Choosing the best odm sweater supplier can help your business do well. You need a sweater maker who has good experience. They should have a strong list of past work. They must be able to make custom sweaters. Many big brands pick suppliers very carefully. This helps them lower mistakes and make better sweaters. Good supplier choices can help your business grow and make better products.

Practices | Impact on Quality | Business Success |

|---|---|---|

Quality assurance, training, technology | Fewer defects, better products | Higher sales, strong reputation |

You should always look up facts before you pick a sweater supplier. Good choices come from knowing the truth.

Key Takeaways

Picking the best ODM sweater supplier helps your business do well and makes your products better.

Find suppliers who have lots of experience and a good portfolio. This helps you trust them.

Customization lets you make special sweaters that match your brand.

Make sure the supplier follows rules and has certifications. This shows they use good materials and act fairly.

Talking clearly with your supplier stops mistakes and keeps orders moving.

Learn how prices and payments work so you can plan your money.

Ask for samples to check quality before you buy a lot.

Stay with your supplier for a long time to get more help and better products.

What Is an ODM Sweater Supplier

When you search for a sweater maker, you will find many types. One main type is the odm sweater supplier. This kind of company makes sweater designs and produces them for brands. You can pick from their designs or ask for small changes. Many brands use odm sweater manufacturing to save both time and money.

ODM vs. OEM Explained

You might wonder how odm and oem are not the same. These words show how a clothing manufacturer works with you.

Here is a table that shows the main differences:

Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

Design Ownership | Brand provides designs and specifications | Manufacturer creates and designs products |

Customization | Limited to brand’s specifications | Offers pre-designed items with customization options |

Production Responsibility | Brand is responsible for design and specifications | Manufacturer handles design and production |

Lead Times | Typically longer due to design process | Generally shorter as designs are pre-made |

Costs | May vary based on design complexity | Often lower due to pre-designed items |

With oem, you give your own designs to the sweater maker. You control all the details, but it takes longer and costs more. With odm, the manufacturer owns the designs. You choose from their styles and get sweaters faster. You also pay less because the designs are already made.

You can see more differences in this table:

Characteristic | ODM Supplier | Other Supplier Types |

|---|---|---|

Ownership of Intellectual Property | Supplier owns the design and can sell to others | Buyer retains design ownership |

Limited customization available | More extensive customization options | |

Speed to Market | Fast due to existing designs | Slower as new designs need to be developed |

Cost-Effectiveness | Lower costs due to economies of scale | Potentially higher costs |

Control over Production | Limited visibility and control | More control over production processes |

Tip: If you want to sell new sweater styles fast, odm sweater manufacturing helps you get to the market quickly.

Why Supplier Choice Matters

Choosing the right odm sweater supplier helps your business do well. The supplier you pick affects your product quality, speed, and brand image. Some clothing makers use new materials and eco-friendly choices. These things help you get customers who care about the earth.

Here is a table that shows how supplier features can help your business:

Evidence | Explanation |

|---|---|

Innovative materials and sustainable options | Suppliers that provide these can enhance product offerings and attract eco-conscious consumers, improving competitiveness. |

Investment in traceability and regenerative fibres | This distinguishes market leaders, especially with tightening global regulations on sourcing and transparency. |

3D knitting and virtual sampling | These technologies reduce waste and turnaround times, enabling brands to respond quickly to market demands, thus enhancing competitiveness. |

You should pick a sweater maker that uses new technology. This helps you keep up with trends and meet what customers want. The right clothing manufacturer can help you stand out in a busy market.

Key Criteria for Choosing an ODM Sweater Supplier

Picking the right odm sweater supplier helps your brand grow strong. You need to think about a few important things before you choose. This part will show you the most important factors.

Experience and Portfolio

Years in Business

Check how long the sweater maker has worked in the industry. If they have many years, they know the market well. They can solve problems and make good sweaters. Long experience means they meet high standards and keep up with fashion changes.

Client List

Ask for a list of clients the clothing maker has helped. Big brands trust suppliers who always give good products. If you see famous names, the supplier has a good reputation. You can ask for references to learn about their trustworthiness and quality.

Tip: A long client list shows the sweater maker has strong skills. They can handle big orders or low moq sweater manufacturer requests.

