You will see these top companies lead the computerized knitting factory area in 2025: Shima Seiki, Stoll, Mayer & Cie., Santoni, and East (Quanzhou) Intelligent Technology.

Each company is special for new ideas, many products, big market power, and smart ways to help the environment. In 2025, the world market for knitting machines will be $13.61 billion. Industrial knitting equipment is changing fast. Automation, AI, and IoT help people want better and custom textile solutions.

Key Takeaways

-

Leading companies in computerized knitting are Shima Seiki, Stoll, Mayer & Cie., Santoni, and East (Quanzhou). Each company has special ideas and uses ways that help the environment. The market for knitting machines may reach $13.61 billion by 2025. This is because people want custom and high-quality textiles. Automation, AI, and IoT are changing knitting factories. These tools help make things faster and improve quality checks. Using eco-friendly materials and energy-saving designs is very important. Many companies now use these to make less waste. When picking knitting machines, think about the technology, how you can change the machine, how well it works, and the help you get after buying. Buying advanced knitting technology can save a lot of money and make work faster. Seamless knitting technology, like the kind from Santoni, helps cut down on fabric waste and makes clothes more comfortable. Make sure your factory’s goals match with helping the environment. Pick machines that use green methods and recycled materials.

Industry Overview and Market Trends

Growth of Computerized Knitting Factories

Computerized knitting factory equipment is changing how textiles are made. Many factories use advanced knitting machines to work faster and smarter. In June 2025, Tajima showed the T-Series X-2000. It is a high-speed computerized flat knitting machine. This machine has AI-assisted maintenance and IoT remote monitoring. Smart technology like AI-powered systems and IoT machines is now common in factories. The market shows more people want knitted clothes. Automation and new methods help factories keep up with these needs.

-

Tajima’s T-Series X-2000 uses AI and IoT in knitting.

-

Smart knitting machines make factories work faster and better.

-

More people want custom and high-quality knitted things.

Demand for Industrial Knitting Equipment

Industrial knitting equipment is wanted by many factories, especially in Asia-Pacific. China and India are leading this growth. Cities are growing and more people use digital tools, so factories grow quickly. Southeast Asian countries like Indonesia and Vietnam are also important. Latin America and the Middle East & Africa see more factories buying knitting machines. Good economies and new rules help this growth.

The need for industrial knitting equipment comes from many things:

-

Customers want more choices and faster service.

-

Making textiles in a green way is very important now.

-

Automation and precision help factories make more with less waste.

-

Smart textile technology means less manual work.

-

Energy-saving designs help save power and money.

-

Fashion and technical textiles need quick and good production.

-

More people buy knitted goods, so the market grows.

-

New designs and features make machines more flexible.

-

Factories want green and custom production.

Trends in Sustainable Textile Production

Sustainable textile production is very important for many companies. More factories use eco-friendly materials like recycled polyester, organic cotton, hemp, and biodegradable yarns. New dyeing methods, like digital printing and plant-based dyes, use less water and make less waste. Zero-waste knitting helps factories make clothes with almost no leftover fabric.

Factories use 3D knitting technology to make seamless and custom products. This helps the environment. Waterless dyeing and supercritical CO2 dyeing save water and lower pollution. Many mills use recycled yarns from plastic bottles and natural fibers that break down easily.

Here is how top manufacturers support sustainable textile production:

|

Manufacturer |

Sustainable Practice |

|---|---|

|

Shima Seiki |

Focus on sustainability and digital design |

|

Stoll |

Knitelligence® platform supports circular textile economies |

|

Mayer & Cie. |

Energy-efficient designs and faster service response |

|

Santoni |

Seamless technology reduces fabric waste by 25% |

|

Pailung |

Energy-efficient drives save 15% power |

|

Orizio |

Automated tension control reduces yarn waste by 15% |

Computerized seamless knitting machines and circular knitting machines help factories use less energy and make less waste. Sustainable textile production is not just a trend. It is something companies and customers now expect.

