Choosing the right rib knit sweater manufacturer is important. It helps your clothing brand look good. If you work with a team that knows knit techniques, you get sweaters that look the same every time. These techniques include cut and sew, panel knitting, and whole-garment knitting. Manufacturers who know rib knit and rib spandex fabrics help you make clothes that fit well. These clothes also feel nice to wear. A good partner cares about quality. They listen to what you want. They help you make custom sweaters. Check how they keep quality high. See if they use eco-friendly ways. Make sure they talk to you clearly. Your choice can change how many clothes get returned. It can change how your brand affects the planet. It can also change how much customers trust you.

Here’s a quick look at how picking a manufacturer can change your brand:

|

Impact Type |

Description |

|---|---|

|

Financial Losses |

53% of clothes get sent back because of size and fit problems. This makes brands lose a lot of money. |

|

Environmental Damage |

Sending clothes back makes more pollution and trash. This hurts your brand’s eco-friendly goals. |

|

Operational Issues |

Sizes that do not match cause slow design work and late product launches. |

|

Strategic Risks |

Brands that do not use the same sizes can lose their good name and customer trust. |

Key Takeaways

-

Picking the right rib knit sweater maker is very important for your brand.

-

Find makers who know a lot about rib knit fabrics. This helps keep the quality and look the same every time.

-

Look for makers who check their work and have certificates. This shows they follow high standards.

-

Customization lets you make special designs for your brand. Your brand can stand out with these unique styles.

-

Sustainability is important. Pick makers who use eco-friendly materials and good practices.

-

Talk clearly with your maker. This helps stop mistakes and delays.

-

Check if the maker can make enough sweaters for your needs. They should handle both small and big orders.

-

Always ask for samples before you order a lot. This helps you check the quality and fit.

Manufacturer Expertise

If you want to make rib knit sweaters, pick a manufacturer who knows a lot about rib fabric. They should understand how to make clothes well. The best manufacturers have worked for many years. They have strong skills. This means your clothes will feel nice, fit right, and last long.

Rib Knit Sweater Manufacturer Experience

Years in Industry

Check how long the manufacturer has made rib knit clothes. More years means they have solved many problems. If they have made rib fabric clothes for a long time, you can trust them. Rib knit fabric can be hard to work with. Some companies have made rib fabric clothes for decades. They have seen many styles come and go. They know what works best.

Client Portfolio

A good client portfolio shows the manufacturer’s skills. Look for companies that work with big brands and small ones. This means they can help many types of clothing brands. Top manufacturers share stories about their work. These stories show how they helped brands grow. They make high-quality rib fabric clothes. Here is how some big brands work with their manufacturers:

|

Manufacturer |

Strategies |

Results |

|---|---|---|

|

Zara |

Easy online shopping, good communication, strong support after buying |

More happy customers, better loyalty and referrals |

|

Nike |

Uses new technology, gives personal service, helps customers quickly |

Very happy customers, bigger market share |

|

H&M |

Fast shopping, great help after buying, talks to customers often |

More loyal customers, better support after buying |

When you see a portfolio like this, you know the manufacturer can make good rib knit clothes for any brand.

Technical Capabilities

Custom Knitting Skills

You want your clothes to look special. So, you need a manufacturer with custom knitting skills. They should know how to make different rib fabric patterns. Some can make rib knit blends for more stretch or softness. The best ones use new machines and skilled workers. This helps them make clothes that match your ideas. They can change the rib fabric to fit your needs. You can get tight or loose styles.

Rib Knit Fabric Knowledge

Not all rib knit fabric is the same. Some stretch more. Some feel softer. Some keep their shape after many washes. A good manufacturer knows these things. They help you pick the best rib knit fabric for your clothes. They test the fabric for quality. This means your clothes will last longer and look better. Here are some skills that make top manufacturers stand out:

|

Capability |

Description |

|---|---|

|

Advanced Customization |

They control patterns, yarn, and design for special looks. |

|

Superior Elasticity and Stretch |

Ribbed knit is stretchy and strong, good for moving a lot. |

|

Efficient Manufacturing Processes |

New ideas and options make making clothes faster and better. |

If you pick a manufacturer with these skills, your rib fabric clothes will be comfy and high quality.