Product Quality and Control

Sample Reports

Ask for sample reports from the supplier. These reports show the quality of their work. You can see details about materials, stitching, and finishing. Good sweaters come from strict standards and careful product customization. Sample reports help you decide if the sweater maker fits your needs.

Manufacturing Process

Find out about the manufacturing process. Ask how the clothing maker checks quality at every step. Good suppliers use checks to find problems early. They test materials and look at finished sweaters. This makes sure you get sweaters that meet your needs every time.

Criteria | Description |

|---|---|

Design Originality and Intellectual Property Protection | Making sure designs are original and protected helps your brand compete. |

Capability for Trend Adaptation | Changing quickly to new fashion trends keeps your brand popular. |

Specialization in ODM Fabric Innovation | Picking a maker who uses new fabrics makes your sweaters special. |

Options for Custom Prints | Custom prints and special choices help you match what customers want. |

Customization Options

Design Flexibility

You need a sweater maker who lets you change designs. You can pick colors, patterns, and styles for your brand. Product customization helps you make sweaters that stand out. Many odm suppliers offer embroidery, screen printing, and tie-dye. These choices help you meet different customer needs.

Embroidery for strong designs

Screen printing for bright, affordable options

Tie-dye for special patterns

Specialty printing like DTF and DTG

Custom tags and labels for your brand

Technology Used

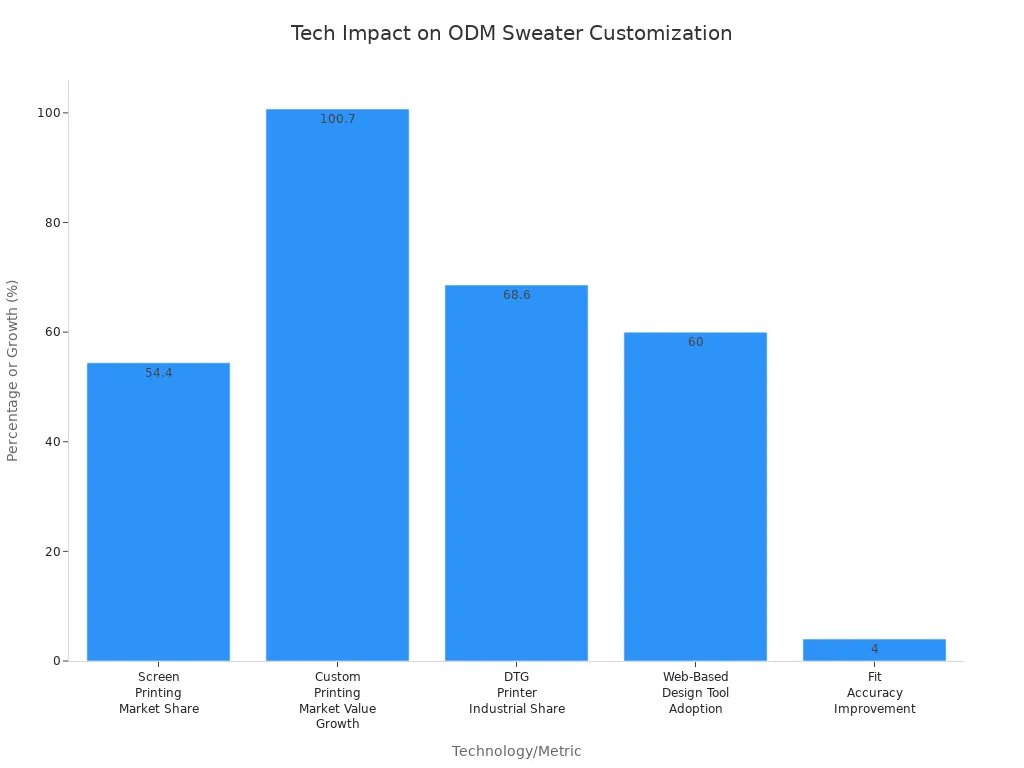

New technology makes customizing sweaters faster and easier. Many clothing makers use online design tools, body scanning, and digital printing. These tools help sweaters fit better and lower returns. DTG printing makes production 25% faster. Screen printing is very popular for custom sweaters in 2024. Technology also lets you order small amounts, so you can work with a low moq sweater manufacturer.