Top Knitting Machine Manufacturers in 2025

Shima Seiki: Innovation in Computerized Knitting

Shima Seiki is a leader in computerized knitting. The company uses smart technology and new ideas. Their WHOLEGARMENT knitting machines, like the SWG-XR, have four needle beds. This design helps make all-needle fabrics. It boosts how much you can make by over 25%. You can use many yarns, so you get more fabric choices. These machines help make clothes with almost no waste. This supports making textiles in a green way.

Shima Seiki gives you strong design tools. The SDS-ONE APEX4 software lets you make virtual samples. You can see your designs before making them. This saves time and money. The Apexfiz tool helps you make 3D fabric samples on your computer. You do not need to waste yarn or fabric for testing. This helps you meet the need for custom and high-quality products.

Here is a quick look at Shima Seiki’s main innovations:

|

Innovation |

Description |

|---|---|

|

WHOLEGARMENT Knitting Machines |

SWG-XR has 4 needle beds for all-needle knitting. It makes more fabric and uses many yarns for new types. |

|

Design Software |

SDS-ONE APEX4 helps design clothes with virtual samples. It saves time and money. |

|

Apexfiz Software |

This tool lets you make 3D fabric samples on your computer. You do not need to use real yarn or fabric. |

Tip: Shima Seiki’s focus on digital design and waste-free production makes it a good choice if you want to lead in smart and green textile manufacturing.

Stoll: Advanced Industrial Knitting Equipment

Stoll is a top knitting machine maker. They build custom machines for many fabric types. You can pick machines that fit your needs. This works for fashion, sportswear, or technical textiles. Stoll’s design helps you get the best results.

Stoll’s advanced knitting equipment uses the Knitelligence® platform. This system helps you manage machines and data in one place. You can track production and spot problems. You can plan better. Stoll’s machines work for small and large factories. You get high flexibility and strong performance.

Stoll invests in research and development. This helps you keep up with new fabrics and styles. Stoll also supports circular textile economies. This means you can recycle and reuse materials more easily.

Mayer & Cie.: Efficiency and Quality

Mayer & Cie. is known for reliable knitting equipment. Their machines run smoothly and last a long time. Mayer & Cie. uses a new IoT-ready control system. This system lets you check and manage machines from anywhere. You get better control and faster service.

The Relanit 3.2 HS model is a good example of energy-saving design. This machine uses up to 30% less energy than older models. You save money and help the environment. Mayer & Cie. also improves fabric quality. Their new sinker design reduces faults. This is helpful when you use sustainable cotton.

Here is a table showing Mayer & Cie.’s main benchmarks:

|

Benchmark |

Description |

|---|---|

|

Machine Control System |

New IoT-ready system lets you control machines from anywhere. |

|

Energy Efficiency |

Relanit 3.2 HS uses up to 30% less energy than older machines. |

|

Fabric Quality |

New sinker design lowers fabric faults, especially with sustainable cotton. |

|

Downtime Reduction |

Better design means less downtime and more productivity. |

Mayer & Cie. helps you meet the need for fashion and technical textiles. Their circular knitting machines and computerized flat knitting machines give you many choices for your factory.

Key Criteria for Choosing the Best Knitting Machines

When you look for the best knitting machines, think about these points:

-

Technological innovation and automation

-

Product range and customization

-

Quality and reliability

-

Pricing and cost of ownership

-

Customer support and service

-

Global presence and supply chain

-

Compliance and certifications

-

Future upgrades and R&D

Here is a chart showing how much each factor matters:

You can use this chart to help you pick the right manufacturer for your needs.

Santoni: Leading Computerized Seamless Knitting Machine Companies

Santoni is one of the top companies for computerized seamless knitting machines. The company started in 1919 and made machines for socks in Italy. In 1988, Santoni joined the Lonati Group and became a leader in electronic knitting machines for seamless clothes. Their machines are used in many factories all over the world.

Santoni works hard to build a new way for factories to work together. They care about new ideas, helping the planet, and using digital tools. Their advanced knitting equipment lets you make seamless clothes with less waste. This is important because more people want factories to be green.