Tip: Ask your manufacturer for samples of rib knit clothes. This helps you check the quality before you order a lot.

If you want your brand to grow, choose a rib knit sweater manufacturer who knows rib fabric well. Their experience and skills help your clothes look and feel great.

Quality Assurance

When you pick a rib knit sweater manufacturer, you want to trust the quality. Quality assurance is not just a big word. It means your sweaters look nice, feel good, and last long. You need a manufacturer who checks quality at every step.

Quality Control

Inspection Protocols

Quality control starts with careful checks. Workers look at each piece of clothing. They look for problems like bad stitching or loose threads. They also check for mistakes in the rib knit fabric. Some manufacturers test how much the rib fabric stretches. If a sweater does not pass, it gets rejected. Only the best clothes go to your customers.

Certifications

Certifications show a manufacturer cares about quality. These certificates prove the company follows strict rules for rib fabric clothing. Here are two important certifications to look for:

|

Certification |

Description |

|---|---|

|

ISO 9001 |

Focuses on quality management systems, keeps customers happy, and helps the company get better. |

|

GOTS |

Shows the clothing uses organic rib knit fabric and meets tough rules for the environment and people. |

-

Certifications help you trust the manufacturer.

-

They make your clothes more attractive to buyers.

-

Following these rules gives your brand a boost in the market.

Consistency

Sample Review

You want every batch of rib fabric clothes to look and feel the same. The best way to check is by looking at samples before you order a lot. Here is how you can check samples from your manufacturer:

-

Measure the sample to check the size.

-

Look at the stitching and how it is made.

-

Feel the rib knit fabric and check the finish.

-

Try on the clothing to see if it fits well.

-

Write down your thoughts and share them with the manufacturer.

Batch Testing

Consistency is important in every batch of rib fabric clothes. Manufacturers use checks during production. They test samples from each batch to make sure the rib knit fabric stretches right. They also check if the clothes match your standards. Asking for prototypes before making a lot helps you find problems early. These steps keep your clothing line strong and trusted.

Tip: Always ask for a sample before you order a lot. This helps you avoid problems and keeps your brand safe.

If you focus on quality checks and consistency, your rib knit clothes will stand out. Customers will see the difference, and your brand will get stronger.

Customization Options

When you choose a rib knit sweater manufacturer, you want your clothing to stand out. Customization gives your brand a unique voice. You can pick the look, feel, and message for your rib fabric clothing. Let’s see how you can make your sweaters special.

Design Flexibility

You want your rib fabric clothing to match your brand’s style. Good manufacturers give you lots of choices. They use advanced knit technology to help you test new ideas fast. Some, like Knitup, use real-time design tools. You can see your rib knit fabric ideas come to life before you order. Little Good Knits lets you start with just 50 pieces. This helps you try new rib fabric designs without spending too much.

-

You can test patterns and colors quickly.

-

You can change your rib fabric clothing as trends shift.

-

You waste less material, which helps the planet.

Pattern Choices

Patterns make your rib fabric clothing unique. You can pick from classic rib knit, wide rib, or even mix rib fabric with other knit styles. Some manufacturers offer advanced knitting techniques. This means you can create new textures and styles for your clothing. You can also add finishing touches, like special trims or buttons, to make your rib fabric clothing pop.

Color Selection

Color sets the mood for your rib fabric clothing. You want shades that match your brand. Top manufacturers offer a wide range of colors for rib knit fabric. You can choose bold, bright, or soft tones. This helps your clothing line stay fresh and on trend. You can even match colors to the season or your latest branding campaign.

Tip: Ask for a color swatch book. This helps you see and feel the rib fabric colors before you decide.

Here’s a quick look at the most popular customization options brands want:

|

Customization Options |

Description |

|---|---|

|

Patterns |

Unique designs and styles for rib fabric clothing. |

|

Sizes |

Options for all body types. |

|

Colors |

Many color choices for rib knit fabric. |

|

Finishing Touches |

Custom details for a polished look. |

|

Advanced Knitting Techniques |

New textures and styles for rib fabric clothing. |

|

Eco-friendly Materials |

Sustainable rib fabric for green brands. |

|

Low Minimum Order Quantities |

Try new rib fabric clothing ideas with small runs. |

|

Clear Communication |

Easy talks with your rib knit sweater manufacturer. |

Branding Services

Branding makes your rib fabric clothing line memorable. You want customers to remember your name and style. The right manufacturer helps you build a strong brand with private label clothing and white label clothing services.

