When you want to get the best deal in the bulk knitwear ordering process, discussing prices can significantly help you save money. By looking at quotes and asking for discounts, you can reduce your costs. Additionally, paying early can lead to even more savings, as many suppliers offer discounts for large orders or prompt payments.

Discount Range | Factors Influencing Discount |

|---|---|

Product type, order volume, payment terms |

Paying on time can help you secure discounts.

Engaging in discussions about payment terms can lead to lower prices.

It’s also important to check how the order ships and whether there are one-stop services available. If suppliers communicate clearly and honestly, you can avoid any unexpected surprises.

Key Takeaways

Talk about prices with suppliers to get discounts and save money on big orders. Pay early so you can get extra savings from many suppliers. Follow clear steps when you order to get your items on time and make sure they are good quality. Always look at quotes from different suppliers to find the best deal for your big order. Know the payment rules so you can handle your money well and not have money problems. Pick suppliers that give one-stop services to make ordering easier and help stop mistakes. Check the minimum order quantities to make sure they fit what your business needs. Ask for a list of all costs so you do not get surprise fees and so everything is clear.

Bulk Knitwear Ordering Process: What Matters Most

Key Steps In The Process

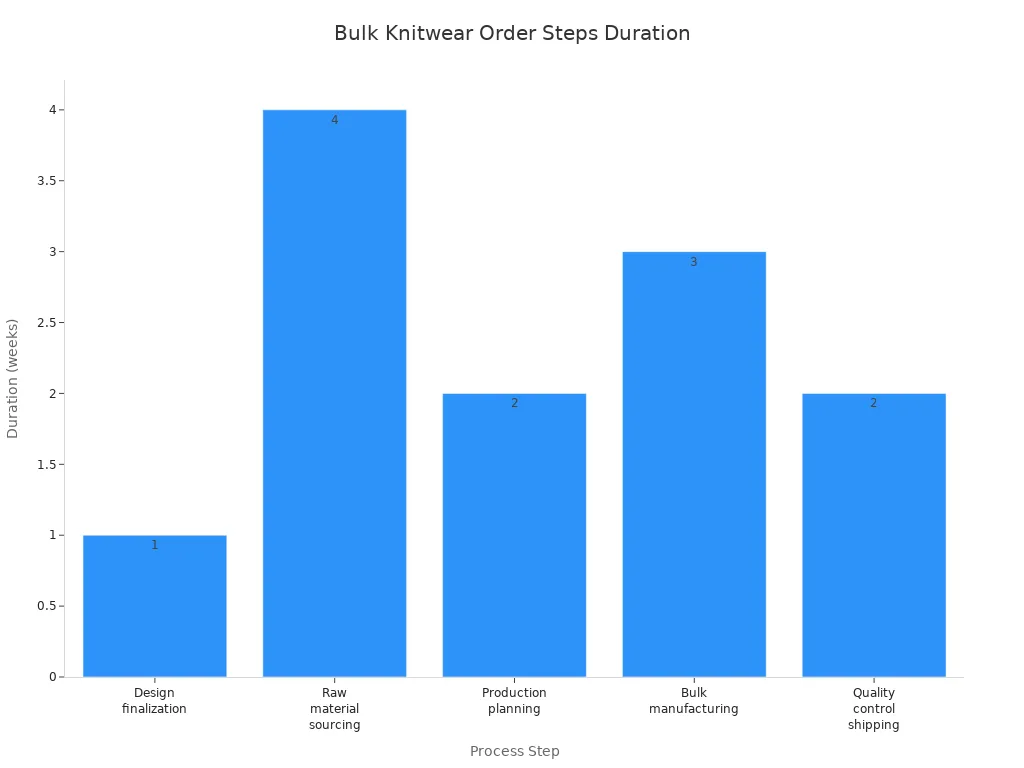

When you start the bulk knitwear ordering process, you need to follow a clear set of steps. Each step helps you move from your first idea to finished products in your hands. Here is a table that shows the main steps and how long each one usually takes:

Step | Duration |

|---|---|

Design finalization and tech pack completion | 1 week |

Raw material sourcing | 4 weeks |

Production planning and sampling | 2 weeks |

Bulk manufacturing | 3 weeks |

Quality control with shipping | 2 weeks |

You begin by finalizing your designs and making sure your tech packs are complete. Next, you source the raw materials. This step often takes the most time. After that, you plan production and create samples. Once you approve the samples, the factory starts bulk manufacturing. The last step is quality control and shipping.

