If you want to work with a knitwear manufacturer China, you need to prepare ahead of time. Being ready helps you avoid mistakes when dealing with a knitwear manufacturer China. China is a leader in the global knitwear market, and the Asia-Pacific region sells about 25% of all knitwear worldwide. China is well-known for producing large volumes of knitwear, and many brands choose a knitwear manufacturer China because of lower costs, large factory capacities, and access to a wide range of materials.

|

Benefit |

Description |

|---|---|

|

Cost Efficiency |

Prices are usually 20–30% lower for large orders with a knitwear manufacturer China. |

|

Mature Supply Chains |

You can get materials quickly through strong networks with a knitwear manufacturer China. |

|

Large-Scale Capacity |

Factories in China can handle big knitwear orders efficiently. |

|

Access to Diversified Materials |

There are many types of yarns and specialty fibers available from a knitwear manufacturer China. |

Use this guide to avoid common mistakes and ensure you get high-quality knitwear every time you work with a knitwear manufacturer China.

Key Takeaways

-

Get ready before you start working with a knitwear manufacturer in China. This helps you avoid making mistakes.

-

China can save you money. Prices are usually 20-30% less for big orders.

-

Learn the seven main steps in the knitwear manufacturing process. This helps you make sure the quality is good.

-

Pick the right materials and yarns when you design. Make sure they fit your brand’s needs.

-

Make your product requirements clear. Give detailed tech packs to help the manufacturers.

-

Talk clearly with suppliers. This helps you build good relationships and stops confusion.

-

Always check samples for quality and fit before big orders. This helps you avoid expensive mistakes.

-

Plan your budget and timeline well. Give yourself extra time in case production is delayed.

Knitwear Manufacturing Overview

Key Steps in Sourcing and Manufacturing

You need to know how knitwear is made. The process starts with your idea and ends with the finished product. In China, there are seven main steps. Each step helps make sure you get good quality. Here is a simple table that shows the steps:

|

Step Number |

Step Name |

|---|---|

|

1 |

The Design Phase |

|

2 |

Yarn Selection |

|

3 |

Knitting Process |

|

4 |

Dyeing and Treatment |

|

5 |

Shaping and Assembly |

|

6 |

Finishing Touches |

|

7 |

Final Inspection and Packaging |

First, you make your design. Next, you pick the yarn and materials. The factory knits the pieces and then dyes and treats them. After that, they shape and put the clothes together. They add finishing touches. At the end, they check and pack your order. You should watch for new trends in making knitwear. Factories use new fabrics and eco-friendly yarns every year. If you know about these, you can choose better options for your brand.

Why Choose Chinese Knitwear

Many brands choose China for knitwear because it has many benefits. You save money, get lots of fabric choices, and receive orders quickly. The table below shows why China is a good choice:

|

Advantage |

Description |

|---|---|

|

Cost-effectiveness |

You pay less for labor and shipping, but still get good products. |

|

Diverse fabric options |

You can choose from many yarns, even eco-friendly ones. |

|

Logistical efficiencies |

Factories send orders fast and handle supply chains well. |

|

Government support |

The government helps factories, so costs go down and new ideas grow. |

|

Expertise of manufacturers |

You get skilled workers and strong quality checks. |

If you look at China, Bangladesh, Vietnam, or Turkey, China has lower prices, faster shipping, and more fabric choices. This makes China a top place for knitwear.

Common Challenges in Manufacturing

You might have problems when working with Chinese factories. Talking can be hard if you do not set clear rules. Sometimes, suppliers do not tell you about problems right away. You need to ask for updates often and check every detail. Studies show that checking details can stop many mistakes.

Tip: Give clear product details. Check samples before you order a lot. Visit the factory if you can. These steps help you avoid problems and keep quality high.

You should also learn about new yarns and fabric trends. This helps you make smart choices and stay ahead of others.

Preparing Your Knitwear Project

Defining Product Requirements

Start your knitwear project with a clear plan. The design phase guides your work. Decide how you want your knitwear to look and feel. This helps you avoid mistakes later.