Private Label

Private label clothing lets you put your brand on rib fabric clothing. You control the design, fit, and message. The manufacturer handles the hard work. You get clothing that looks and feels like your own. Many manufacturers offer consulting to help you plan your rib fabric clothing line. They help you make samples and get your rib knit fabric just right. You can start small and grow as your brand gets bigger.

Packaging

Packaging is the first thing your customer sees. Good packaging makes your rib fabric clothing look high-end. Many manufacturers offer white label clothing packaging. You can add your logo, special tags, or eco-friendly bags. Some even help with look books, photos, and web design. This makes your branding strong from the start. You get a full-service partner for your private label clothing and white label clothing needs.

Here are some branding services you can expect:

|

Service Type |

Description |

|---|---|

|

Consulting Services |

Tools and advice for your private label clothing line. |

|

Development |

Help with samples and rib fabric choices. |

|

Production |

Many colors, fabrics, and styles for white label clothing. |

|

Look Book & Photography/Video |

Pro photos and videos for your branding. |

|

Web Design & Development |

Custom websites for your private label clothing. |

|

Full-service Apparel Manufacturing |

From idea to finished rib fabric clothing for white label clothing brands. |

Note: Strong branding and packaging help your rib fabric clothing stand out in a crowded market.

You want your rib knit sweater manufacturer to offer flexible design, lots of rib fabric choices, and full branding support. This helps your private label clothing and white label clothing line grow and succeed.

Sustainability Practices

You want your rib fabric clothes to be special for more than style. People today care about how clothes are made. They want brands that use eco-friendly ways and fair sources. If you pick a rib knit sweater manufacturer with good sustainability, people will trust your brand more.

Eco-Friendly Production

Rib fabric clothes can help the planet if you choose the right company. Many manufacturers now use smart ways to protect nature. Here are some eco-friendly things you should look for:

-

They try to make less waste when making rib fabric clothes.

-

They work to make less carbon in their factories.

-

They use natural and organic things like cotton, wool, and bamboo.

-

They use safe dyes and finishing to stop pollution.

-

They use recycled fibers in rib fabric clothes, like wool, cotton, polyester, and cashmere.

-

They use packaging that can be recycled or breaks down easily.

When you ask about these things, you show you care about the earth. This also helps your rib fabric clothes attract shoppers who care about the planet.

Sustainable Materials

You want your rib fabric clothes to use earth-friendly materials. Many companies make sweaters from 100% organic cotton. Natural, recycled, or upcycled fabrics make rib fabric clothes better for the planet. These choices help your brand look green. You can ask your manufacturer where they get their rib fabric and knit materials. If they use organic or recycled fibers, your clothes will hurt the earth less.

Certifications

Certifications prove your rib fabric clothes meet high standards. They show your manufacturer follows strict rules for the planet. Here are some important certifications to look for:

|

Certification |

Description |

|---|---|

|

GCS |

Good Cashmere Standard: animal care and protecting nature. |

|

GOT |

Global Organic Textile Standard: organic materials and nature safety. |

|

HIGG VFEM |

Protects the environment. |

|

OCS |

Organic Content Standard: uses organic materials. |

|

OEKO-TEX |

Product safety. |

|

RWS |

Responsible Wool Standard: animal care and land safety for wool. |

|

SFA |

Sustainable Fiber Alliance: animal care and land safety for cashmere. |

You can also ask about OCS and EU Ecolabel certifications. These show your rib fabric clothes use organic materials and follow tough nature rules.

Ethical Sourcing

You want your rib fabric clothes to come from fair and safe places. Ethical sourcing means workers are treated well and suppliers are honest. This helps your brand have a good name.

Supplier Relationships

Good supplier relationships matter for rib fabric and knit clothes. Companies that care about fair trade pay workers fairly and keep them safe. They support workers’ rights and help with health and learning. You can ask your manufacturer if they follow WRAP or GRS rules. These show they use recycled materials and treat workers right.