You can also see the process in this chart:

Each part of the bulk knitwear ordering process affects your timeline and your pricing. If you rush any step, you might face problems with quality or delivery.

Comparing Quotes And Discounts

You should always compare quotes from different suppliers before you place a bulk order. Each supplier may offer different pricing based on your order size, design complexity, and the materials you choose. Some suppliers give discounts if you order more pieces or pay early. Others may include extra services in their pricing, like free samples or design help.

Tip: Ask for a detailed breakdown of pricing. This helps you see where you can save money and which supplier offers the best value.

When you compare quotes, look at more than just the lowest price. Check what is included, such as shipping, packaging, and any extra fees. The bulk knitwear ordering process works best when you understand all the costs up front. This way, you avoid surprises later.

Payment Terms And Cash Flow

Payment terms play a big role in the bulk knitwear ordering process. They decide when you pay and how it affects your cash flow. Here is a table of common payment terms you might see:

Payment Term | Description |

|---|---|

Letter of Credit (L/C) | A bank guarantees payment to the seller when you meet certain terms. |

T/T (Telegraphic Transfer) | You pay in advance or after inspection, depending on the agreement. |

Open Account | You pay after you get the goods, usually if you have a strong relationship with the supplier. |

Cash in Advance (CIA) | You pay before production or shipment. |

Net Terms | You pay within a set period, like Net 30 or Net 60, after you get the invoice. |

Flexible payment options can help you manage your cash flow. Some suppliers use invoice factoring, which lets them get paid faster and keep production moving. If you choose the right payment terms, you can keep your business running smoothly and avoid cash shortages.

The bulk knitwear ordering process becomes easier when you know how payment terms and pricing work together. You can plan your orders, manage your money, and build better relationships with your suppliers.

Shipping Logistics And FTL Options

Shipping plays a big role in bulk knitwear orders. You need to know how your sweaters will travel from the factory to your warehouse. Many suppliers offer Full Truck Load (FTL) shipping for large orders. FTL means your goods fill an entire truck, so you get faster delivery and less risk of damage.

FTL rates change based on distance, truck type, and season. Here is a table that shows average rates per mile for different trucks:

Type of Rate | Average Rate per Mile |

|---|---|

National van contract rate | $2.43 |

National flatbed contract rate | $3.14 |

National average reefer rates | $2.81 |

Short local hauls can cost between $700 and $1,000. If you ship sweaters across the country, you might pay more than $5,000. For trips between 500 and 1,000 miles, expect costs in the low-to-mid four figures.

Note: Shipping costs go up in the fall when demand is high. Fuel prices and driver wages also affect the final price.

When you plan your bulk order, ask your supplier about FTL options. You should check if they offer tracking and insurance. These services help you avoid losses and delays. If you order less than a truckload, you may need to share space with other shipments. This can slow down delivery and increase the risk of mix-ups.

You can save money by planning ahead and booking shipping early. If you know your delivery dates, you can avoid peak season rates. Always compare shipping quotes from different suppliers. This helps you find the best deal and keeps your costs low.

One-Stop Services And MOQs

One-stop services make bulk knitwear ordering easier. You get design, sampling, production, and shipping all from one supplier. This saves you time and reduces mistakes. If you work with a supplier who offers everything, you do not need to manage many contacts or solve problems with different companies.

Many suppliers set a Minimum Order Quantity (MOQ). This is the smallest number of pieces you must order. MOQs help factories plan production and keep costs down. Some suppliers set MOQs as low as 100 pieces, while others require 500 or more. You should ask about MOQs before you start your order.

Tip: If you want to test new designs or run a small batch, look for suppliers with flexible MOQs.

One-stop suppliers often help with packaging and labeling. They may offer custom tags, bags, or boxes. You can ask for samples before you place a big order. This lets you check quality and make changes if needed.

When you choose a supplier, ask about their full range of services. You should check if they offer design help, sample making, bulk production, and shipping. If you find a supplier who does it all, you can focus on growing your business and serving your customers.

How We Evaluated Sweaters Wholesale Suppliers

Supplier Selection Criteria

When you pick sweaters wholesale suppliers, you need to check many things. You want each supplier to fit your needs and follow good rules. Here are the main things to look for:

Product quality is very important. You want sweaters that last and look nice.

Profit margin changes your prices and how much you make.

