.

Check samples in all sizes for fit.

Do random checks of knitted panels while making them.

Look at finished panels after knitting.

Check seams during linking for neatness.

Look at linked garments for mistakes.

Check hand-hemmed edges for neatness.

Use bright light to find hidden problems.

Check garments after washing for shrinking and color bleeding.

Measure garment sizes to match approved specs.

Check cleaned garments before packing.

Do carton-wise checks using AQL standards.

Allow for client or third-party inspection.

Manufacturers also check fabric in safe, bright places. They look at color, texture, and weight to match standards. They measure fabric width and length and look for problems. These steps help you avoid color and size mistakes.

Note: Good quality control means fewer returns and happier customers.

Assessing Manufacturer Experience

You should look at the manufacturer’s experience to see their quality and craftsmanship. Skilled manufacturers know how to avoid mistakes and make good products.

Past Projects

Ask the manufacturer to show you past work. Look for work with famous brands or hard designs. This shows they can do what you need. You might see examples like this:

“Integrating our technology into Johnstons’ factory is a big step for Unmade and shows our idea works at a big scale. Johnstons is known for luxury knitwear and uses old and new techniques. This made them the best first partner for Unmade.”

This kind of history shows the manufacturer cares about quality and craftsmanship.

Client References

You should ask for client references. Talking to other buyers helps you learn if the manufacturer is reliable. Skilled manufacturers often get approval from buyers before making lots of items. They use quality checks to find problems early. They also know how to manage costs and prices, which shows they are good with budgets.

Approval from buyers means you see the exact look and feel before making lots of items.

Quality checks look at fabric and find problems early.

Costing and pricing help you plan your budget and avoid surprises.

Tip: Good manufacturers build trust by sharing references and showing they care about quality control.

When you focus on quality and craftsmanship, you protect your brand and make sure your products are special. You need to check samples, look at inspection steps, and see the manufacturer’s experience. These actions help you pick a partner who cares about quality and makes great knitwear every time.

Assess Production Capacity and Customization

When you pick a bulk knitwear manufacturer, check if they can make enough items for you. Make sure they can also give you the custom options you want. This step helps you avoid waiting too long for your order. It also helps you get products that fit your brand.

Production Capabilities

Facility Size

The size of a manufacturer’s factory shows how much they can make at once. Big factories use special systems to finish orders fast. They also use checks to keep the material good. Ask about their machines and how many people work there. A bigger factory can take more orders and save you money.

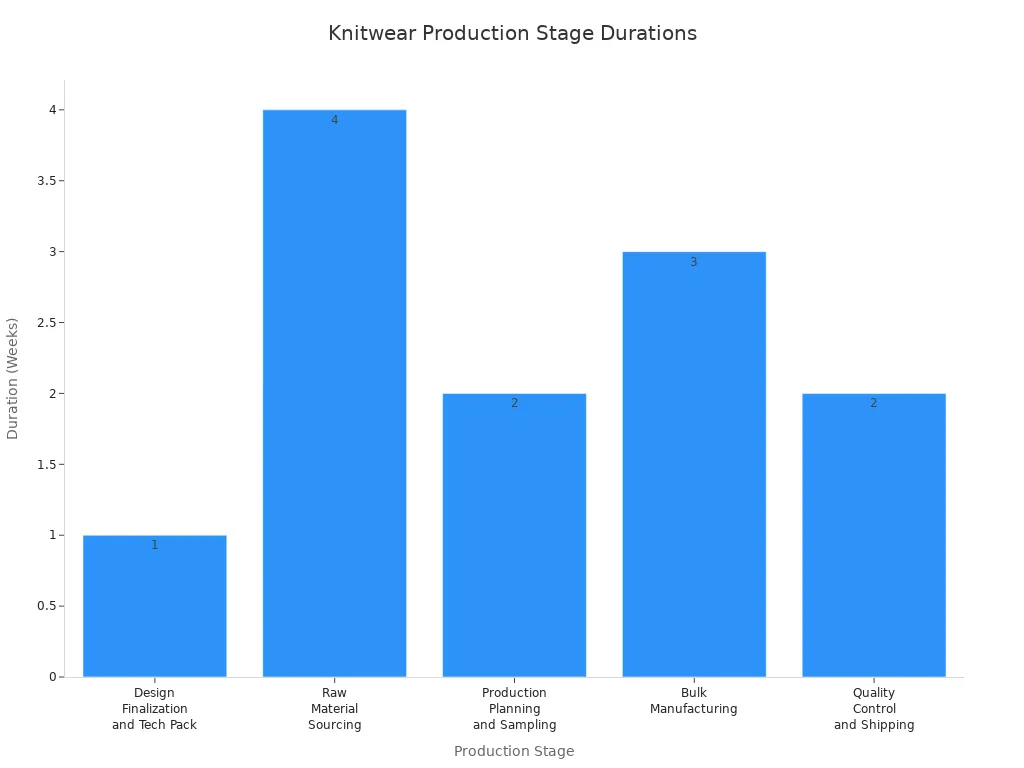

Lead Times

Lead time is how long it takes to get your finished products. You want a manufacturer who can deliver on time, even for big orders. Here is a table that shows each step and how long it takes:

Stage of Production | Duration (Weeks) |

|---|---|

Design Finalization and Tech Pack | 1 |

Raw Material Sourcing | 4 |

Production Planning and Sampling | 2 |

Bulk Manufacturing | 3 |

Quality Control and Shipping | 2 |

Most bulk knitwear orders take about 45 to 75 days. The time can change if you order more or use special materials. For example, polyester knitwear may take about 35 days. Sportswear with many fabrics can take up to 55 days. Custom knitwear takes longer than printed items because it needs more care and checks.

