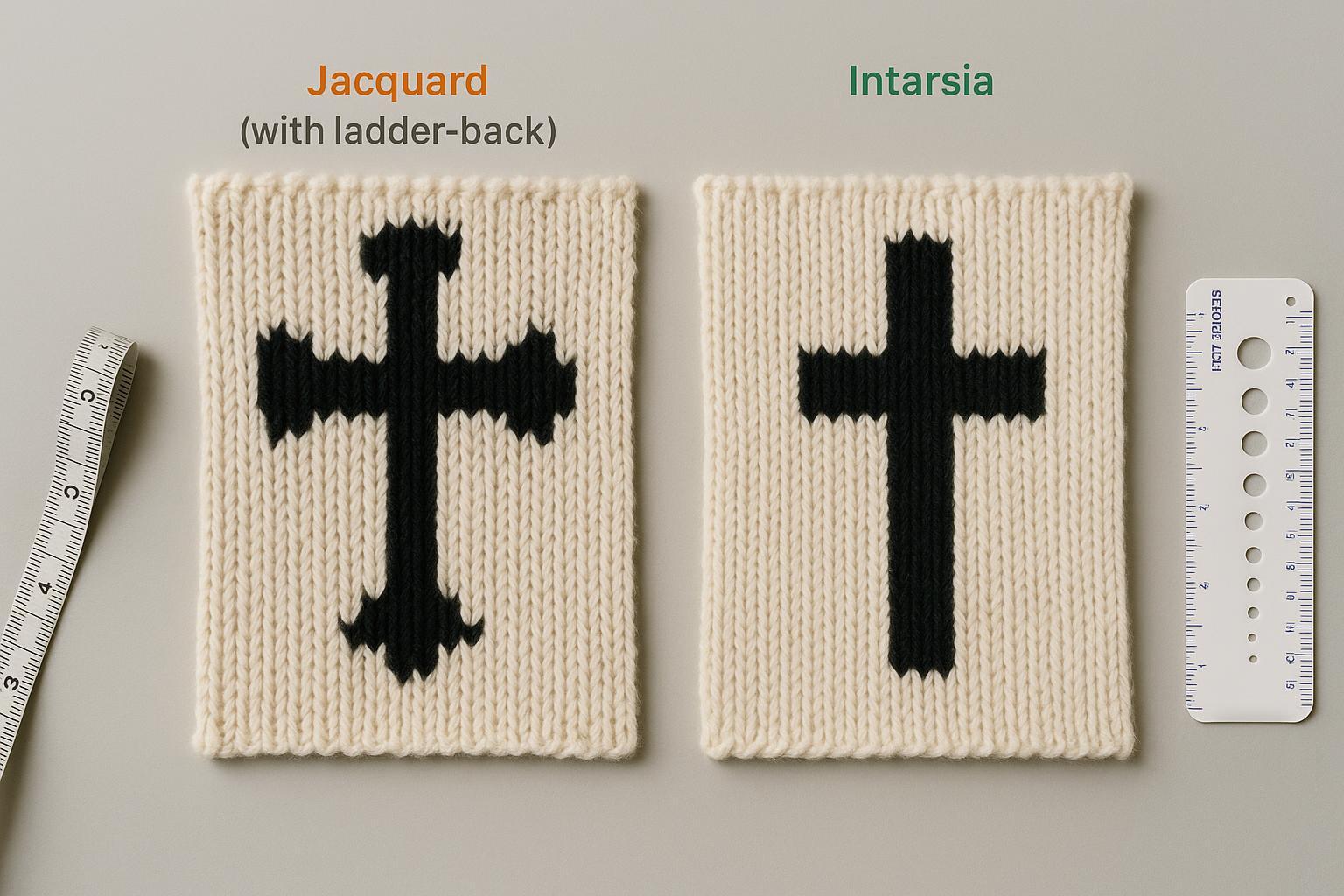

If you’re planning a bold, two‑color gothic cross on a heavy‑gauge sweater, you’re likely weighing jacquard vs intarsia. At 3–7GG, the decision hinges on drape and thermal bulk, programming and runtime under low MOQ, and how clean the reverse must be for real‑world wear.