Minimum order quantity helps you plan your money and stock.

Shipping options let you choose how you get your sweaters.

Customer service fixes problems fast and keeps you updated.

Supplier compliance and certifications show they follow fair and green rules.

Production capacity and lead times help you match your order and delivery.

Quality control and assurance keep your sweaters the same every time.

Pricing and cost talks help you get good value.

You should always check suppliers to make sure they meet these things. This step helps you avoid problems and find good manufacturers. If you skip checking, you might have trouble with quality or delivery.

Testing And Evaluation Method

You need a clear way to test sweaters wholesale suppliers. Start by looking at the yarn. Check the color, strength, and if it is clean. Use lab dips to match colors and do random strength checks. Next, ask for samples before production. Look at how the sweaters are made and how they fit. Make sure you say yes before they start making all the sweaters.

Check samples in every size. Use mannequins to see if the fit is good. This step helps you find mistakes in sizing. Before packing, do one last quality check. Look at every sweater using a checklist. Many companies use ERP systems to track these checks. You should also look at supplier reports to make sure they follow your rules.

Testing helps you see which sweaters wholesale suppliers are best for you. If a supplier fails any step, you should ask them to fix things. Good suppliers share their rules and let you see how they check quality.

Metrics For Comparison

You need clear ways to compare sweaters wholesale suppliers. These ways show how well each supplier does. Use the table below to help you check:

Metric | Description |

|---|---|

Shows the percent of orders delivered on or before the date you agreed. | |

Defect Rate | Shows the percent of bad sweaters you get compared to all sweaters you get. |

Lead Time Variability | Shows how steady the delivery times are, so you know if you can trust their schedule. |

You should track these numbers for every supplier. On-time delivery shows if they meet deadlines. Defect rate tells you about quality. Lead time variability helps you plan your stock. Use supplier checks to confirm these numbers. If a supplier has good numbers and clear rules, you can trust them with big orders.

Tip: Always ask for written rules and supplier check papers before you order a lot. This step keeps your business safe and helps you pick the best sweaters wholesale suppliers.

Supplier Reviews: Ordering Experience And Quality

Supplier A: Order Process And Customer Service

Platform Usability

When you order bulk knitwear from Supplier A, the website is simple to use. You can find products and upload your designs easily. It is not hard to check your order status. The dashboard shows each step of your order. You get instructions for every stage, like sending tech packs and confirming samples.

Supplier A’s website lets you look at minimum order quantities, payment choices, and shipping options. You can see how their order process matches what other companies do in the industry.

Aspect | Description |

|---|---|

Minimum Order Quantities | High MOQs mean you pay more up front and might have too much stock. Low MOQs help new brands but make each item cost more. |

Payment Terms | You pick from paying everything up front, paying a deposit and then the rest, or paying later (30/60 days). These choices change how you use your money and work with the supplier. |

Logistics | Shipping inside the country is faster and costs less. Shipping to other countries costs more and can be slowed down by customs. |

You can look at all these choices before you order. This helps you plan your money and your schedule. The website gives you updates right away, so you always know what is happening with your order.

Communication

Supplier A’s customer service team answers your questions fast. You can talk to them by chat, email, or phone. They explain each step and help you fix problems. If you want to change your order or ask about delivery, you get help in a few hours.

The customer service team knows your order details. They help you understand payment choices and guide you through the steps. If you ask about quality control, they connect you with the right people. You feel sure about your order because you get clear answers.

Supplier A sends you messages when your order moves to the next step. You get updates about making, shipping, and delivery. This good communication helps you avoid mistakes and keeps your business working well.

Supplier A: Quality And Packaging

Material Consistency

You want every sweater to be good quality. Supplier A checks quality at every step. They test yarn for color, strength, and if it is clean. You get lab dip results to check the color. The factory checks the materials before making sweaters.

Quality teams look at samples and finished sweaters. They check for problems, bad stitching, and wrong colors. You get a report showing how many sweaters passed or failed. If there are problems, Supplier A fixes them before shipping. This way, you get sweaters you can trust.

Sizing And Presentation

Supplier A makes sure sizing and presentation are right. You get samples in every size before they make all the sweaters. You can check the fit on mannequins or models. If you want changes, Supplier A makes them fast.

Quality teams measure each sweater to check the size. They use a checklist to look at packaging, tags, and labels. You can ask for special packaging, like bags or boxes with your brand. Supplier A packs sweaters neatly so they do not get damaged.