Material and Yarn Choices

Pick the right materials during the design phase. Yarn choice changes how your knitwear looks and feels. It also affects cost. You have many yarns to choose from. Here is a table to compare some common yarns and fibers:

|

Raw Material |

Price Characteristics |

Features |

|---|---|---|

|

Cotton |

Stable price, varies by quality |

Soft, breathable, absorbs moisture, may shrink |

|

Polyester |

Cost-effective |

Strong, durable, resists wrinkles, less breathable |

|

Nylon |

More expensive than polyester |

Lightweight, elastic, soft, wears well |

|

Spandex |

More expensive, small impact on cost |

Very stretchy, used for fitted clothing |

|

Acrylic |

Moderately priced |

Warm, soft, light, less durable |

|

Viscose |

Lower-priced, cost-effective |

Soft, shiny, absorbs moisture, weaker than cotton |

|

Modal |

More expensive, high-end |

Soft, glossy, absorbs moisture, used for luxury wear |

|

Wool |

Price varies by type |

Warm, durable, absorbs moisture, needs special care |

|

Silk |

Expensive |

Smooth, shiny, breathable, used for high-end clothes |

|

Bamboo Fiber |

Moderately priced, eco-friendly |

Antibacterial, breathable, absorbs moisture |

Match your yarn choice to your brand’s needs. Some yarns are better for winter clothes. Others work well for summer styles. Pick the right knitting method too. Weft knitting makes soft and stretchy items. Double knitting makes thicker and warmer pieces.

Sizing and Fit

Decide on sizing and fit in the design phase. Use clear size charts for factories. Give measurements for chest, waist, sleeve, and length. Good sizing means fewer returns and happy customers.

Tech Packs and Design Files

A tech pack is a guide for making your knitwear. Prepare detailed design files in the design phase. Include drawings, measurements, yarn choices, and materials. Add color codes, trims, and labels. Factories use tech packs to follow your instructions. This helps you get what you want.

Budget and Timeline Planning

Set your budget early in the design phase. Cost depends on yarn, materials, and knitting methods. Ask factories for quotes. Plan your timeline for each step, from design to delivery. Most projects need extra time for samples and changes. Add time for shipping and customs checks.

Tip: Always add extra days to your timeline for delays. This helps you avoid missing deadlines.

Compliance and Legal Needs

Follow safety and labeling rules when importing knitwear. Check your country’s laws during the design phase. If you sell in the European Union, meet the General Product Safety Directive, REACH chemical rules, and textile labeling laws. For the United States, follow Customs and Border Protection, FTC labeling, and CPSC flammability standards. Do not copy other brands’ designs.

-

General Product Safety Directive (EU)

-

REACH chemical restrictions (EU)

-

Textile labeling rules (EU and US)

-

Flammability standards (US)

-

Environmental rules for textiles (US)

-

Intellectual property protection

Talk to your factory about compliance in the design phase. This helps you avoid legal trouble and keeps your products safe.

Choosing a Knitwear Manufacturer China

Researching Manufacturers

You need to pick the best Chinese knitwear partner for your job. Start by finding good sources. You can search online, go to trade shows, or ask people you know. Each way helps you meet trusted Chinese knitwear manufacturers.

Online Platforms and Trade Shows

Online platforms help you look for Chinese knitwear suppliers. You can see many choices and read what others say. Some popular sites are Alibaba, Made-in-China, and Global Sources. These websites let you sort by place, product, and certificates. Always check the supplier’s page and look for special badges.