Key takeaways

For the fastest path to scale and a dense, heavy hand, jacquard typically wins; use ladder‑back to control long floats and improve reverse comfort.

For the sharpest right angles and a truly clean reverse, intarsia excels; expect more setup, slower runtime, and tighter QC at joins.

Your gauge matters: 3GG tends to magnify float spans, 5GG is the workhorse for heavy pullovers, 7GG rewards edge fidelity and cleaner drape; keep 12GG as a control to sanity‑check artwork behavior.

Keep float spans within about 1 inch or 5–6 stitches at these gauges; beyond that, add catches or switch to ladder‑back jacquard according to industry guidance from 2025–2026 sources.

Quick verdict and who wins when

If you prioritize heavy drape, thermal bulk, and predictable throughput on a repeated motif, choose jacquard and plan ladder‑back for long cross arms. If you need crisp right‑angle edges and a clean reverse for close‑up viewing or inner‑layer wear, choose intarsia and budget extra programming and finishing time. These patterns align with current machine capabilities noted by major flatbed makers; advanced intarsia carriers can narrow the gap, but not erase it as of 2026.

Comparison matrix by heavy gauge

The matrix below synthesizes public manufacturer notes and technique explainers as of 2026‑02‑02. Items marked machine‑dependent can vary by model, carrier count, and software features.

Dimension | Jacquard (incl. ladder‑back) | Intarsia |

|---|---|---|

Gauge fit 3–7GG with 12GG control | Broadly reliable for 3–7GG and beyond; repeats scale well; 12GG works when floats stay short. See Stoll CMS/ADF literature for gauge context. | Viable across mid gauges; coarse gauges increase carrier and handling overhead; advanced intarsia carriers and auto allocation help. Machine‑dependent. |

Edge sharpness on gothic crosses | Good but staircase or color bleed can appear at tight right angles; chart smoothing and density tuning help. | Typically the crispest edges since colors knit only where needed; clean boundaries favored for high‑contrast crosses. |

Reverse cleanliness and floats | Floats on the back; keep spans short or use catches; ladder‑back creates hidden support columns for a smoother reverse. | Truly clean reverse with no floats; manage joins to avoid tiny holes and maintain tension. |

Safe float span guidance | Keep floats near or under ~1 inch or ~5–6 stitches at these gauges; beyond that, add catches or ladder‑back. | Not applicable; no floats. |

Programming and setup time | Lower for simple two‑color repeats; fewer carrier constraints; quicker path to first runnable program at low MOQ. | Higher; section‑by‑section programming and carrier allocation; auto‑allocation software reduces but does not remove complexity. |

Runtime throughput | Faster in typical cases; continuous runs with fewer stops; intarsia is often ~30–50% slower depending on machine. | Slower; more carrier actions and stoppages per row; speed varies widely with model and artwork. |

Bulk repeatability and yield | Strong for repeated motifs; fewer join defects; snag risk if floats are long or unmanaged. | Sensitive to operator skill at joins; holes and tension artifacts require vigilant QC; repeatability improves with experience. |

Color count and placement | Practical color‑per‑row limits track carrier availability; more colors add weight and float complexity. | Higher per‑row section flexibility on machines with many intarsia carriers; precise placement without floats. |

Drape and handfeel | Added bulk and warmth from floats; can feel stiffer at dense settings; ladder‑back adds structure. | Single‑layer fabric drapes cleaner with a heavy look but less trapped bulk; smoother inner feel. |

Finishing and assembly | Lower linking at colorwork; float grooming and ladder‑back setup add modest time. | More linking or knotting at joins; careful finishing to prevent holes; minutes per panel trend higher. |

Cost drivers at low MOQ | Generally lower unit cost thanks to faster setup and runtime; ladder‑back adds some time and yarn. | Higher unit cost due to programming, carriers, slower runtime, and extra finishing; becomes more predictable with experience and stable artwork. |

References in context: Stoll CMS/ADF brochures discuss carrier options and gauge context; Shima’s features pages describe intarsia carrier optimization; multiple technique resources advise the ~1‑inch or 5–6‑stitch float rule and ladder‑back methods.