The final look matches your brand’s style. Sweaters come clean, folded, and ready to sell. This careful work helps you impress customers and build trust.

Supplier A: Delivery And Pricing Transparency

Shipping Speed

Supplier A gives you different shipping choices for bulk orders. You can pick shipping inside the country or to other countries. Shipping inside the country is faster and costs less. Shipping to other countries takes longer because of customs.

Supplier A lets you track your shipment in real time. You see updates on your dashboard and get emails. If there are delays, customer service tells you and helps you fix it. This clear information helps you plan your stock and avoid running out.

Tip: Book shipping early to avoid delays and higher prices.

Bulk Discounts And Fees

Supplier A shows you all the details about bulk discounts and fees. You talk about prices based on how much you order, how you pay, and how you want delivery. The website shows you all costs, including discounts for paying early or ordering a lot.

You see all fees before you order, like packaging, shipping, and customs. Supplier A uses one system to share good data with you and other partners. This clear information helps you avoid surprises and plan your money.

You see your orders in real time.

You can spot problems and fix them before they cause delays.

You work better with Supplier A because you share good information.

Bulk orders can be tricky with prices and shipping. Supplier A’s system helps stop mistakes and delays. You get a smooth ordering process and strong customer service.

Supplier B: Order Process And Customer Service

Platform Usability

Supplier B’s website is simple to use. The homepage has clear groups for knitwear styles. You can upload your designs and pick colors easily. The order dashboard shows each step of your bulk order. You see updates for design approval, sample requests, and production. Supplier B gives you a checklist for every step. You can check minimum order quantities and payment choices before you order. The website lets you look at shipping options and compare them. If you need help, you can use live chat. The system saves your old orders, so you can order again fast.

Tip: Use the dashboard to watch your order and find delays early.

Communication

Supplier B answers your questions fast. You can talk to their team by email, phone, or chat. The staff explains each step and helps you fix problems. If you want to change your order or ask about delivery, you get answers in a few hours. Supplier B sends you messages when your order moves to the next step. You get updates about sample approval, production, and shipping. The team gives clear instructions for payment and delivery. If you ask about quality checks, they send you reports. You feel sure because you get honest answers and quick help.

Supplier B: Quality And Packaging

Material Consistency

Supplier B checks quality at every step. The factory tests yarn for color and strength before making sweaters. You get lab dip results to check the color. The team checks materials for cleanliness and strength. During production, Supplier B looks at sweaters for stitching and fabric problems. You get a report showing how many sweaters pass the quality checks. If there are problems, the factory fixes them before shipping. You can trust that each sweater meets your quality needs.

Step | Quality Check Method |

|---|---|

Yarn selection | Color and strength testing |

Sample production | Fit and finish inspection |

Bulk manufacturing | Random batch checks |

Final packaging | Cleanliness and folding |

Supplier B uses strict rules to keep quality high. You can ask for extra checks if you want more control.

Sizing And Presentation

Supplier B sends you samples in every size before making all the sweaters. You can test the fit on mannequins or models. If you want changes, the team fixes the patterns fast. The factory measures each sweater to make sure the size is right. You can ask for special packaging for your brand. Supplier B offers custom tags, bags, and boxes. The team packs sweaters neatly to stop damage during shipping. You get sweaters that look clean and professional. Good packaging helps you impress customers and build trust.

Note: Always check samples for size and quality before saying yes to bulk production.

Supplier B: Delivery And Pricing Transparency

Shipping Speed

Supplier B gives you different shipping choices for bulk orders. You can pick shipping inside the country or to other countries. Shipping inside the country is faster and costs less. Shipping to other countries takes longer because of customs. You can track your shipment online. Supplier B gives you delivery times and tracking numbers. If there are delays, the team tells you and helps you fix it. Fast shipping helps you keep your stock full and meet customer needs.

Bulk Discounts And Fees

Supplier B shows you all costs before you order. You see bulk discounts based on order size and payment terms. The website lists fees for packaging, shipping, and customs. You can compare prices and pick the best choice for your business. Supplier B gives discounts if you pay early or order a lot. The team explains how each fee changes your total cost. You do not get surprises because you see every charge before you order. This clear information helps you plan your budget and manage your money.

Discount Type | How You Qualify |

|---|---|

Early payment | Pay before production |

Large order volume | Order more than 500 units |

Seasonal promotions | Order during off-peak times |

Supplier B makes pricing and shipping easy to understand. You work with a supplier who values honesty and clear answers. You get good quality and fair prices for your bulk knitwear orders.