Tip: Always ask for a clear timeline before you order. This helps you plan your sales and avoid problems.

Customization Options

Design Flexibility

Customization lets you make products that match your brand. Good manufacturers let you pick your own designs, patterns, and colors. Some companies let you order as few as 50 pieces. You can choose from many fabrics, like ones that are good for the planet. This helps you be creative and save money.

Feature | Details |

|---|---|

Minimum Order Quantity | Just 50 pieces |

Design Flexibility | Complete freedom for unique designs, patterns, and colors |

Fabric Selection | Sustainable, ethical, and long-lasting fabrics |

Production Speed | As fast as 14 days from idea to product |

Logo Inclusion | Add your logo on private labels |

Special Features

You can add special things to your knitwear, like custom labels or embroidery. Many manufacturers help you make your brand stand out. You can pick from lots of colors and patterns, even custom prints. Some companies offer sizes from XS to 3XL, so more people can wear your products.

Customization helps you give customers what they want and build your brand. It also lets you order only what you need, which saves money. When you look at custom options, check if the manufacturer can make more as your business grows. This helps you balance creativity, quality, and cost.

Note: The best manufacturers can make lots of products and offer many custom choices. This helps your business grow and keeps your customers happy.

Sustainability and Location Factors

When you pick a bulk knitwear manufacturer, think about how they help the planet and where they are. These things change how people see your brand, how much you pay, and how fast you get your items.

Sustainable Practices

Ethical Sourcing

Ethical sourcing means the manufacturer uses safe materials and treats workers well. Many buyers want brands that care about people and nature. You can look for certifications to see if a manufacturer follows good rules.

Certification | Description |

|---|---|

Shows organic materials and fair labor. | |

Fair Trade | Makes sure workers have rights and support. |

OEKO-TEX | Proves textile safety and no toxic dyes. |

“We make sustainable clothes using: BCI – Better Cotton Initiative, MULESING FREE – BIO YARNS, RECYCLED FIBERS.”

If you work with a manufacturer who has these certifications, your products are easier to sell. Customers trust brands that care about workers and the earth.

Environmental Responsibility

You should also check how the manufacturer helps the environment. Many factories use solar panels to make less pollution. They use eco-friendly materials and try to make less waste.

Standard/Practice | Description |

|---|---|

GOTS | Organic textiles made in a good way. |

OEKO-TEX | Textiles with no harmful stuff. |

Eco-friendly dyeing | Dyeing that uses less water and chemicals. |

Waste management | Plans to cut and handle textile waste. |

Energy efficiency | Ways to use less energy when making things. |

Some manufacturers use a batch model with low minimums. This helps you not order too much and keeps warehouses from filling up. Factories that save resources and use green materials help you protect the planet.

The EU now wants manufacturers to pay for textile waste. These rules make companies cut waste and make longer-lasting products.

Manufacturer Location

Shipping and Logistics

Where your manufacturer is changes how fast and how much it costs to ship. Factories in cities ship faster and for less money because they are close to delivery places. Factories far away may cost more and take longer.

Factories near ports or airports ship products quickly.

Orders from other countries may have customs checks and delays.

Shipping to cities costs less than shipping to far places.

Ask your manufacturer about their shipping and how they move products. This helps you plan and avoid problems.

Regional Advantages

Some places are better for bulk knitwear. For example:

India is famous for textiles. Tamil Nadu makes cotton knits, Karnataka makes silk, and Punjab does embroidery.

Bangladesh is a top knitwear exporter and has low labor costs.

Many Asian countries have lots of raw materials and big factories.

These places often care about the planet and can make big orders.

Picking the right place helps you save money, get products faster, and offer cool styles to your customers.

Tip: When you choose a manufacturer, think about their green actions and where they are. This helps your business grow and keeps your customers happy.

Communication and Building Relationships

Making a good relationship with your manufacturer is more than signing papers. You need to talk clearly from the start. Good talking helps you stop mistakes and fix problems fast. It also helps you trust each other. Trust makes your business strong for a long time.

Choosing the Right Knitwear Manufacturer

Responsiveness

Pick a manufacturer who answers you fast and clearly. Quick replies show they care about your time. Fast feedback helps you make choices quickly. It keeps your project moving. A good manufacturer will tell you about your order often. They will let you know if anything changes.

Here are some ways to talk well with your manufacturer:

Say all details clearly so no one gets confused.

Respect different cultures to build trust.

Set clear rules for design, time, and quality.

Use tools like email or chat to talk.

Give feedback fast to keep things going.

Fix problems calmly and with respect.

These steps help you work well with your manufacturer.