How drape, floats, and edge fidelity play together in jacquard vs intarsia

Think of floats like a thin lining stitched to the back of your sweater: they add warmth and heft, but they can also reduce fluidity and introduce snag risk. That’s why heavy jacquards often feel warmer and more structured than comparable intarsia pieces at the same gauge. Technique sources across 2025–2026 recommend keeping floats near or under about 1 inch or 5–6 stitches before adding catches or switching to ladder‑back support, a practice echoed by knit engineering tutorials and brand‑agnostic machine‑knitting guides published in recent years. See the float‑span discussion in the Japanese‑language KNIT MAGAZINE from 2025 and the product guidance by Kniterate on safe spans for stranded work for practical ranges presented to makers.

According to KNIT MAGAZINE’s float management article (2025), designers should limit floats to roughly 1 inch before securing; this aligns with workshop teaching in many colorwork resources. Read the principle explained in the publisher’s technical note: the guidance is qualitative and gauge‑dependent while still actionable for production teams. Link: the publisher’s float guidance is summarized in the KNIT MAGAZINE overview of float control (2025).

Kniterate’s public product documentation notes the practical rule of thumb of about 5–6 stitches for unmanaged floats; that aligns with a wide body of practice‑led tutorials including modern ladder‑back how‑tos. See the Kniterate machine guidance on stranded knitting safety ranges (2026 product page).

For edge fidelity on high‑contrast gothic crosses, intarsia’s stitch‑accurate color placement yields the cleanest right angles. Jacquard can approach that sharpness with chart optimization and careful density, but the inherent stranded nature makes hard edges slightly more challenging.

Citations: KNIT MAGAZINE float guidance (2025); Kniterate product guidance (2026); technique explainers on ladder‑back from independent educators.

Setup time, runtime, and low‑MOQ cost drivers (time‑stamped 2026‑02‑02)

At low MOQs, the hidden cost is time. Intarsia’s section‑by‑section programming and carrier allocation extend engineering hours and increase runtime stops, while jacquard often reaches a runnable state faster for two‑color repeats and runs with fewer interruptions. Manufacturer materials describe software assistance that reduces intarsia’s setup burden, such as Shima Seiki’s intarsia carrier auto allocation on recent models; nonetheless, the per‑row complexity keeps runtime slower than jacquard for repeated motifs as of 2026. On finishing, intarsia needs meticulous linking or knotting at color joins, whereas jacquard shifts labor to float management or ladder‑back execution.

If you want a deeper primer on the mechanics, floats, and cost drivers of each approach, see the technique explainer on jacquard and intarsia knit techniques (Knitwear.io, 2025). For teams balancing development speed, the quick workflow outline for 3–5 day sampling offers a practical timeline view (Knitwear.io, 2025).

External context: Shima Seiki’s public features describe intarsia‑oriented carrier and software functions (2024–2025), while Stoll’s CMS/ADF brochures highlight carrier capacity and gauge options, shaping what’s feasible per row. Trade and manufacturer‑neutral guides consistently estimate that intarsia tends to be roughly 30–50% slower to run than an equivalent jacquard repeat, with caveats by model and artwork.

Links cited in this section: Shima Seiki product features for intarsia carrier optimization (2024–2025), Stoll CMS/ADF literature on carrier and gauge context (2021+), and the Knitwear.io technique explainer noted above.

Scenario walk‑throughs

5GG heavy pullover — 600 to 700 g range

For long horizontal spans in the cross arms, jacquard is typically the production‑friendly pick. Keep floats near or under ~1 inch or 5–6 stitches; switch to ladder‑back on wider arms to control snag risk and improve reverse comfort. Choose intarsia if the garment will be scrutinized up close and worn against the skin; allocate extra time for programming and finishing to prevent join holes.

7GG boxy cardigan — 500 to 600 g range

When edge crispness and a clean reverse take priority, intarsia shines at 7GG. The fabric drapes cleaner with less trapped bulk, and sharp right angles read well in high contrast. Jacquard still works when the motif can be tiled into repeats that keep floats short; ladder‑back helps if spans grow.