Transparency

Being open is important for rib fabric clothing brands. You want to know where your clothes come from and how they are made. Companies that share their process help you make better choices. People now want to see where products come from and know workers are treated well. Brands that are open about their rib fabric and knit ways build trust. If your manufacturer is open, you can show customers you care about people and the earth.

Tip: Ask your manufacturer for details about their rib fabric supply chain. Talking openly helps you keep your clothes fair and earth-friendly.

Production Capacity

When you pick a rib knit sweater manufacturer, check if they can make enough sweaters for you. Production capacity means how many sweaters they can make at once. This affects how quickly you get your clothes and how your brand grows. You want a partner who can handle small orders or big ones.

Order Volume

Minimum Quantities

Every manufacturer has a minimum order amount. Some want you to order at least 1,000 sweaters. This lets you try new knit styles without spending too much. If you want to test different designs, flexible minimums help you do that. You can start new knit clothing lines and see what your customers like.

Scalability

If your brand gets bigger, you need a manufacturer who can make more sweaters. Scalability means they can handle larger orders when you need them. Top manufacturers use smart systems to manage lots of sweaters. They help you go from small batches to big orders and keep the quality high. Here is how a top manufacturer helps brands grow:

|

Step |

Description |

|---|---|

|

Requirement Specification |

You fill out a form to choose fabrics, crafts, and styles. |

|

Rapid Sampling |

You get three free samples in three days to check quality and design. |

|

Production Optimization |

Engineers change your designs for better cost and quality. |

|

Efficient Manufacturing |

Bulk production finishes in 15–30 days, with video updates so you see every step. |

|

Global Delivery |

DDP shipping brings your sweaters to your door, making delivery easy. |

-

A North American store sold 50% more in six months after starting a custom knit line.

-

A European brand got 35% more repeat orders by making bulk mens sweaters with special knit designs.

Strong scalability helps your brand do well.

Tip: Ask your manufacturer how they handle bigger orders. This keeps your clothing line ready to grow.

A good manufacturer lowers the price per sweater when you order more. You save money and keep your clothes new for your customers.