-

Santoni thinks the market for circular knitting machines will get bigger. Experts say it will grow by 5.7% every year from 2023 to 2030.

-

The company is a leader in computerized seamless knitting machine technology. You can use their machines to make sportswear, underwear, and fashion items that are comfortable and high quality.

-

Santoni’s machines help save energy and cut down on fabric waste. This means you can reach your factory goals and help the environment.

Franco Sciacca from the Lonati Group says, “Santoni is now known as the world leader in Seamless, and we want to explore different technologies so that we can widen the reach of Seamless.”

Santoni has many types of industrial knitting equipment you can pick from. Their machines work with smart factory systems. You can connect them to computers for better control and planning. If you want to be a leader in computerized knitting factories, Santoni gives you the right tools.

East (Quanzhou) Intelligent Technology: Intelligent Knitting Solutions

East (Quanzhou) Intelligent Technology gives smart solutions to textile factories. Their automatic circular knitting machines help you make more products faster. You can finish bigger orders and keep up with more people wanting knitted things. These machines also make your products better and your work quicker.

-

East (Quanzhou) has industrial knitting equipment that helps factories be more green.

-

Their machines use less energy. This saves power and money.

-

The company’s technology helps you make less waste and makes your factory better for the environment.

You can trust East (Quanzhou) for advanced knitting equipment. Their machines work well with computerized flat knitting machines and other systems. You can build a smart factory that fits what people need today. If you want great knitting machines for your business, East (Quanzhou) is a strong choice.

Both Santoni and East (Quanzhou) are important companies for knitting machines. They help you make high-quality, green, and fast textile products.

Company Profiles and Strengths

Shima Seiki: Technology and Product Range

Shima Seiki is a leader in computerized knitting technology. The company has many types of industrial knitting equipment. Their advanced knitting machines help you make more products. You can use their design systems to create and manage designs fast. Online services help you at every step of your supply chain. This makes your work easier and more efficient.

Here is a table that shows what Shima Seiki offers:

|

Product Type |

Description |

Application Area |

|---|---|---|

|

Advanced Knitting Machines |

High-quality machines that help you make more textiles. |

Textile and Fashion Industries |

|

Design Systems |

Tools that help you design and manage your work quickly. |

Design and Development |

|

Online Services |

Web services that help with every part of the supply chain. |

Manufacturing and Sustainability |

You can use Wholegarment flat knitting machine technology to make seamless items. This helps you cut down on waste and meet the need for green textile production. The SDS-ONE APEX series lets you make virtual samples that look real. You can see your ideas before using real yarn. This saves you time and money. Shima Seiki helps you work smarter and faster, so you can keep up with new trends.

Stoll: High-Volume Production Capabilities

Stoll is known for helping factories make lots of products. You can pick manual, semi-automated, or fully automated knitting equipment. Manual and semi-automated models are good for custom or small orders. Fully automated systems feed yarn, change patterns, and find errors by themselves. These are great for making many items at once.

The table below shows Stoll’s main features:

|

Feature |

Description |

|---|---|

|

Manual/Semi-Automated Models |

Need more help from workers but are good for small or custom jobs. |

|

Fully Automated Systems |

Feed yarn, change patterns, and find mistakes automatically, perfect for big orders. |

|

Industry 4.0 Integration |

Connects to data and lets you watch production from anywhere, making work easier and better. |

|

High-Speed Production |

Makes clothes much faster than old machines. |

|

Energy Efficiency |

Uses less energy, so you save money and help the planet. |

|

Scalability |

Lets your business grow easily because the machines are reliable and work well together. |

You can connect Stoll’s machines to smart factory systems. This means you can check your work from anywhere. Fast production helps you deliver orders quickly. Energy-saving designs lower your costs and help the earth. Stoll’s machines let your business grow when the market changes.

Mayer & Cie.: Reliability and Market Impact

Mayer & Cie. is trusted for reliable knitting equipment. Many factories use their machines for fashion and technical textiles. At the ITMA 2007 trade fair, almost 7,000 people visited Mayer & Cie. This shows they are important in the market. People from Asia and South America were very interested. This proves Mayer & Cie. has a big global impact.