Supplier C: Order Process And Customer Service

Platform Usability

You will find Supplier C’s platform easy to use. The homepage shows all knitwear categories with clear pictures. You can upload your designs with just a few clicks. The order tracker helps you see every step, from design approval to shipping. You do not need to guess what happens next. The platform gives you reminders for important actions, like sample approval or payment deadlines.

Supplier C lets you check minimum order quantities and payment options before you start. You can compare shipping choices on the same page. If you want to reorder, you can use your order history. This saves you time and helps you avoid mistakes. The platform also has a help center with answers to common questions.

Tip: Use the order tracker to spot delays early and keep your project on schedule.

Communication

Supplier C’s customer service team responds quickly. You can reach them by chat, email, or phone. The team explains each step in simple words. If you have a question about your order, you get a clear answer. You can ask about payment, shipping, or design changes. The team sends you updates when your order moves to the next stage.

Supplier C values clear communication. You get alerts for sample approval, production, and shipping. If you need to change your order, the team helps you right away. You can also ask for reports on quality checks. The staff wants you to feel confident about your order.

Supplier C: Quality And Packaging

Material Consistency

Supplier C checks the quality of materials before making your sweaters. The factory tests yarn for color and strength. You get lab dip results to see if the color matches your design. The team looks for clean and strong yarn. During production, Supplier C checks sweaters for even stitching and fabric problems. You get a report that shows how many sweaters pass the quality checks.

Step | Quality Check Method |

|---|---|

Yarn selection | Color and strength testing |

Sample production | Fit and finish inspection |

Bulk manufacturing | Random batch checks |

Final packaging | Cleanliness and folding |

If the team finds a problem, they fix it before shipping. You can trust that each sweater meets your quality needs. Supplier C also lets you ask for extra checks if you want more control. You can see the results before you approve the bulk order.

Sizing And Presentation

Supplier C sends you samples in every size before making all the sweaters. You can test the fit on mannequins or models. If you want changes, the team updates the patterns quickly. The factory measures each sweater to make sure the size is right. You can ask for special packaging with your brand name.

Supplier C offers custom tags, bags, and boxes. The team packs sweaters neatly to protect them during shipping. You get sweaters that look clean and professional. Good presentation helps you impress your customers and build trust in your brand.

Note: Always check samples for size and quality before you approve bulk production.

Supplier C: Delivery And Pricing Transparency

Shipping Speed

Supplier C gives you several shipping choices for bulk orders. You can pick local or international delivery. Local shipping is faster and costs less. International shipping takes more time because of customs. You can track your shipment online. Supplier C gives you delivery times and tracking numbers.

If there are delays, the team tells you right away. Fast and clear updates help you plan your stock and avoid running out. You can ask for express shipping if you need sweaters quickly.

Bulk Discounts And Fees

Supplier C shows you all costs before you order. You see bulk discounts based on order size and payment terms. The website lists fees for packaging, shipping, and customs. You can compare prices and pick the best option for your business.

Supplier C gives discounts if you pay early or order a large quantity. The team explains how each fee changes your total cost. You do not get surprises because you see every charge before you order. This clear information helps you plan your budget and manage your money.

Discount Type | How You Qualify |

|---|---|

Early payment | Pay before production |

Large order volume | Order more than 500 units |

Off-season deals | Order during slow months |

Supplier C makes pricing and shipping easy to understand. You work with a supplier who values honesty and clear answers. You get good quality and fair prices for your bulk knitwear orders.

Supplier D: Order Process And Customer Service

Platform Usability

You will find Supplier D’s platform easy to navigate. The homepage displays knitwear categories with clear images. You can upload your designs with a few clicks. The order tracker shows each step, from design approval to shipping. You do not need to guess what happens next. The platform sends reminders for sample approval and payment deadlines.

Supplier D lets you check minimum order quantities and payment options before you start. You can compare shipping choices on the same page. If you want to reorder, you can use your order history. This saves you time and helps you avoid mistakes. The help center answers common questions and guides you through the process.

Tip: Use the order tracker to spot delays early and keep your project on schedule.

Communication

Supplier D’s customer service team responds quickly. You can reach them by chat, email, or phone. The team explains each step in simple words. If you have a question about your order, you get a clear answer. You can ask about payment, shipping, or design changes. The team sends you updates when your order moves to the next stage.