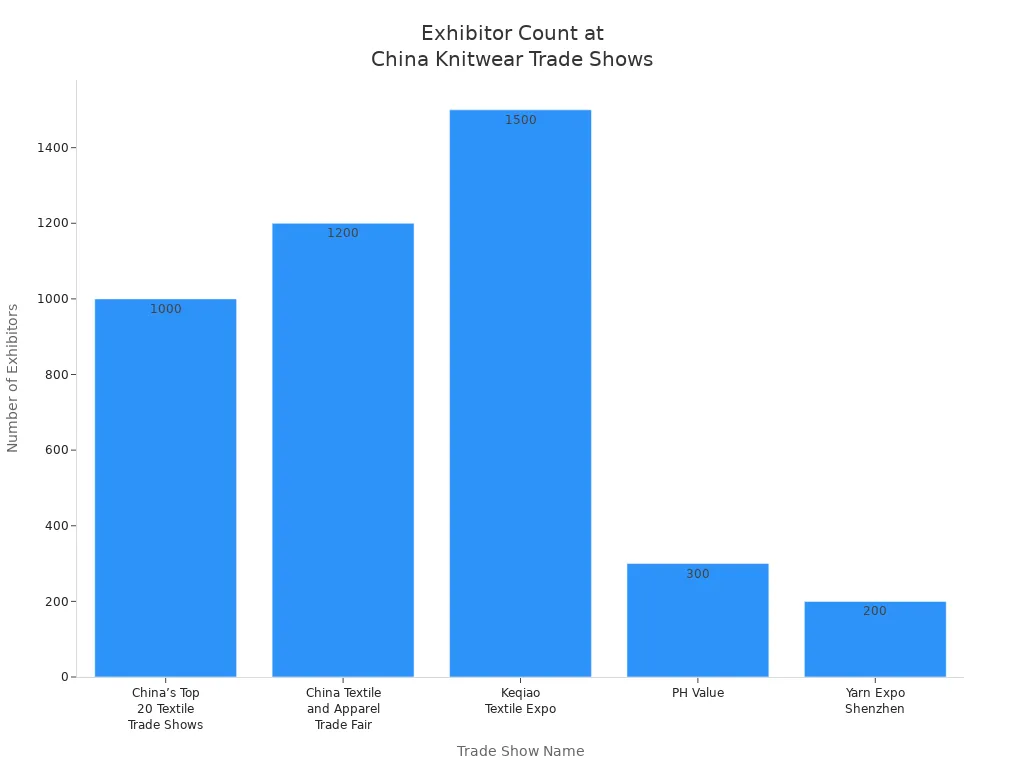

Trade shows let you meet Chinese knitwear manufacturers in person. You can look at samples, ask questions, and compare items. Here is a table of top trade shows for Chinese knitwear:

|

Trade Show Name |

Location |

Exhibitors |

Description |

|---|---|---|---|

|

China’s Top 20 Textile Trade Shows |

Shenzhen |

1,000+ |

Popular among fast fashion brands and nearby garment manufacturers. |

|

China Textile and Apparel Trade Fair |

Beijing |

1,200+ |

Showcases the entire textile supply chain, including sustainable textiles and smart manufacturing. |

|

Keqiao Textile Expo |

Shaoxing |

1,500+ |

Known for competitive prices and variety, attracting 40,000+ visitors from nearby markets. |

|

PH Value |

Shanghai |

300+ |

Premium knitwear trade show featuring knitwear and yarns, attracting designers and buyers. |

|

Yarn Expo Shenzhen |

Shenzhen |

200+ |

Focuses on yarn and fiber exhibitors, catering to the region’s strong knitwear manufacturing base. |

You can learn a lot at these shows. You see new trends and meet many Chinese knitwear suppliers in one place.

Referrals and Networks

Ask people you trust for names of good factories. Other brands, agents, or friends in the business can help you find a knitwear manufacturer China. You can also join online groups about Chinese knitwear. These groups help you find good partners and avoid bad ones.

Evaluating Capabilities

You need to check if a Chinese knitwear supplier fits your needs. Look at their machines, how much they can make, and their quality checks. This step helps you choose a partner who can do the job.

Machinery and Technology

Modern machines help make better Chinese knitwear. Ask if the factory uses computerized knitting machines. These machines make patterns right and lower mistakes. You should also see if the factory works on new ideas. This means they want to make better products.

-

Find factories that teach workers to use new machines.

-

Ask if they can make big orders.

-

Check if they buy yarn from trusted suppliers.

Minimum Order Quantity (MOQ)

Every knitwear manufacturer China has a minimum order quantity. This is the smallest number you must buy. Some Chinese knitwear suppliers take small orders. Others only work with big brands. Always ask about MOQ before you start. This helps you plan your money and not get surprised.

Certifications and Audits

Certifications show a Chinese knitwear supplier meets world standards. You should ask for these papers:

-

GOTS (Global Organic Textile Standard): Checks for organic content and safe processing.

-

OEKO-TEX® Standard 100: Proves the fabric is safe and free from harmful chemicals.

-

Bluesign®: Shows the factory manages chemicals in a safe way.

-

Cradle to Cradle: Focuses on recycling and eco-friendly design.

-

Fair Wear Foundation, SA8000, or WRAP: Protects workers’ rights and ensures fair treatment.

You can also ask for audit reports. These reports show how the factory keeps things safe and good.

Communicating with Suppliers

Good talking is important with Chinese knitwear suppliers. You need to be clear and polite. Here are some tips:

-

Build guanxi, or good relationships, with your supplier. This helps you work together better.

-

Keep your promises and be on time. This shows you are honest.

-

Learn about Chinese customs and business ways.

To help your Chinese knitwear suppliers save face, talk in a careful way. Be firm but not rude. Show respect but do not be too quiet.

Follow these steps for good talking:

-

Use simple words and short notes. Bullet points help a lot.