Transparency

Transparency means your manufacturer tells you everything important. This includes prices, time, and any problems. If the company is open and honest, you feel safe. Trust and openness make a good partnership. You should always know what is happening. This way, you do not get surprised.

Trust grows when both sides share news.

Fast service shows the company cares.

Clear prices and honest updates help you plan.

Long-Term Partnership

Shared Values

Long partnerships work best when you and your manufacturer care about the same things. You both need to care about quality and good talking. You should want to work together for a long time. If you both care about trust and growth, you avoid problems. Do not pick someone who only wants the lowest price. Pick a partner who cares about your success too.

Support for Growth

A good manufacturer helps your business get bigger. They help you fix problems and give new ideas. They change with your needs. If you talk well and get good service, you can face problems together. This help makes your business stronger. It helps you reach your goals.

Tip: Pick a manufacturer who cares about trust, shares your goals, and helps you grow. This will help you have a strong partnership.

Making the Final Decision

Picking your bulk knitwear partner is important. You should feel sure before you sign anything. Take time to look at all your choices. Make sure you pick the best one for your business.

Comparing Options

Pros and Cons

Make a list of good and bad points for each manufacturer. This helps you see which one fits your needs. Look at these things:

Production capacity: Check how many pieces each company can make.

Lead times: Ask how long orders take to finish.

Flexibility: See if they can handle rush orders or changes.

Sustainability practices: Look for eco-friendly materials and green ways to make clothes.

Pricing: Compare prices and see what you get for your money.

Manufacturer reviews: Read what other buyers say about quality.

Sample orders: Order samples to check quality before buying a lot.

Communication: Notice how fast and clear each company answers you.

Tip: Use a simple table or checklist to keep track of what you find. This makes it easy to compare important things side by side.

Decision Checklist

Before you choose, ask yourself these questions:

Does the manufacturer meet your quality needs?

Can they make the number of items you want?

Do they offer the custom features you need?

Are their prices clear and fair?

Do they have good reviews and strong references?

Are they easy to talk to and open about their work?

Do they support your business values and plans to grow?

A checklist helps you stay organized and not forget anything.

Negotiating Terms

Contracts

When you pick your manufacturer, you need a clear contract. This keeps you and the supplier safe. Good contracts list product details, delivery times, quality checks, and what happens if there is a problem. You can use different ways to talk about deals. Sometimes, you ask for the best deal. Other times, you try to find a middle ground or build a strong partnership. Always get ready before you talk and learn what matters most to the supplier.

Note: Knowing about cultural differences can help you avoid problems, especially with partners from other countries.

Payment Terms

Talk about payment rules before you start. Decide if you will pay all at once or in parts. Some companies want a deposit first, then the rest after delivery. Try to balance saving money with getting good quality and service. If you want to work together for a long time, talk about flexible rules that help both sides during busy or slow times.

Tip: Check your agreement often. This helps you keep up with changes and keeps your partnership strong.

By following these steps, you make a smart choice and build a good relationship with your clothing manufacturer.

You can find good knitwear manufacturers by using easy steps. First, think about what you need for your business. Then, look up different companies and see what people say about them. Always ask for samples to check if the products are made well. Make sure the materials are good too. Talk often with your supplier so you do not make mistakes. This will help you reach your goals and keep your business strong. Use this guide to help you every time you order.

Tip: Always check for good quality and talk openly with your supplier to do well for a long time.

FAQ

What should you look for in a bulk knitwear manufacturer?

Check if the quality is good. Make sure they can make enough products. See if they are reliable. Ask them for samples to check their work. The bulk knitwear manufacturer should meet your needs and finish on time. Look for clear talking and good reviews from other brands.

How do you know if you found the right knitwear manufacturer?

You found the right knitwear manufacturer if they get your ideas. They give you choices and finish orders on time. They answer your questions fast. Their past work looks like what you want and meets your quality needs.

Can a bulk knitwear manufacturer help a startup fashion brand?

Yes, a bulk knitwear manufacturer can help a new fashion brand. Many let you order small amounts and help with design. You can grow your business by using their skills and tools.

How do you compare different bulk knitwear manufacturers?

Write down what you need. Compare each bulk knitwear manufacturer by price, quality, and how fast they work. Check if they let you change designs. Use a table to keep track. Ask for references and look at their old projects.

Tip: Always ask for samples before you order a lot.

What questions should you ask the right knitwear manufacturer?

Ask about the smallest order you can make. Ask how long it takes to finish. Check if you can change designs. See if they follow quality rules. Ask how they fix problems. The right knitwear manufacturer will answer clearly and explain their steps.

How do you build a long-term relationship with the right knitwear manufacturer?

Talk often to build trust. Give feedback and share your plans. The right knitwear manufacturer will help you grow and fix problems fast.

What makes a perfect manufacturer for your business?

A perfect manufacturer gives you good quality and delivers on time. They have fair prices and help you grow. You feel sure working with them.

Can you switch to a new bulk knitwear manufacturer easily?

You can switch, but you need to plan. Check your contracts and test samples first. Make sure the new bulk knitwear manufacturer knows what you want and can give you the same or better quality.