Supplier D values clear communication. You get alerts for sample approval, production, and shipping. If you need to change your order, the team helps you right away. You can also ask for reports on quality checks. The staff wants you to feel confident about your order.

Supplier D: Quality And Packaging

Material Consistency

Supplier D checks the quality of materials before making your sweaters. The factory tests yarn for color and strength. You get lab dip results to see if the color matches your design. The team looks for clean and strong yarn. During production, Supplier D checks sweaters for even stitching and fabric problems. You get a report that shows how many sweaters pass the quality checks.

Step | Quality Check Method |

|---|---|

Yarn selection | Color and strength testing |

Sample production | Fit and finish inspection |

Bulk manufacturing | Random batch checks |

Final packaging | Cleanliness and folding |

If the team finds a problem, they fix it before shipping. You can trust that each sweater meets your quality needs. Supplier D also lets you ask for extra checks if you want more control. You can see the results before you approve the bulk order.

Sizing And Presentation

Supplier D sends you samples in every size before making all the sweaters. You can test the fit on mannequins or models. If you want changes, the team updates the patterns quickly. The factory measures each sweater to make sure the size is right. You can ask for special packaging with your brand name.

Supplier D offers custom tags, bags, and boxes. The team packs sweaters neatly to protect them during shipping. You get sweaters that look clean and professional. Good presentation helps you impress your customers and build trust in your brand.

Note: Always check samples for size and quality before you approve bulk production.

Supplier D: Delivery And Pricing Transparency

Shipping Speed

Supplier D gives you several shipping choices for bulk orders. You can pick local or international delivery. Local shipping is faster and costs less. International shipping takes more time because of customs. You can track your shipment online. Supplier D gives you delivery times and tracking numbers.

If there are delays, the team tells you right away. Fast and clear updates help you plan your stock and avoid running out. You can ask for express shipping if you need sweaters quickly.

Bulk Discounts And Fees

Supplier D shows you all costs before you order. You see bulk discounts based on order size and payment terms. The website lists fees for packaging, shipping, and customs. You can compare prices and pick the best option for your business.

Supplier D gives discounts if you pay early or order a large quantity. The team explains how each fee changes your total cost. You do not get surprises because you see every charge before you order. This clear information helps you plan your budget and manage your money.

Discount Type | How You Qualify |

|---|---|

Early payment | Pay before production |

Large order volume | Order more than 500 units |

Off-season deals | Order during slow months |

Supplier D makes pricing and shipping easy to understand. You work with a supplier who values honesty and clear answers. You get good quality and fair prices for your bulk knitwear orders.

Supplier Trust And Flexibility In Bulk Orders

Transparency In Pricing And Production

You need to trust your supplier when you order bulk knitwear. Suppliers who show all their prices and how they make sweaters help you plan better. You see every cost, like yarn and shipping, so you know where your money goes. This open way of working helps you trust them and stops hidden fees.

Here is how top suppliers show their prices:

Component | Description |

|---|---|

Production Cost | Includes sustainable yarn, developer time, machine operator time, knitting time, labeling, and logistics. |

Company Cost | Covers designer time, sampling, marketing, and platform costs. |

Pricing Philosophy | Emphasizes low markups to avoid inflated prices and ensure fair wages for workers. |

Suppliers who share these details help you make smart choices. You can ask questions and get clear answers. When you trust your supplier, you can grow your brand and not worry about surprise costs.

Tip: Always ask for a full list of costs before you order. This helps you spot extra charges and builds trust with your supplier.

Flexibility For New Designs And Seasonal Drops

You want to try new designs or launch seasonal drops. Suppliers who let you order small amounts help you test styles without wasting money or materials. This flexibility keeps your sweater line fresh and helps you follow trends fast.

Suppliers give you lots of ways to customize:

Customization Aspect | Description |

|---|---|

Fabric Types | Options include cotton, wool, acrylic, and blends |

Design Elements | Custom logos, embroidered patches, specialized stitching, and distinctive patterns |

Production Scale | Ability to produce both small and large quantities, accommodating new designs and seasonal drops |

Suppliers with low MOQs help you avoid waste.

You can test new styles without spending a lot.

You keep your sweater line new and fun.

Some suppliers use platforms like Knitup. You can order small batches and see what customers like before you order more. This way, you do not make too many sweaters and can change colors or styles quickly. You build trust with your customers by offering new products they want.