3GG sweatshirt block — 800 g and above

Throughput and rugged hand dominate here. Jacquard is the safer choice at this coarse gauge, but you’ll almost certainly need ladder‑back to tame very long floats in the cross arms. Intarsia becomes feasible if quantities are small and reverse cleanliness is non‑negotiable, but expect a meaningful runtime penalty.

12GG control dress — 350 to 450 g window

Use this as a reality check. If the artwork looks brittle or pixelated at 12GG, it will be even more demanding at 3–7GG. Intarsia provides the cleanest reverse and a smoother drape for close‑to‑skin wear; jacquard is viable for micro repeats where floats are naturally short.

FAQs

Q: What’s the safest float length for a heavy‑gauge jacquard gothic cross?

A: As of 2025–2026, many technical sources converge on about 1 inch or 5–6 stitches as a practical ceiling before adding catches or switching to ladder‑back. Always swatch at your target density, yarn, and gauge.

Q: Can intarsia scale for small‑batch production without defects at joins?

A: Yes, but it demands experienced programming and vigilant QC during linking to avoid tiny holes or tension artifacts. First‑pass yield improves as the team gains familiarity with the motif and yarn.

Q: Which technique gives the sharpest right‑angle edges on the cross arms?

A: Intarsia, because color exists only where needed. Jacquard can be excellent with chart smoothing and density tuning, but stranded knitting can show staircase effects at acute corners.

Q: How do carrier limits affect color placement per row?

A: On many CMS and ADF‑class machines you’ll find practical ceilings tied to carrier availability; intarsia‑ready models support many independent carriers and, with auto allocation software on some platforms, can place multiple sections per row without floats. Capacity and speed remain model‑dependent.

Also consider swatch tests

Disclosure: Xindi Knitwear (Knitwear.io) is our product. If you’d like neutral, two‑color swatches that document float lengths, stitch density, and reverse cleanliness at 3GG, 5GG, and 7GG, you can request swatch tests from Xindi Knitwear; the team supports low MOQs with documented inline QC and balanced jacquard, ladder‑back, and intarsia options.

Methods and sources in brief (2026‑02‑02): Technique mechanics and cost drivers summarized from public explainers and manufacturer features, including Stoll’s CMS/ADF literature on carriers and gauges and Shima’s intarsia carrier optimization. Float span guidance aligns with KNIT MAGAZINE’s 2025 discussion and Kniterate’s product notes; ladder‑back methods are documented by independent educators. For a deeper primer on floats, reverse cleanliness, and finishing labor, see Knitwear.io’s technique and finishing pages.

Further reading with descriptive sources:

According to the KNIT MAGAZINE float control explainer (2025), floats should be secured beyond roughly 1 inch: https://www.maruyasu-fil.com/knit-magazine/1988

The Kniterate guidance on stranded knitting safe spans (2026 product page) references the 5–6 stitch rule: https://www.kniterate.com/product/kniterate-the-digital-knitting-machine/

Shima Seiki product features on intarsia carrier optimization (2024–2025): https://www.shimaseiki.com/product/knit/feature/

Stoll CMS Performer brochure with intarsia options and carrier context (2021): https://www.stoll.com/ecomaXL/files/Performer_EN_21.pdf

A neutral primer on technique trade‑offs is outlined in the Jacquard and Intarsia Knit Techniques overview (Knitwear.io, 2025): https://knitwear.io/jacquard-intarsia-knit-techniques/

Related internal resources for context:

Heavy‑gauge planning and gauge windows are discussed in the Sweater Manufacturing Guide (Knitwear.io): https://knitwear.io/sweater-manufacturing-guide/

Finishing and assembly time implications are covered in Knitwear Finishing and Assembly (Knitwear.io): https://knitwear.io/knitwear-finishing-assembly/

For teams compressing development cycles, see Quick Sampling for a 3–5 day workflow (Knitwear.io): https://knitwear.io/quick-sampling/