-

Lead the project yourself. Do not wait for the supplier to lead.

-

Pick one main person to talk to. This stops mix-ups.

-

Use WeChat for messages. Many Chinese knitwear suppliers like this app.

-

Make a quality checklist. Share it with your supplier so they know what you want.

You can stop many problems by using these tips. Good talking helps you get what you want from your Chinese knitwear project.

Comparing Quotes

You should look at quotes from many Chinese knitwear manufacturers. Each factory gives a price based on your design and order size. The price also depends on the materials you pick. Do not just choose the lowest price. Quality and service are important too.

Ask each supplier for a detailed quote. The quote should show the price for each piece and the cost of materials. Some factories add shipping in the price. Others charge more for packaging or special labels. Always ask for a list of all costs. This helps you know what you are paying for.

Many things can change the price:

-

If you order more, the price per piece is lower.

-

Fancy yarns cost more than simple ones.

-

Easy designs are cheaper than hard patterns.

-

Special colors or labels make the price go up.

-

Big factories may cost more but are more steady.

You can use a table to compare the quotes you get:

|

Manufacturer Name |

Price Per Piece |

Minimum Order Quantity |

Reorder Rate |

Special Notes |

|---|---|---|---|---|

|

Guangzhou Junma Apparel Co., Ltd. |

High |

Large |

50% |

Premium pricing, high volume |

|

Dongguan Cainan Clothing Co., Ltd. |

Medium |

Medium |

Good balance of price/quality |

|

|

Xiamen Cis Industrial Co., Ltd. |

Medium |

Medium |

Lower |

Limited customization |

|

Dongguan Fnjia Knitwear Co., Ltd. |

Medium |

Medium |

Lower |

Less competitive pricing |

|

Dongguan Kangduo Clothing Co., Ltd. |

Low |

Small |

Not listed |

May struggle with big orders |

Tip: Do not pick a factory just because it is cheap. Factories with high reorder rates often give better quality. Make sure the supplier can handle your order and finish on time.

You can ask for samples from each factory. Samples help you check the quality. You can see if the quote matches what you want. If you need something special, ask for a custom quote. Check if the supplier has made your type of knitwear before.

Watch out for hidden costs when you compare quotes. Some factories charge more for fast orders or special packaging. Read the quote carefully. Ask questions if you do not understand something.

You can make a checklist to help you compare:

-

Price per piece

-

Sample quality

-

Minimum order size

-

Delivery time

-

Extra costs

-

Reorder rate

Pick a supplier who gives you good value, not just the lowest price. This helps you get good knitwear and build a strong business relationship.

Sampling Process in Knitwear Manufacturing

Sampling is an important step in making knitwear. You use samples to check quality, fit, and design before making lots of pieces. This helps you avoid expensive mistakes and makes sure your products are good.

Types of Samples

You will see different samples when making knitwear. Each sample helps you make choices.

Proto, Fit, and Pre-Production

-

Proto Sample: This is the first sample you get. It shows the basic design and how it is made. You use it to see if the manufacturer understands your idea.

-

Fit Sample: You get this sample next. It helps you check the size and fit. You can put it on a model or mannequin to see if it is right.

-

Pre-Production Sample: This is the last sample you get. It uses the final materials and ways of making. You use it to check color, stitching, and finishing before making many pieces.

Lead Times and Costs

You need to plan for how long samples take and how much they cost. Most Chinese manufacturers follow a set schedule. Here is a table to show the process:

|

Process |

Timeframe |

|---|---|

|

Production |

|

|

Shipping (Economy) |

7–14 days |

|

Shipping (Express) |

3–5 days |

|

Total Timeline |

2–4 weeks |

You should expect to pay for each sample. The price depends on how hard your design is and what materials you pick. Express shipping costs more but is faster.

Reviewing and Revising Samples

You must look at each sample closely. This helps you find problems early.

Feedback and Adjustments

Give clear feedback to your manufacturer. Use pictures, notes, and measurements to show what you want to change. Ask for fixes if you see mistakes or if the sample does not match your tech pack. Good talking helps you get what you want.

Tip: Always check the sample against your original design and tech pack. This helps you spot differences fast.