Customization Option | Description |

|---|---|

Fabric Choices | You can pick 100% cotton, organic cotton, or blends. |

Personalization Techniques | You can choose embroidery, screen printing, tie-dye, or distressing. |

Design Consultation | Work with experts to plan your design and add brand ideas. |

Proofing | Get a sample in 7 days to check and approve. |

Custom Tags and Labels | Use special labels and tags to show your brand. |

Pick an odm sweater supplier who uses new technology and gives many customization choices. This helps you make great sweaters that fit your brand and what people want.

Compliance and Certifications

When you pick an odm sweater supplier, check their compliance and certifications. These show if the sweater manufacturer follows the rules and acts fairly. Certifications help you know the clothing manufacturer uses safe materials and treats workers right.

Industry Standards

A good sweater manufacturer will have certifications that prove they follow strict rules. These certifications also show they care about the planet and their workers. Look at the table below to see some important certifications:

Certification Name | Purpose | Required Certification Level |

|---|---|---|

Cradle to Cradle Certified | Encourages improvement in sustainability across materials and products. | Products must meet all criteria for the certification level and those below it. |

Green Button | Ensures sustainability and social responsibility in textiles. | Requires compliance with strict environmental and social standards across the entire supply chain. |

EU Ecolabel | Highlights textiles meeting strict environmental standards. | Manufacturers must meet stringent criteria for sustainable sourcing, hazardous substance reduction, and more. |

B Corporation | Recognizes companies prioritizing social and environmental responsibility. | Must earn a minimum score of 80 on the B Impact Assessment covering various impact areas. |

Fair Wear Foundation | Advocates for workers’ rights in the apparel industry. | Works with brands to improve labor conditions; does not issue traditional certification. |

Higg Index | Assesses and improves sustainability performance across the supply chain. | Provides tools for evaluating environmental, social, and labor impacts. |

Bluesign | Promotes safe chemical use and responsible practices. | Focuses on high safety standards and responsible resource management. |

STeP by OEKO-TEX | Fosters sustainable production in textile and leather facilities. | Evaluates the entire production process, including chemical management and social responsibility. |

ZDHC | Promotes elimination of harmful chemicals in supply chains. | Not a certification but integrates standards for safer chemical management. |

OEKO-TEX Eco Passport | Certifies chemicals used in textile production are safe. | Requires rigorous verification against harmful substances and compliance with safety standards. |

Ask your sweater manufacturer to show proof of these certifications. This helps you make sure your custom sweaters are safe and high quality. If you want to sell in places with strict rules, these certifications are very important.

Ethical Practices

Ethical practices are just as important as quality. You want a supplier who treats workers well and cares about the earth. When a clothing manufacturer builds long partnerships, you get better results and fewer problems.

“It’s about making a place where suppliers can share worries and work together. The project changed things by focusing on HRDD and buying practices.”

Being open builds trust: Both buyer and supplier said sharing costs and plans helped them work better together.

“Now, everyone is more open, and all sides want to work together to make things better.”

Look for a sweater manufacturer who values trust and honest talk. This helps you avoid problems with worker rights and keeps your supply chain strong. Good ethics also help your brand look good and bring loyal customers.

Communication and Support

Good communication and support help you work well with your odm sweater supplier. You need clear updates and quick answers to your questions. Good communication helps you fix problems fast and keeps your sweater orders on track.

Language Skills

Check if your supplier has staff who speak your language well. This makes it easier to talk about designs, quality, and cost. If you do not understand each other, mistakes can happen in your sweater orders. Many top sweater manufacturers use English, but you should always check their skills first.

Customer Service

Good customer service means you get help when you need it. You want a clothing manufacturer who answers emails and calls fast. If a supplier takes too long or gives unclear answers, you may have delays and extra costs.

A brand once waited five days for a reply about an order. The supplier gave unclear answers about fabric quality. The order came 14 days late and missed the season. This shows why fast and clear customer service matters.

Ask your sweater manufacturer how they handle support. Try sending questions before you order. See how fast and clear their answers are. This helps you avoid problems with moq, delivery, and quality.