Lead Times

Delivery Options

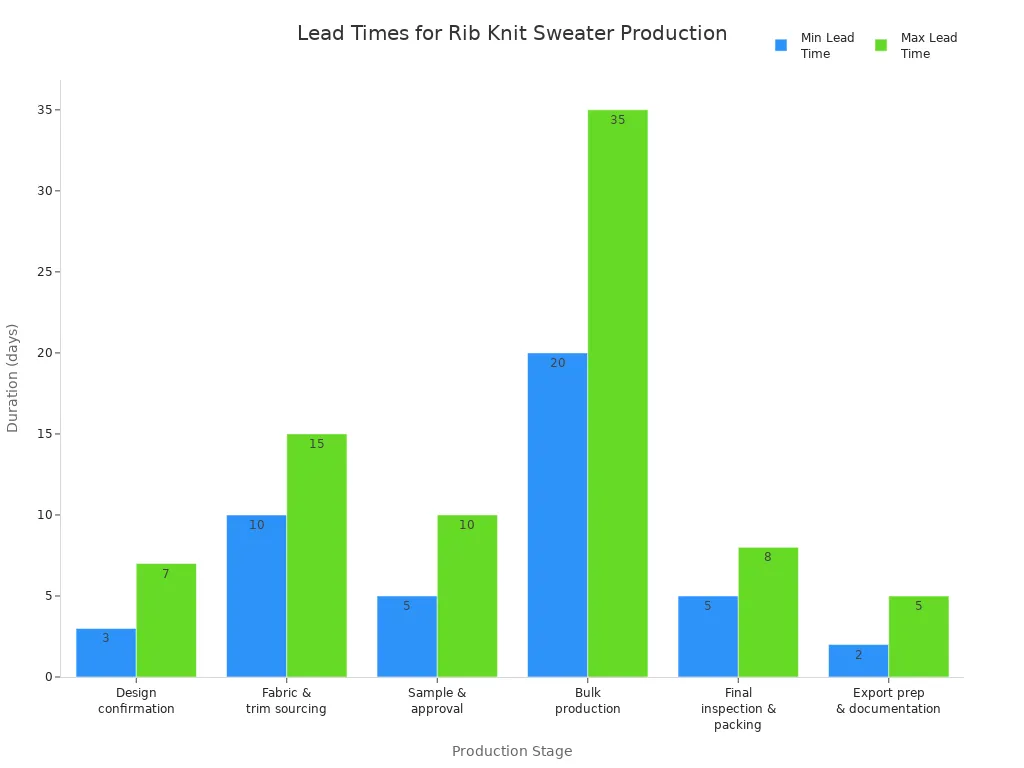

Lead times are important for every brand. You want your sweaters delivered on time. The best manufacturers give clear timelines for each step. Here is a look at common lead times:

|

Stage |

Duration |

|---|---|

|

Design confirmation |

3–7 days |

|

Fabric & trim sourcing |

10–15 days |

|

Sample & approval |

5–10 days |

|

Bulk production |

20–35 days |

|

Final inspection & packing |

5–8 days |

|

Export prep & documentation |

2–5 days |

Most manufacturers finish custom knitwear in 2–4 weeks. Regular knit clothing can take 4–8 weeks or longer. If you order from China, bulk orders usually take 45–75 days. Special knit styles may need up to 90 days.

Rush Orders

Sometimes you need sweaters fast. Manufacturers have special teams for rush orders. They work every day to meet your deadlines. You get your sweaters quickly and they still look good. Premium materials help with printing and embroidery, so your sweaters look great even when you need them fast. Good manufacturers promise rush orders and keep you updated.

-

Express shipping brings sweaters in 3–5 days.

-

Economy shipping takes 7–14 days.

Note: Always ask about rush order choices and delivery times. This helps you plan your launches and meet customer needs.

When you pick a manufacturer with strong production capacity, your clothing line stays flexible and ready to grow. You get quality sweaters on time, every time.

Communication & Reputation

When you pick clothing manufacturers, you want more than sweaters. You need a partner who talks clearly and has a good name in the clothing world. Here’s how you can check these things.

Responsiveness

You want your manufacturer to reply fast. Quick answers make you feel important. They help you fix problems and keep your clothing line moving.

Contact Channels

Good manufacturers give you many ways to talk. You can use email, phone, or instant messages. Some have online sites to track your orders. Good talking means you always know what is happening.

-

You get answers quickly.

-

You can share new design ideas.

-

You know who to call if there is a problem.

Updates

You want to know what is happening with your orders. Good manufacturers tell you when your order starts and when it ships. They let you know if there are delays. They also tell you about price changes and mistakes. This honesty helps you trust them.

Tip: Ask how often your manufacturer sends updates. Getting news often helps you plan your clothing launches.

Talking openly builds trust. When your manufacturer shares all news, you feel sure about their work. They listen to your ideas and use them to make your clothes better.

Industry Reputation

A good name means your manufacturer has helped other brands. You want proof they make good clothes and follow safety rules.

Reviews

See what other brands say about the manufacturer. Look for reviews about few mistakes, fair work, and good skills. Percival has only 0.3% mistakes and is known for fair work. Howlin is famous for hand-knitting and keeping old ways alive.

|

Manufacturer |

Strengths |

Defect Rate |

Price Range |

|---|---|---|---|

|

Percival |

Few mistakes, fair work, good skills |

0.3% |

$120+ |

|

Howlin |

Hand-knitting, real style, old ways |

N/A |

$60+ |

Recommendations

Ask other brands for advice. Visit the factory if you can. Look at the knitting machines and see if they are clean. Good manufacturers often sell to Europe and America, so check their history. Ask for papers that show they follow safety and quality rules.

|

Indicator |

Description |

|---|---|

|

Fiber Quality |

Uses new wool or strong cotton for tough clothes. |

|

Weight and Density |

Thick knits do not stretch or pill easily. |

|

Finishing Touches |

Well-sewn buttons, zippers, and labels show care. |

Check business licenses and quality papers too. Good manufacturers send samples fast, in 5-7 days. This shows they care about your clothing line and want you to do well.

Note: Good talking and a strong name help you build a clothing brand people trust.

Value & Pricing

When you choose a rib knit sweater manufacturer, you want to get the best value for your money. You need to look at more than just the price tag. Think about what you get for your investment. The right partner helps your clothing brand grow, keeps your customers happy, and supports your branding goals.