You can use their special MCS (Mayer Cleaning System). It helps clean and cool the knitting heads. Your needles and sinkers last longer. You get better fabric and need to clean less often. Mayer & Cie. has circular knitting machines and computerized flat knitting machines. These help you make both regular and custom products. You can also use their machines for seamless knitting.

Tip: If you want strong and trusted machines, Mayer & Cie. gives you what you need to do well in a tough market.

Santoni: Seamless Knitting Innovations

Santoni is a leader in seamless knitting. Their computerized seamless knitting machine helps you make high-quality clothes. You can make products with fewer steps. You do not need to sew or finish after knitting. This saves time and lowers labor costs. You can make more items with less work.

Seamless knitting technology has many good points. Here is a table that shows these benefits:

|

Benefit |

Description |

|---|---|

|

No sewing or finishing needed, so you save money and work faster. |

|

|

Enhanced Design Flexibility |

You can make lingerie with many layers and styles. |

|

Superior Comfort and Fit |

Seamless clothes feel smooth and do not have rough seams. |

|

Sustainable Production |

You use less fabric and help the planet by making less waste. |

Santoni’s industrial knitting equipment lets you make activewear, lingerie, and fashion items. Seamless clothes feel soft and comfy. You do not feel seams on your skin. This is great for sports and daily wear.

Santoni’s knitting machines help you make textiles in a green way. You use only the yarn you need. This means less fabric waste and helps the earth. You can make new designs without extra sewing. This gives you more ways to make special products.

Here are some main benefits of Santoni’s seamless knitting:

-

Less fabric waste and more green production

-

Better comfort and fit

-

Faster making and saving money

-

More ways to design clothes

You can change your products quickly when the market changes. Santoni’s circular knitting machines let you make many styles and sizes. You can make custom and green products. Santoni helps you stay ahead in computerized knitting factories.

East (Quanzhou): Smart Factory Integration

East (Quanzhou) Intelligent Technology helps you build a smart textile factory. Their industrial knitting equipment uses digital controls and sensors. You can make more items with less manual work. These machines help you make stitches more accurately and improve quality.

East (Quanzhou) uses IoT in their computerized knitting factory solutions. You get data right away. You can watch how machines work and know when they might stop. This helps you plan better and avoid problems. You can make your work faster and easier.

You can use East (Quanzhou)’s computerized seamless knitting machine to make whole-garment knitwear in one step. This helps you make textiles in a green way. You make less waste and can make special products for your customers. Their circular knitting machines also help you make flexible and eco-friendly products.

Here is what East (Quanzhou) gives you:

-

Digital controls and sensors for better work

-

IoT for watching machines in real time

-

Whole-garment making for less waste

-

Help for green manufacturing

East (Quanzhou) gives you tools for a smart and fast factory. You can make high-quality, custom, and green textile products. Their industrial knitting equipment helps you do well in a changing market.

Comparative Analysis of Top Manufacturers

Performance and Reliability

When you look at top knitting machines, check how well they work. You want machines that run smoothly and do not break often. Factories need equipment that can keep up with work every day. Good machines help make high-quality textiles all the time.

Here is a table with important things to check for performance and reliability:

|

Metric |

Description |

|---|---|

|

Efficiency |

Shows how much you get for what you use. |

|

Speed |

Tells how fast the machine can knit items. |

|

Stitch Quality |

Shows if the stitches are neat and strong. |

|

Ease of Use |

Tells if workers can use the machine easily. |

|

Durability |

Shows how well the machine lasts over time. |

|

Maintenance Costs |

Tells how much you spend to keep it working. |

|

User Satisfaction |

Shows how happy people are with the machine. |

|

Versatility |

Tells if the machine can make many products. |

|

Compact Design |

Shows if the machine fits well in your space. |

Think about speed, stitch quality, and if the machine is easy to use. Some machines, like computerized seamless knitting machines, can make many types of products. They also fit well in small spaces. How long a machine lasts depends on how it is built. If you want a machine for many years, pick one that is strong and does not need many repairs.