Communication Channel | Benefits |

|---|---|

In-person meetings | Build stronger relationships and help talk about progress and problems. |

Video chats | Add a personal touch and help build trust. |

Emails and text messages | Good for regular updates, but less personal. |

Standardized processes | Help stop mistakes, especially with many suppliers. |

Tip: Talking openly about how things work helps you and your supplier work better. Paying on time and clear payment rules also build trust.

Pricing and Terms

You need to understand pricing and terms before you pick a sweater manufacturer. This helps you control costs and avoid surprises. A good odm supplier will give you clear prices and fair payment choices.

Cost Structure

Most sweater manufacturers use bulk pricing. The more you order, the less you pay for each sweater. This helps you plan your budget and control costs. See the table below for a typical pricing structure:

Quantity | Discount Rate |

|---|---|

1-50 pieces | Standard wholesale price |

51-200 pieces | 5-10% discount |

201-500 pieces | 15-20% discount |

500+ pieces | Custom pricing based on negotiation |

Bulk pricing means you pay less for each sweater when you order more.

Many suppliers give extra discounts, like 3–10% off for bigger orders.

You can ask for special prices for very big or repeat orders.

Ask your clothing manufacturer for a full price list. Make sure you know the moq and how discounts work for custom orders.

Payment Options

Sweater manufacturers use many ways to get paid. You should pick the one that works best for your business. Here are some common options:

Letter of Credit (L/C): A safe way to pay, often for new partners.

T/T (Telegraphic Transfer): You pay some before and the rest after production.

Open Account: You pay later, usually with trusted suppliers.

Documentary Collections: You get papers after you pay or accept the bill.

Cash in Advance (CIA): You pay before the sweater manufacturer starts work.

Consignment: You pay after you sell the sweaters.

Net Terms: You pay within a set time after getting the bill.

CAD (Cash Against Documents): You pay when you get the shipping papers.

Revocable or Irrevocable L/C: Different levels of safety for letters of credit.

Confirmed or Unconfirmed L/C: Shows how safe the payment is.

Talk with your odm supplier about payment terms before you order. Clear terms help you avoid delays and keep your sweater business running well.

Lead Times and Delivery

Choosing the right lead times and delivery options helps you keep your business running smoothly. You want your sweaters to arrive on time and in good condition. A reliable sweater manufacturer will give you clear timelines and flexible shipping choices. This section explains what you need to know about production and delivery.

Production Timeline

You should always ask your sweater manufacturer about their production timeline. This tells you how long it takes to make your custom sweaters from start to finish. Most suppliers break the process into steps. Each step has its own time frame.

Here is a table that shows the average lead times for ODM sweater production:

Stage | Lead Time |

|---|---|

Sample Production | 7-10 days |

Mass Production (100-500) | 15-25 days |

Mass Production (1000+) | 25-40 days |

Material Sourcing | +5-10 days (if applicable) |

Air Freight | 7-10 days |

Sea Freight (US/Europe) | 25-35 days |

Sea Freight (Southeast Asia) | 15-25 days |

Sea Freight (Australia) | 20-30 days |

Express Courier | 5-7 days |

Total Process | 30-60 days |

You can see that sample production usually takes about one week. Mass production for small orders (100-500 pieces) takes about two to three weeks. Large orders (over 1000 pieces) may take up to forty days. If your custom design needs special materials, add five to ten more days for sourcing.

Tip: Always check if your sweater manufacturer can meet your deadline, especially for seasonal collections or special events.

Shipping Methods

After production, you need to choose how your sweaters will ship. The shipping method affects both cost and delivery speed. A good odm sweater supplier will offer several options to fit your needs.

Here are the most common shipping methods:

Air Freight: Fast and reliable. Your sweaters arrive in about 7-10 days. This works well for urgent orders or small batches with low moq.

Sea Freight: Best for large orders. Delivery to the US or Europe takes 25-35 days. Southeast Asia takes 15-25 days. Australia takes 20-30 days. This method costs less but takes longer.

Express Courier: The fastest option. Delivery takes only 5-7 days. This works for samples or very small custom orders.

Combined Shipping: Some suppliers use both air and sea freight to balance speed and cost.

You should talk with your sweater manufacturer about the best shipping method for your order size and budget. Ask if they provide tracking and insurance. This protects your sweaters from loss or damage during transit.