Overall Value

Service Quality

You want your clothing to look great and last a long time. Service quality matters a lot. Good manufacturers use strong rib knit fabric. This fabric can handle up to 1500 washes and still keep its shape. Plain fabrics wear out faster and lose their stretch. Rib knit feels soft and comfy. It works for many styles, especially in athleisure. You get sweaters that fit well and make your customers feel good.

Here are some things that add value:

-

The manufacturer understands your production needs. This helps you avoid wasting resources.

-

Machines that match your order size make operations smooth and save money.

-

Fast machines improve production speed and quality.

-

Energy-efficient machines and low maintenance costs help you save in the long run.

-

Rib knit fabric gives you durability and comfort for your clothing line.

Reliability

Reliability means you can trust your manufacturer to deliver on time and keep quality high. You want a partner who meets deadlines and keeps your clothing consistent. Reliable service helps you avoid delays and keeps your branding strong. If you sell private label clothing or white label clothing, you need sweaters that always look and feel the same. Customers will come back when they know your clothing is dependable.

Pricing Structure

Transparent Quotes

You should always ask for clear quotes. Transparent pricing helps you plan your budget and avoid surprises. Good manufacturers break down costs for you. They show you what you pay for materials, labor, and extra services. You can see how each part affects the final price of your clothing.

Here’s a table that shows how different factors impact cost and quality:

|

Factor |

Impact on Cost |

Impact on Quality |

|---|---|---|

|

Raw Material Prices |

High |

High |

|

Labor Costs |

Medium |

Medium |

|

Production Complexities |

High |

High |

|

Yarn Type |

Up to 86% |

High |

Cost vs. Quality

You want to balance cost and quality. High-quality materials make your clothing last longer and look better. Sometimes, market prices for yarn and other materials go up and down. Manufacturers must balance quality and cost to stay competitive. If you choose private label clothing or white label clothing, you need to make sure your branding matches your budget. You want clothing that feels good and looks great, but you also need prices that work for your business.

Here are some tips to help you decide:

-

Check the quality of materials before you order.

-

Ask about market price changes for raw materials.

-

Make sure your manufacturer can keep quality high even when costs change.

-

Compare quotes from different manufacturers to find the best value for your clothing and branding needs.

Tip: Always ask for samples before you place a big order. This helps you check quality and make sure you get the best value for your private label clothing or white label clothing line.

When you focus on value and pricing, you build a clothing brand that stands out. You get reliable service, strong branding, and sweaters your customers love.

You want your clothing brand to stand out. Picking the right rib knit sweater manufacturer helps you get clothing with great quality. Make a checklist with all the important steps. Look at quality, design, and how the manufacturer treats people and the planet. Ask for samples and talk with different companies. Compare their clothing and see which one fits your needs. When you focus on quality, your clothing line grows stronger. Start now and choose a partner who cares about your clothing and your brand’s future.

FAQ

What is the minimum order quantity for rib knit sweaters?

Most manufacturers want you to order at least 50 or 100 sweaters. Some let you buy fewer if you ask. Always check their minimum order rules before you start.

Can I request samples before placing a bulk order?

Yes, you can get samples first. Most companies send samples so you can see the quality and fit. This helps you know what you will get before you buy a lot.

How long does production take for custom rib knit sweaters?

How long it takes depends on your order and design. Most orders take between 2 and 6 weeks. If you need sweaters quickly, some companies offer rush service.

What customization options do manufacturers offer?

You can pick patterns, colors, sizes, and labels for your sweaters. Some companies help with packaging and branding too. Ask them for a list of all the ways you can customize.

Are sustainable materials available for rib knit sweaters?

Many companies use organic cotton, recycled fibers, and safe dyes. You can ask for certificates like GOTS or OEKO-TEX to make sure your sweaters are eco-friendly.

How do I communicate with my manufacturer during production?

You can talk by email, phone, or online chat. Good companies give updates and answer your questions fast. Clear talking helps your project go smoothly.

What should I look for in a manufacturer’s reputation?

Read reviews and see what other clients say. Check if they have won awards or have happy customers. If you can, visit their factory to see how they work.