Customization and Flexibility

Factories need machines that can change when the market changes. You want equipment that lets you make many styles and sizes. Customization helps you fill special orders and follow new fashion trends.

-

Orizio has large-diameter circular knitting machines. You can work with their team to design machines for special fabrics.

-

WHOLEGARMENT® technology uses the SDS®-ONE APEX series design system. You can make virtual samples and test ideas before making real products. This makes your work flexible and smart.

If you use computerized knitting factory solutions, you can change designs fast. You can make custom products for sportswear, fashion, or technical textiles. Being flexible helps you stay ahead when people want new things.

Technical Support and Service

Good support helps your machines work well for a long time. You need help with regular checks, fixing problems, and getting new parts. Top companies give strong service plans.

Here is a table with support from leading companies:

|

Manufacturer |

Type of Support |

Description |

|---|---|---|

|

Sintelli |

Fast help, quick answers, and free spare parts delivery. |

Look for companies that give:

-

Regular machine checks

-

Fixing and repair

-

Parts replacement

Strong support means your machines stop less and work more. If something breaks, you get help fast. This keeps your factory running and helps you fill orders for knitted goods.

Tip: Pick companies with good service and support. This helps you keep up with orders and make high-quality products.

Sustainable Textile Production Practices

Factories use more green ways to make textiles every year. Top companies build knitting equipment that helps you use eco-friendly materials. These machines help you save energy. You can pick machines that work with recycled yarns and organic fibers. This lets you follow new trends and meet what customers want for green products.

Here is a table that shows how top manufacturers focus on sustainability:

|

Sustainability Practice |

Description |

|---|---|

|

Eco-friendly materials |

Machines support eco-friendly fibers and recycled yarns. |

|

Energy efficiency |

Designs reduce energy use and lower carbon emissions. |

|

Waste reduction |

Machines help you use less material and make less waste. |

|

Compliance with regulations |

Companies follow global rules and meet demand for green products. |

Many factories use AI in their computerized knitting factory. AI checks where materials get wasted. It helps you use less yarn and energy. AI also makes weaving, knitting, and finishing better. This saves money and helps the planet.

You can use computerized seamless knitting machine models and circular knitting machines. These machines help you make products with almost no waste. You can make custom items and use only the yarn you need. Smart technology in industrial knitting equipment helps you be more green.

Note: Customers want you to use green ways now. If you want to stay ahead, you need knitting machines that help the environment.

Cost and Value

When you look at industrial knitting equipment, check price and what you get. Some machines cost less but may not last long or work well. Other machines cost more but have more features and better results. Think about what your factory needs and what products you want to make.