Shipping Method | Speed | Cost | Best For |

|---|---|---|---|

Air Freight | 7-10 days | Higher | Urgent or small orders |

Sea Freight | 15-35 days | Lower | Large or bulk orders |

Express Courier | 5-7 days | Highest | Samples, small orders |

Note: Always confirm the shipping timeline with your supplier. Delays can happen due to customs or weather. Good communication helps you plan ahead and avoid surprises.

You want a sweater manufacturer who gives you clear updates about production and delivery. This helps you manage your inventory and keep your customers happy. Reliable lead times and flexible shipping make your custom sweater business strong.

Research Potential Suppliers

You should look up information about suppliers before picking a custom sweater manufacturer. This helps you find the best one for your brand. It also helps you avoid expensive mistakes. You can use the internet or go to events to find good partners for your business.

Finding Custom Sweater Manufacturers

Online Directories

Online directories help you find a sweater manufacturer fast. These websites let you search by where they are, what they make, and what they do. You can see many choices in one spot. Some well-known directories are:

Alibaba: A big B2B website with many custom sweater manufacturers.

Maker’s Row: Connects you to American factories for custom work.

Global Sources: Has lots of suppliers for sweater sourcing.

You can sort by minimum order, certifications, and what they can make. This helps you find a supplier that matches what you need.

Trade Shows

Trade shows let you meet sweater manufacturers in person. You can look at samples, check the quality, and ask questions right away. Some big trade shows are MAGIC Las Vegas and Texworld USA. These events help you trust the supplier and start good business deals.

Method | Strengths | Weaknesses |

|---|---|---|

Trade Shows | Meet people, check products, talk about deals, see quality | You may need to travel and spend time |

Online Directories | Easy search, lots of choices, saves time | You cannot check things right away or meet people |

Tip: Try both online directories and trade shows to learn more about the custom sweater manufacturer market.

Making a Supplier List

Industry Recommendations

You should ask people in your business for advice. Many brands talk about their custom sweater manufacturers. These tips help you avoid problems and find good suppliers. ODM suppliers can help you from design to delivery.

ODM suppliers often have good fabric choices.

They help you with every part of making sweaters.

Industry tips save you time and lower your risk.

Initial Screening

After you get some names, you need to check each sweater manufacturer. Look at their business licenses and certifications. Make sure they can ship to your country. Ask how long samples take and if they have flexible minimum orders. Ask for a price list so you know all the costs.

You can use this checklist to help you:

See if they ship to Europe or America.

Ask how long samples take to make.

Check if you can order small amounts.

Ask for a clear price list.

Think about visiting to see how they work and talk.

Note: Careful checking helps you make a list of good suppliers for your custom sweaters.

Assessing Supplier Capabilities

OEM/ODM Experience

You want a sweater manufacturer with lots of OEM and ODM experience. This means they can make custom and ready-made sweaters. Look for suppliers who do many things, like CMT, CMPT, and one-stop-shop services. These suppliers usually make good sweaters and meet your needs.

Assessment Method | Description |

|---|---|

They check quality for every sweater. | |

On-Time delivery | They make and ship sweaters on time. |

Diverse service | They offer CMT, CMPT, OEM, ODM, and one-stop-shop. |

Sustainability | They use eco-friendly materials and good practices. |

Customer satisfaction | They work with you to get what you want. |

End-to-End Control

End-to-end control means the custom sweater manufacturer handles every step. This makes sweaters more consistent and better quality. You should ask how they check quality at each step.

Stage of QC | Description |

|---|---|

Inbound Inspection | |

Inline QC Checks | Looks at stitching, seams, and patterns. |

Finishing Inspection | Presses and checks for wrinkles, stains, and size. |

Final QC Testing | Tests for color staying, pilling, and strength. |

Corrective Actions | Fixes any problems they find. |

Good end-to-end control helps you get sweaters that always meet your standards.

You should always look up suppliers, make a list, and check what they can do. This helps you find a custom sweater manufacturer who fits your needs and makes high-quality sweaters.

Vetting and Shortlisting ODM Sweater Suppliers

When you want to pick the best custom sweater manufacturer, you need to check and narrow down your choices. This step helps you avoid mistakes and pick a partner who fits your needs.