Common Issues and Solutions

You may find problems when you look at samples. Here are some common things to watch for:

-

Problems with hemming

-

Loose threads

-

Small holes

-

Yarn slubs you did not see

-

Linking problems

-

Color shade changes

-

Too much shrinking

-

Colors bleeding

-

Fabric getting twisted

-

Handfeel problems

-

Wrong length or width

-

Sleeves not the same length

-

Missed stains

-

Holes from yarn breaking or missed loops

-

Label mistakes in main or care labels

-

Pressing marks

-

Wrong labels or barcodes

-

Broken packaging

-

Mixed sizes in boxes

-

Not matching buyer specs

-

Missed workmanship mistakes

-

Not matching approved samples

You should fix these problems before making lots of pieces. Ask your manufacturer to fix them and send a new sample.

Final Sample Approval

You need to say yes to the final sample before making many pieces. Follow these steps to make sure everything is right:

-

Give your finished tech pack, close-up stitch pictures, and a real sample if you have one.

-

Confirm the yarn type and give a yarn sample if you can.

-

After the manufacturer gets everything, work with them and check the detailed quote.

Once you say yes to the final sample, you can start making lots of knitwear. This helps you avoid surprises and makes sure your knitwear is good.

Production in Chinese Knitwear Factories

Material Sourcing and Prep

You start your knitwear production in China by choosing and preparing materials. Factories in China follow a clear process to make sure your knitwear meets your needs. Here is how the main stages look:

|

Stage |

Description |

|---|---|

|

Fiber Selection & Processing |

Raw materials like cotton, wool, or polyester are cleaned and prepared. |

|

Spinning & Yarn Formation |

Fibers are twisted into threads or yarn. |

|

Weaving or Knitting |

Yarn is interlaced (woven) or looped (knitted) to form fabric. |

Yarn Procurement and Testing

You need to pick the right yarn for your project. In China, factories buy yarn from trusted suppliers. They test the yarn for strength, color, and feel. This step helps you avoid problems later. You should ask for yarn samples before production starts. Testing makes sure the yarn does not break or shrink too much.

Dyeing and Color Matching

Color is important for your brand. In China, factories use special dyeing machines to get the right shade. They test small batches first. You should always approve a color swatch before the factory dyes all the yarn. This step helps you avoid surprises. If you want bright or eco-friendly colors, tell your supplier early.

Knitting and Assembly

After the yarn is ready, factories in China start knitting and assembling your pieces. The knitting method and gauge change how your knitwear looks and feels.

Knitting Techniques and Gauge

Factories in China use many knitting techniques. Each one gives a different look and texture. The gauge means how tight or loose the stitches are. Here is a table to show common techniques and their best gauges:

|

Knitting Technique |

Best Gauges |

|---|---|

|

Cable Knitting |

3G–7G |

|

Jacquard |

3G–14G |

|

Intarsia |

N/A |

|

Pointelle |

12G–16G |

|

Waffle |

5G–12G |

|

Rib |

N/A |

You can ask your factory in China to show samples of each technique. This helps you pick the best one for your design.

Linking and Sewing

After knitting, workers in China link and sew the pieces together. Linking joins the seams for a smooth finish. Sewing adds strength to the garment. You should check the seams for neatness and comfort. Good linking and sewing make your knitwear last longer.

Finishing Steps

Factories in China finish your knitwear with care. These steps give your products a clean look and feel.

Washing and Blocking

Washing removes oils and dirt from the yarn. Blocking shapes the garment and sets the size. In China, factories use special machines for these steps. You should ask for a sample after washing and blocking to check the final look.

Labeling and Tagging

The last step is adding labels and tags. In China, factories sew in care labels, size tags, and your brand label. You can also ask for hangtags or special packaging. Make sure the labels meet your country’s rules.

Tip: Always check a finished sample before full production. This helps you catch mistakes early and keeps your brand strong.

Managing Timelines

You must keep your project on track with Chinese knitwear factories. Timelines are important because delays can hurt your sales. Delays can also damage your reputation. Factories in China use strict schedules for every order. They plan each step, like buying yarn and shipping products. You should learn how factories manage time to avoid problems.

Factories organize orders by size, season, and design difficulty. Big orders need more time to finish. Busy times, like winter or holidays, slow down production. If you want your knitwear fast, order early. Factories check if they have enough materials before starting. If yarn or trims are missing, your order might be late.

Many factories use digital tools to watch progress. TrackIT is a popular system. It gives updates and reports in real time. You can see each stage, from yarn arrival to packing. TrackIT lets you talk with vendors and fix problems quickly. The table below shows how TrackIT helps with timelines:

|

Solution |

Features |

Benefits |

|---|---|---|

|

TrackIT |

Real-time updates, detailed production reports, vendor collaboration tools |

Monitors every stage of production from raw material procurement to final delivery. |

|

|

User-friendly design, adapts to existing workflow |

Ensures minimal disruption during implementation, allowing operations to continue smoothly. |

Ask your factory if they use a tracking system. If they do, you can follow your order and spot delays early. If not, check in often. Use short messages and ask for weekly updates. This helps you stay informed and make quick choices.