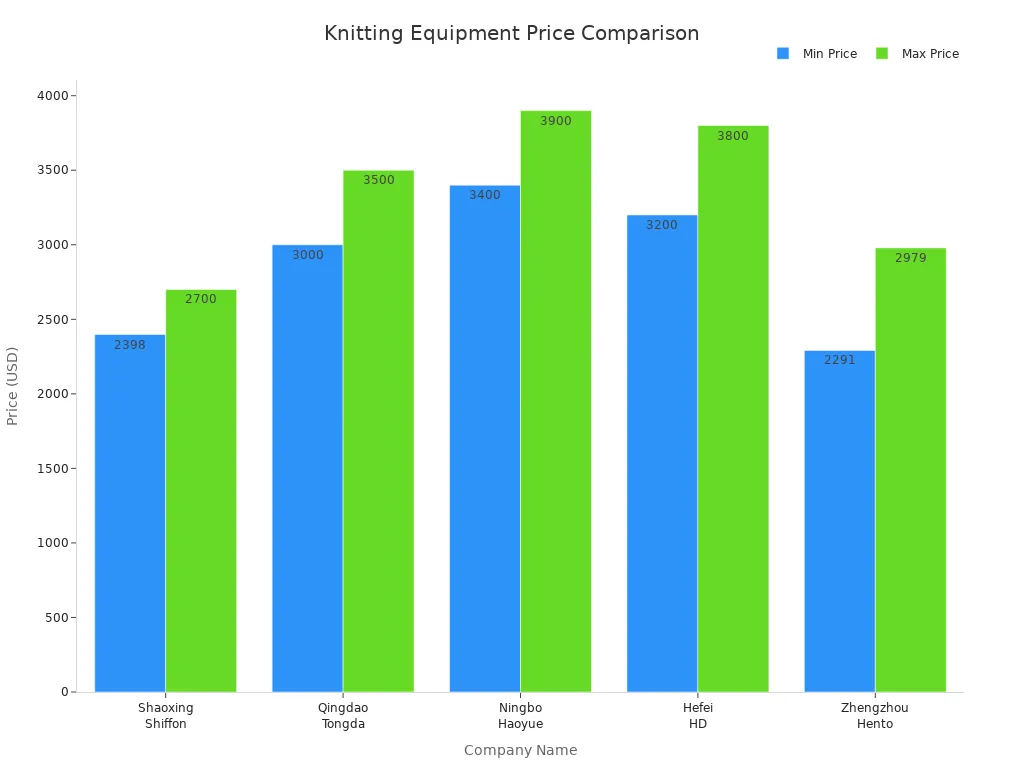

Here is a table that shows the price range and key features of popular knitting machines:

|

Company Name |

Price Range (USD) |

Key Attributes |

Review Score |

|---|---|---|---|

|

Shaoxing Shiffon Textile Co., Ltd. |

$2,398 – $2,700 |

High Speed, Plain |

5.0 |

|

Qingdao Tongda Textile Machinery |

$3,000 – $3,500 |

3D Plain/Terry, Invisible Seam, High Speed |

5.0 |

|

Ningbo Haoyue Textile Tech |

$3,400 – $3,900 |

Plain & Jacquard, Single Cylinder |

4.9 |

|

Hefei HD Machinery Co.,Ltd |

$3,200 – $3,800 |

Fully Computerized, Plain/Invisible |

4.9 |

|

Zhengzhou Hento Machinery |

$2,291 – $2,979 |

Fully Automatic, In Stock |

4.8 |

You can pick budget machines for making lots of plain socks. Shaoxing Shiffon and Shaoxing Rainbowe have good prices for big orders. If you want more features, Qingdao Tongda and Ningbo Haoyue have advanced options and strong reviews. For special needs, Haining Jinhu’s seamless machine gives you top performance.

-

Budget machines help you fill big orders and save money.

-

Mid-range machines give you more choices and better features.

-

High-end machines help you make special products and advanced designs.

Pick machines that match your factory’s size and what you want to make. Think about custom or technical textiles and your long-term plans. Smart choices help you get the best value from your industrial knitting equipment.

Choosing the Right Computerized Knitting Factory Equipment

Assessing Factory Needs

You should first know what your factory needs. Every factory is not the same. Think about what you want to make and how big your factory is. Set your production goals before you pick any equipment. Here are some steps you can use to help you choose:

-

Download specification sheets for new knitting machines. Compare what each machine does with what your factory needs.

-

Watch videos of these machines working in real factories. This helps you see how they work in real life.

-

Talk to experts and ask for advice. They can help you pick the best machine for your factory.

-

Work with specialists to make a plan for your money. This plan shows how fast you can earn back your money.

You should also think about the need for green textiles and custom clothes. If you want to make eco-friendly textiles, check if the machines can use these materials. Advanced technology and automation help you make products faster. They also help you keep up with what people want.

Evaluating Technology Compatibility

You need to check if new knitting systems work with your old machines. This is important for smooth production. Use the table below to help you check:

|

Description |

|

|---|---|

|

Scalability |

The solution should grow with your factory’s needs. |

|

System Compatibility |

The new technology must work with your machine software. |

|

Ease of Use |

Operators should learn quickly and use the machines easily. |

|

Data Security |

Keep your factory’s data safe and protected. |

|

Ongoing Support |

You should get help and advice when you need it. |

Check if new computer-controlled knitting machines connect with your smart factory systems. Make sure seamless knitting machine solutions and circular knitting machines fit with your setup. This helps you avoid problems and keeps your work running well.