Requesting Samples

Sample Quality

You should always ask for samples before making a big order. Samples let you see the quality, look, and feel of the sweaters. You can check if the stitching is neat and if the fabric feels nice. If the sample is good, you can trust the custom sweater manufacturer to make good sweaters.

Samples let you test the product before buying a lot.

You can find problems early and ask for changes.

Good samples help you trust the supplier.

Tip: Use what you learn from samples to set clear rules for quality in future orders.

Timelines

Ask the sweater manufacturer how long it takes to make and send samples. Fast sample delivery means the supplier is organized and cares about your time. If samples come late, your main order might be delayed. Always check if the supplier can meet your deadlines for special or seasonal sweaters.

Checking Reviews and References

Online Feedback

Look for online reviews about each custom sweater manufacturer. Reviews from other buyers show if the supplier is reliable and makes good sweaters. You can find reviews on business websites or trade pages. Good reviews mean the supplier has a good reputation.

Factory Visits

If you can, visit the factory in person. You will see how the sweater manufacturer works and checks quality. You can look at the machines, meet the workers, and watch how sweaters are made. Factory visits help you find problems and make sure the supplier is safe and fair.

Description | |

|---|---|

Research | Look up the manufacturer’s experience, skills, and reputation. |

Audit Reports and Certifications | Ask for audit reports to make sure they follow rules for quality and fairness. |

References | Ask for past client contacts and talk to them about their experience. |

Payment Terms | Make sure payment rules are clear and fair, and do not pay everything up front. |

Inspections | Check sweaters at different steps, or hire someone to inspect for you. |

Evaluating Product Range

Styles and Designs

Check the styles and designs each custom sweater manufacturer offers. You want a supplier who can make sweaters that match your brand’s look. Ask for a catalog or pictures of their past work. This helps you see if they follow trends and have enough choices.

Brand Alignment

Make sure the supplier understands your brand. The right sweater manufacturer will help you make sweaters that fit your brand’s style and values. Talk about your ideas and see if the supplier can change designs for you. When your supplier matches your brand, your sweaters will stand out.

Note: Always ask about minimum order amounts, how much they can make, and payment rules before you choose.

You can use this checklist to help you check and narrow down suppliers:

Ask how long they have been in business and what they do best.

Ask about minimum order amounts and how much they can make.

Ask for price estimates and clear payment rules.

Learn about their quality checks and certifications.

Picking the right custom sweater manufacturer takes time, but careful checking helps you build a strong business.

Negotiating and Finalizing with Custom Sweater Manufacturers

When you get close to finishing a deal with a custom sweater manufacturer, you need to make sure everything is clear. You should test the supplier’s work before making big plans. This helps you avoid mistakes and build a good business friendship.

Contract Essentials

Terms and Conditions

Always check the contract rules before you sign anything. These rules tell you and the custom sweater manufacturer what to do. Look for things like how you pay, when sweaters arrive, and what happens if there are problems. The contract should say what quality your sweaters must have. If you want special boxes or tags, add these to the contract.

A simple checklist for contract rules:

How and when you pay

When you get your sweaters

What quality you want

Details about boxes and tags

What to do if you return sweaters

What happens if sweaters are late

Tip: Ask questions if you do not get something in the contract. Clear rules help keep your business safe.

Intellectual Property

You need to keep your designs and brand safe. Ask the sweater manufacturer how they protect your ideas. The contract should say who owns the designs. It should also say if the supplier can use your designs for other people. If you want your designs to stay secret, add a non-disclosure agreement. This keeps your ideas safe from being copied.

Intellectual Property Checklist | Why It Matters |

|---|---|

Design ownership | Keeps your brand special |

Non-disclosure agreement | Keeps your ideas secret |

Trademark use | Stops others from copying |

Trial Orders

Setting Expectations

Start with a small order before you buy a lot. This lets you see if the custom sweater manufacturer is good for you. Tell the supplier what you want for quality, delivery, and service. Write down your needs so everyone knows what to do.

Make clear goals for the small order

Share your list for checking quality

Agree on when you get your sweaters

Note: A small order helps you trust the supplier and find problems early.