Factories set priorities based on how busy they are. If your order is urgent, tell the factory right away. Some factories can rush orders for extra money. Plan for more time if your design is hard or uses special yarns.

Tip: Always add extra days to your timeline. This helps you avoid stress if something goes wrong.

Here are steps to help you manage your timeline:

-

Set clear deadlines for design, sampling, production, and shipping.

-

Make sure materials are ready before you start.

-

Use tracking tools or ask for updates often.

-

Plan for busy seasons and holidays.

-

Share changes quickly.

If you manage your timeline well, you get your knitwear on time. Your customers will be happy. Good planning helps you avoid delays and build trust with your factory.

Quality Control in Knitwear Manufacturing

You want your knitted clothing to be very good. You need to check quality at every step. Factories in China use clear rules to check each item. This helps keep the quality high.

Setting Quality Standards

You must set your rules before making anything. These rules help you get what you want. Factories in China follow their own and national rules. Here is a table with some common rules:

|

Quality Standard |

Description |

|---|---|

|

FZ/T 73077-2024 |

New rule for quick-dry knitted clothes, starts January 1, 2025. |

|

Safety Requirements |

Follows GB 18401 and GB 31701 for kids’ clothes. |

|

Internal Quality Requirements |

Tests for fiber, formaldehyde, pH, smell, color, strength, pilling, and how well it absorbs. |

Ask your supplier to use these rules for every piece. You can also add your own rules for color, fit, or feel.

Acceptable Quality Levels (AQL)

AQL means how many mistakes you will allow. You pick this number before making your order. Most brands use AQL 2.5 or 4.0 for knitwear. Lower numbers mean stricter checks. Tell your factory your AQL so they know how to check.

Inspection Checklists

You need a list to check every order. This list helps you look at each part of your knitwear. Your list should have:

-

Yarn type and color

-

Stitch count and pattern

-

Size and fit

-

Label and tag spots

-

Seam strength

-

Color staying strong

-

Smell and pH

-

Pilling and bursting strength

Share this list with your supplier. This helps them check before sending your order.

Inspections and Testing

You must check your knitwear during and after making it. Checks help you find problems early. Factories in China use two main types of checks. Here is a table that shows what they look for:

|

Type of Inspection |

Focus Areas |

|---|---|

|

Garment Inspections |

Checks patterns, materials, stitches, fabric weight, and size. |

|

Textile Inspections |

Looks at fabric quality, if it matches your needs, and how it is made. |

You can ask for photos or reports from these checks. You can also visit the factory to see the knitwear yourself.

Third-Party and Factory Checks

You can hire outside inspectors for extra safety. These people check your knitwear before it leaves the factory. They use your list and AQL. Factory workers also check during making. Both checks help you get good quality.

Tip: Always ask for reports from checks. These reports show if your knitwear meets your rules.

Handling Defects

You may find problems in your knitwear. You need a plan to fix them. Common problems are loose threads, wrong sizes, or color issues. Tell your supplier about problems right away. Ask them to fix or swap the bad items.

You can use these steps to fix problems:

-

Check all knitwear when it arrives.

-

Write down any problems you see.

-

Share your list with the supplier.

-

Ask for fixes or new items.

-

Keep notes of all problems and fixes.

If you do these steps, your knitwear will stay good. Good checks help you build trust with buyers and suppliers.

Packaging and Shipping Knitwear

When you finish making your clothing in China, you need to think about packaging and shipping. Good packaging protects your clothing and helps your brand stand out. Shipping methods affect how fast your clothing reaches you and how much you pay. You also need to understand customs and import duties to avoid problems.

Packaging Options

You have many choices for packaging your clothing. Factories in China offer different options to match your needs. You can pick packaging that fits your brand and keeps your clothing safe.

-

Many brands now use eco-friendly packaging for clothing. This helps reduce waste and shows you care about the environment.

-

You can choose packaging made from recycled paper, biodegradable bags, or compostable materials for your clothing.

-

Some factories offer custom packaging for clothing. You can add your logo, colors, or special designs to make your clothing stand out.

-

Eco-friendly packaging protects your clothing and gives customers a good unboxing experience.