Considering After-Sales Support

After you buy knitting equipment, you need good support. Good service helps you fix problems fast and avoid long stops. Look at the table below to see what support matters most:

|

Description |

|

|---|---|

|

Training |

Operators need training to use the equipment well. |

|

Spare Parts Availability |

You need spare parts to fix machines quickly. |

|

Technical Assistance |

You need help for fixing and keeping machines working. |

Ask if the company gives training for your team. Check if spare parts for knitting machines are easy to get. Make sure you can reach technical help when you need it. This support is important for factories with high-speed seamless knitting platforms and advanced automation. Good service helps you meet demand and keep up with new trends in circular knitting machines and energy-saving designs.

Tip: Good after-sales support helps you make quality products and grow your business.

Aligning with Sustainability Goals

You can help your factory be more green by picking smart knitting machines. Many factories now need to make eco-friendly textiles. They also need to use green ways to make things. Your computerized knitting factory should help with these goals. It should also follow the rules for the industry.

Factories do different things to help the planet:

-

Use solar panels to run machines. Solar energy is clean and never runs out. This helps you make less pollution.

-

Use electric presses instead of old presses that use fossil fuels. Electric presses make less bad gas.

-

Get certifications like GOTS, RAF, and GRS. These show your products are made in a green way.

You can do more things to help your factory be greener:

-

Pick energy-saving industrial knitting equipment. These machines use less power and save you money.

-

Use recycled fibers in your products. This helps stop waste and supports a circular economy.

-

Try zero-waste ways to make things. Use all your materials and do not leave leftovers.

The knitting industry is changing quickly. More factories use AI and automation now. These smart systems help you use less and waste less. As more people want green textiles, you need to use good materials and fair ways to make things. This helps you reach your goals and make customers happy.

Circular knitting machines help you make things with less waste. You can use new technology to check how much energy and material you use. This helps you find ways to do better.

Here is a table to help you see if your choices match your green goals:

|

Sustainability Action |

Benefit |

|---|---|

|

Solar Panels |

Lower carbon footprint |

|

Electric Press |

Fewer emissions |

|

Certifications (GOTS, RAF, GRS) |

Meet global standards |

|

Energy-Efficient Machines |

Save power and money |

|

Recycled Fibers |

Reduce waste |

|

Zero-Waste Production |

Use all materials, less leftover |

Tip: When you pick new machines, ask the supplier how their machines help with green production. This helps you do well as more people want green products.

You now know about the best companies for computerized knitting factory equipment. These companies have good technology and machines you can trust. They also help factories be better for the environment. Pick equipment that fits what your factory needs and your green goals. Look at the company profiles and tips to help you choose. This will help your business do well and stay ahead in 2025.

FAQ

What is computerized knitting factory equipment?

Computerized knitting factory equipment uses digital controls to make textiles. You can tell the machine what pattern to knit. These machines work faster than manual ones. They also make fewer mistakes.

How do you choose the right knitting machine for your factory?

Think about what you want to make and your budget. Check if the machine works with your other machines. Ask if it saves energy and if you get help after buying.

Which company leads in seamless knitting technology?

Santoni is the top company for seamless knitting technology. Their machines help you make comfy, high-quality clothes. You also make less waste.

Can you use eco-friendly materials with these machines?

Yes, most new knitting machines use recycled yarns and organic fibers. You can make green products and help the planet.

What support do manufacturers offer after you buy a machine?

Manufacturers give training, spare parts, and technical help. You can get regular check-ups and fast repairs to keep machines working.

How does automation help your factory?

Automation helps you make more with less hand work. You make fewer mistakes and save time. Smart machines also help you watch your production.

Are computerized knitting machines hard to use?

Most machines are easy to use. You can learn with training. Digital screens help you change patterns and settings fast.

What is the lifespan of a computerized knitting machine?

A good machine can last 10 to 15 years if you take care of it. Regular check-ups help your machine last longer.