Performance Metrics

You should check how the supplier does during the small order. Use easy ways to see if the sweater manufacturer meets your needs. Watch for things like if sweaters come on time, if they are made well, and if the supplier answers fast.

Metric | What to Check |

|---|---|

On-time delivery | Did the sweaters come on time? |

Quality | Are the sweaters made well? |

Communication | Did the supplier answer fast? |

If the supplier does a good job, you can order more sweaters. If not, you can look for a better supplier.

Common Mistakes and Red Flags

Ignoring Quality Assurance

You should never ignore quality assurance when choosing a supplier. Quality assurance means checking every step to make sure your sweaters meet your standards. If you skip this, you might get sweaters with loose threads, uneven stitching, or poor fabric. These problems can hurt your brand and cost you money.

Here are some common mistakes businesses make when picking a supplier:

Not checking the manufacturer’s experience. You need a team that knows how to make sweaters well.

Ignoring the minimum order quantity (MOQ). If you do not ask, you might end up with too many sweaters.

Skipping sample approval. Always ask for samples before you order a large batch.

Poor communication. You must talk clearly with your supplier to avoid mistakes.

Not asking about lead time and flexibility. You should know how long it takes to get your sweaters and if the supplier can handle changes.

You should also ask about the training and skills of the supplier’s team. If the team does not have good training, you might see more mistakes in your sweaters.

Tip: Always request third-party audits or quality checks. This helps you spot problems before they reach your customers.

Poor Communication

Poor communication can cause big problems in your sweater orders. If you do not share clear details, your supplier might not understand what you want. This can lead to wrong colors, sizes, or even late shipments.

You should look for these warning signs:

The supplier does not answer your emails or calls quickly.

You get unclear or confusing answers.

The supplier does not confirm your requests in writing.

If you see these signs, you might face delays or get sweaters that do not match your needs. Good communication helps you solve problems fast and keeps your business running smoothly.

Note: Always keep a record of your talks with the supplier. This helps you avoid confusion and proves what you agreed on.

Missing Certifications

Missing certifications is a big red flag when you choose a sweater manufacturer. Certifications show that the supplier follows safety, quality, and ethical rules. If a supplier cannot show proof, you should be careful.

Watch out for these issues:

The factory refuses third-party audits or does not share reports.

The supplier cannot show documents for compliance certifications.

The supplier uses unverified subcontractors.

You should always ask for copies of certifications like OEKO-TEX, BSCI, or GOTS. These documents help you trust that your sweaters are safe and made fairly.

Callout: Missing certifications can lead to legal trouble or damage your brand’s reputation. Always check before you order.

Price-Only Decisions

You might think picking the lowest price is the best way to save money. This is a common mistake when choosing an ODM sweater supplier. Price matters, but it should not be your only reason for picking a supplier. Low prices can hide problems that cost you more later.

When you focus only on price, you may face these risks:

Poor quality sweaters that hurt your brand

Delays in production or shipping

Hidden fees or extra costs after you order

Lack of support or slow communication

Tip: Always compare what you get for the price. Look at quality, service, and reliability, not just the number on the invoice.

Here is a simple table to help you compare suppliers:

Factor | Low Price Supplier | Balanced Supplier |

|---|---|---|

Quality | Often lower | Consistent |

Communication | Slow or unclear | Responsive |

Delivery | Unreliable | On time |

Support | Limited | Helpful |

You should ask yourself, “Will this supplier help my business grow, or will I spend more fixing problems?” A balanced choice saves you time and money in the long run.

No Sample Requests

You need to see and feel a sample before you place a big order. Skipping this step is a big mistake. Samples show you the real quality of the sweaters. They help you check the fabric, stitching, and fit.

If you do not ask for samples, you risk:

Getting sweaters that do not match your needs

Finding mistakes too late to fix them

Wasting money on products you cannot sell

Alert: Never skip the sample step, even if you trust the supplier. A good supplier will always send you a sample.

Here is a checklist for sample requests:

Ask for a sample of the exact style and fabric

Check the stitching, color, and size

Test the sweater for comfort and durability

Give feedback and ask for changes if needed

Samples help you set clear standards. They also show the supplier that you care about quality.

Vague Contracts

A clear contract protects you and your business. If your contract is vague or missing details, you may face problems. You need to know what to expect from your ODM sweater supplier.