-

Custom packaging lets you match your clothing to your brand style. You can pick the size, shape, and look you want.

-

Regular plastic packaging for clothing creates a lot of waste. Many countries now ask for sustainable packaging for clothing.

-

You can ask your supplier for packaging that fits your clothing and meets new rules.

Custom and Eco-Friendly Choices

You can work with your factory to design custom packaging for your clothing. Custom boxes, bags, and tags help your clothing look special. Eco-friendly choices for clothing packaging include recycled cardboard, plant-based plastics, and reusable bags. These options protect your clothing and help the planet. You can also add custom labels or stickers to your clothing packaging. This makes your clothing easy to find and gives your customers a good feeling when they open their clothing.

Shipping Methods

You need to pick the best way to ship your clothing from China. Each method has different costs and times. You should choose the one that fits your budget and schedule.

|

Transit Time |

Cost |

|

|---|---|---|

|

Sea Freight |

25–40 days |

Lowest per unit cost |

|

Air Freight |

3–7 days |

Higher than sea freight |

|

Express Courier Shipping |

3–5 business days |

Higher than air and sea freight |

|

Door-to-Door Delivery |

30–45 days (sea), 7–12 days (air) |

All-inclusive, varies by service |

Sea freight works well for large clothing orders. You pay less per piece, but your clothing takes longer to arrive. Air freight is faster for clothing, but you pay more. Express courier shipping gets your clothing to you quickly, but costs the most. Door-to-door delivery for clothing includes customs and local transport. You can ask your supplier which shipping method works best for your clothing.

Air and Sea Freight

You can use air freight for urgent clothing orders. Your clothing arrives in less than a week. Sea freight is better for big clothing shipments. You save money, but your clothing takes longer. You should plan your clothing orders based on how fast you need them.

Incoterms and Documentation

Incoterms tell you who pays for shipping, insurance, and customs for your clothing. Common Incoterms for clothing include FOB (Free On Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). You should ask your supplier which Incoterm they use for your clothing. You also need documents like invoices, packing lists, and bills of lading for your clothing. These papers help you clear customs and get your clothing on time.

Customs and Import Duties

When you import clothing from China, you must pay customs duties and taxes. Each country has its own rules for clothing. You should check the duty rates for clothing before you order. Some clothing types have higher taxes. You need to fill out forms and pay fees to get your clothing through customs. Your shipping agent or supplier can help you with clothing import paperwork. If you follow the rules, your clothing arrives without delays.

Tip: Always check the latest rules for clothing imports. This helps you avoid extra costs and keeps your clothing business running smoothly.

After-Sales and Ongoing Support

Reorders and Repeat Production

You need a reliable process for reorders and repeat production. When you find a knitwear manufacturer in China that delivers high-quality knitwear, you want to keep working with them. You should keep your sourcing records organized. This helps you repeat orders without mistakes. You can use a simple table to track your sourcing details:

|

Order Number |

Style Name |

Yarn Type |

Quantity |

Delivery Date |

|---|---|---|---|---|

|

001 |

Crewneck |

Cotton |

500 |

2024-09-10 |

|

002 |

Cardigan |

Wool |

300 |

2024-10-05 |

You should share feedback from your last order with your supplier. This helps them improve your next batch. If you want to change colors or sizes, update your sourcing documents. You can ask for a sample before starting repeat production. This step helps you keep your high-quality knitwear standards.

Tip: Always confirm your sourcing requirements before placing a reorder. This helps you avoid confusion and keeps your production smooth.

Returns and Defects

Sometimes you get products that do not meet your standards. You need a clear plan for returns and defects. Good sourcing practices help you spot problems early. You should check every shipment when it arrives. If you find defects, take photos and write down the issues. Share this information with your supplier right away.

You can use a checklist to review your high-quality knitwear:

-

Check for loose threads

-

Look for color differences

-

Measure sizes

-

Inspect labels and tags

If you need to return items, ask your supplier about their sourcing return policy. Some factories offer free replacements for defective products. Others may give you a discount on your next order. You should keep records of all returns and defects. This helps you improve your sourcing process in the future.

Building Long-Term Partnerships

You build strong partnerships by communicating well after delivery. When you work with a knitwear manufacturer in China, you should share your sourcing goals and future plans. Good relationships help you get better prices and faster service. You can send thank-you notes or share positive feedback when you receive high-quality knitwear.