Vague contracts can lead to:

Confusion about payment terms

Disputes over delivery dates

No clear rules for quality or returns

Trouble protecting your designs

Note: Always read the contract carefully. Ask questions if something is not clear. Get everything in writing.

A good contract should include:

Payment terms and deadlines

Delivery schedule and shipping method

Quality standards and inspection rules

Return and refund policies

Intellectual property protection

You should keep a copy of every contract. This helps you solve problems quickly if something goes wrong.

Building Long-Term Supplier Relationships

You want your sweater business to grow and last. You should work on having a good relationship with your supplier. A strong partnership helps you fix problems and make better sweaters. It also keeps your customers happy. When you work together for a long time, you reach your goals and stand out in the market.

Clear Communication

Talking clearly is very important for a good partnership. You should tell your supplier what you need and expect. Share your ideas for new sweater styles and ask questions about how they work. Good communication helps you avoid mistakes and builds trust.

Have regular meetings to talk about orders and feedback.

Use easy words and write down important details.

Ask for updates about making and shipping sweaters.

Tip: If something goes wrong, tell your supplier quickly. Fast action keeps your partnership strong and helps you fix problems before they get bigger.

Regular Audits

You need to check your supplier’s work often. Audits help you see if the supplier makes good sweaters and follows rules. You can visit the factory or hire someone to look at the sweaters.

Audit Type | What You Check | How Often |

|---|---|---|

Quality Audit | Stitching, fabric, finishing | Every order |

Compliance Audit | Worker safety, certifications | Twice a year |

Sustainability Audit | Eco-friendly practices | Once a year |

Regular audits help you keep your partnership healthy. They show your supplier that you care about quality and the planet. This makes your relationship stronger and helps you avoid surprises.

Continuous Improvement

You should always try to make your partnership better. Ask your supplier for ways to improve sweaters or work faster. Share what your customers say and solve problems together. You can set goals for quality, delivery, and eco-friendly choices.

Look at your results after each order.

Make new goals for the next season.

Try new materials or ways of making sweaters with your supplier.

Note: Always try to get better so you can follow trends and make customers happy. Working together helps your partnership grow stronger.

Long-term partnerships help you reach your business goals. You get better sweaters, faster service, and more help. When you build a strong relationship, you make a team that cares about your success. You also help your supplier use better and greener ways to make sweaters. This makes your business stronger and helps your brand last a long time.

You can pick the best ODM sweater supplier if you follow easy steps. First, do research to find suppliers that fit what you need. Then, check how much experience they have and if their sweaters are good. Look at what kinds of changes they can make for you. Talk with them often and check their work to build trust. Doing research helps you not make mistakes and find a partner who helps your business grow.

Start looking for your supplier now. Take action and make your sweater brand stronger!

FAQ

What does ODM mean in sweater manufacturing?

ODM stands for Original Design Manufacturer. You choose from the supplier’s designs. You can ask for small changes. This helps you get sweaters faster and often at a lower cost.

How do you check the quality of an ODM sweater supplier?

You should ask for samples and quality reports. You can visit the factory or hire a third-party inspector. Good suppliers share test results and let you check their work.

What is MOQ and why does it matter?

MOQ means Minimum Order Quantity. It tells you the smallest number of sweaters you must order. You need to know this to plan your budget and avoid buying too much.

Can you customize designs with an ODM supplier?

Yes, you can. Many ODM suppliers let you change colors, add logos, or pick special fabrics. You should ask what options they offer before you order.

How long does it take to get custom sweaters?

Production usually takes 15 to 40 days. Shipping can add 5 to 35 days, depending on the method. You should always ask for a timeline before you order.

What certifications should you look for?

You should look for certifications like OEKO-TEX, BSCI, or GOTS. These show the supplier cares about safety, quality, and fair work. Ask for proof before you choose.

What payment methods do ODM sweater suppliers accept?

Most suppliers accept T/T (bank transfer), Letter of Credit, or PayPal. You should ask about payment terms and choose the safest option for your business.

Why is communication important with your supplier?

Good communication helps you avoid mistakes. You get updates, solve problems fast, and build trust. Always choose a supplier who answers your questions clearly and quickly.