Factories value customers who order regularly. You can ask your supplier about new sourcing options or special yarns. This helps you stay ahead of trends and offer unique products. You should visit the factory if possible. Meeting in person builds trust and helps you solve sourcing problems quickly.

Note: Long-term partnerships make sourcing easier and help you get consistent high-quality knitwear. You save time and money when you work with a trusted supplier.

You can use these steps to build strong sourcing relationships:

-

Communicate clearly and often

-

Share feedback and suggestions

-

Visit the factory when you can

-

Ask about new sourcing trends

-

Thank your supplier for good work

If you follow these steps, you will enjoy smooth sourcing and get high-quality knitwear every time.

Continuous Improvement

You should always look for ways to improve your knitwear sourcing process. Continuous improvement helps you get better products and build a stronger business. When you work with a knitwear manufacturer in China, you can use simple steps to make your process better each time.

Start by collecting feedback from your customers. Ask them what they like and what they do not like about your knitwear. You can use surveys, reviews, or direct messages. Write down common problems or requests. Share this feedback with your supplier. This helps your manufacturer understand what you need.

Review each order after you receive it. Check the quality, fit, and packaging. Compare the results to your last order. Look for changes or mistakes. If you see a problem, talk to your supplier right away. Good communication helps you fix issues before your next order.

You can use a table to track your improvements:

|

Order Date |

Issue Found |

Solution Used |

Result |

|---|---|---|---|

|

2024-03-10 |

Loose threads |

Changed stitching |

No loose ends |

|

2024-05-15 |

Wrong label |

Updated tech pack |

Correct labels |

|

2024-07-01 |

Color mismatch |

Sent color swatch |

Colors match |

Set clear goals for each new order. You might want fewer defects, faster delivery, or better packaging. Share these goals with your supplier. Ask them how they plan to meet your goals. You can also ask for new ideas or better materials.

Tip: Visit your factory if you can. Seeing the process helps you find ways to improve. You can talk to workers and learn about new machines or methods.

Keep learning about new trends in knitwear. Factories in China often use new yarns, eco-friendly dyes, or smart machines. Ask your supplier about new options. Try small changes in your next order to see what works best.

You should also review your own process. Check your tech packs, order forms, and timelines. Make sure your instructions are clear and easy to follow. Update your documents when you find mistakes.

Continuous improvement helps you grow your business. You get better products, save money, and keep your customers happy. Work with your supplier to make small changes each time. Over time, these changes lead to big results.

You can do well with Chinese knitwear manufacturers if you follow these steps. First, get your project ready and make sure your requirements are clear. Next, talk openly with suppliers so everyone understands. Always check the quality at each stage to catch problems early. This guide helps you avoid mistakes and get good results every time.

Tip: Look at trade shows, online websites, and industry groups for more information. You can keep learning new things and make your sourcing process better.

FAQ

What are knitted fabrics and why do brands use them?

You see knitted fabrics in fashion because they stretch and feel soft. Many brands choose them for comfort and style. The knitting garment industry uses these fabrics to make sweaters, scarves, and hats.

How do I choose the right color for custom knitwear?

You pick a color that matches your brand or season. Factories offer many shades. Always ask for a sample before production. This helps you see the color in real life and avoid surprises.

What is the final inspection and packaging process?

You check your custom knitwear for mistakes during final inspection and packaging. Workers look for loose threads, wrong color, and size issues. Good packaging keeps your knitted fabrics safe during shipping.

Can I order custom knitwear in small quantities?

You can order custom knitwear in small batches. Some factories accept low minimums. This helps you test new designs or colors before making large orders in the knitting garment industry.

How do factories ensure high-quality fabrics and craftsmanship?

You get high-quality fabrics when factories use strict checks. Skilled workers focus on craftsmanship. They test color, strength, and softness. Final inspection and packaging help keep your custom knitwear looking great.

What should I do if the color is wrong in my order?

You should contact your supplier right away. Show them photos of the wrong color. Ask for a fix or replacement. Final inspection and packaging help catch color mistakes before shipping.

How does custom knitwear help my brand stand out?

You design custom knitwear with special colors, patterns, or labels. This makes your brand unique. Knitted fabrics in fashion let you offer new styles. Final inspection and packaging keep your products looking professional.

Why is color important in knitted fabrics in fashion?

You notice color first in knitted fabrics in fashion. It sets the mood and style. The knitting garment industry uses color to match trends. Custom knitwear lets you pick colors that fit your brand.

Tip: Always ask for a color swatch before production. This helps you avoid mistakes and get the shade you want.