Return And Exchange Policies

Returns are part of bulk orders. You need clear rules so you know what happens if something goes wrong. Top suppliers make returns and exchanges easy to understand. You must start returns within 7 days after you get your order. Items must be unworn, unwashed, and have their tags.

Policy Type | Details |

|---|---|

Return Timeframe | Returns must be initiated within 7 days of receiving the item. |

Condition for Returns | Items must be unworn and unwashed with original tags attached. |

Shipping Responsibility | Buyers are responsible for shipping costs for returns. |

Return shipping costs depend on where you live. Here is a quick look:

Region | Return Shipping Cost | Conditions |

|---|---|---|

USA | $15 | Return shipping costs apply; conditions for returns specified. |

Europe | €15 | Return shipping costs apply; conditions for returns specified. |

Australia | AUD $25 | Return shipping costs apply; conditions for returns specified. |

Asia | £20 | Return shipping costs apply; conditions for returns specified. |

If your return passes inspection, you may get an exchange or store credit. You pay your own shipping and any customs fees for international orders. Suppliers who explain these rules clearly help you trust them. You feel sure about what happens if you need to return something.

Note: Always check the return policy before you order. This protects your business and helps you manage your stock and money.

Choosing The Right Wholesale Clothing Supplier

Matching Supplier Strengths To Business Needs

You want a supplier who fits your business goals. Every supplier is good at different things. Some focus on making high-quality sweaters. Others work fast or let you change designs. You should check how each supplier handles orders. Look at the help they give you. The table below shows what to compare:

Description | |

|---|---|

Quality Control | Suppliers should provide test results and certifications to ensure product quality. |

Communication | Good communication is essential for updates and responsiveness. |

Customization | Suppliers should offer customization options to meet specific bulk needs. |

If you want sweaters with special designs, pick a supplier who lets you customize. If you need your order on time, choose one who gives good updates and tracking. Always look at price and quality together. This helps you get the most for your money. Suppliers with fair prices and good service help your business grow.

Questions To Ask Before Ordering

Before you order bulk knitwear, ask important questions. These questions help you avoid problems and find the best supplier:

What Fabrics Do You Specialize In?

What Are Your Minimum Order Quantities (MOQs)?

What Are Your Lead Times?

How Do You Ensure Quality Control?

What Are Your Terms For Pricing And Payment?

Are the Fabrics Ethically and Sustainably Sourced?

What is Your Shipping and Logistics Process?

Do You Provide Post-Sale Support?

Do You Have A Proven Track Record?

Ask about service at every step. Good suppliers answer your questions and explain their process. You want to know how they handle orders, returns, and help after delivery. If a supplier gives clear answers, you can trust them.

Tip: Write your questions before you talk to a supplier. This helps you compare their service and pick the best one.

Red Flags To Avoid

Watch for warning signs when you pick a bulk knitwear supplier. Some red flags mean poor quality or lost money. The table below shows common problems:

Red Flag | What It Means |

|---|---|

Unrealistic pricing | Possible counterfeits or poor quality |

No samples offered | Hidden quality issues |

Lack of certifications | Ethical or quality shortcuts |

If a supplier does not give samples, you may get sweaters that are not good. Suppliers without certifications may not follow good rules. You should also avoid suppliers who do not explain their service or prices. Always pick suppliers who are open and honest.

You can find the best supplier by looking for good service, clear answers, and fair prices. When you match supplier strengths to your needs, ask smart questions, and avoid red flags, your business will do well with every order.

There are lots of ways suppliers handle bulk knitwear orders. Some suppliers ship orders quickly. Others let you order smaller amounts. You need to pick a supplier that fits your business needs. This helps you feel happier with your order. If you want to be happy with your order, choose a supplier who explains things well and shows all prices clearly. You will feel better if you ask questions and look for warning signs before you buy.

How happy you are depends on how you use the tips in this guide. Make smart choices to get better results with your next bulk order.

FAQ

What should you look for when choosing suppliers for bulk knitwear?

You need to check if suppliers are honest. Look for clear prices and good support. Read customer reviews to see what others think. Compare shipping choices and ask about how long production takes. Always read reviews before you pick a supplier.

How do suppliers handle quality assurance for bulk orders?

Suppliers use strong quality checks. You get samples, lab tests, and final checks. Ask for reports and pictures from your supplier. Good suppliers fix problems before sending your order. Always check quality before you say yes to your order.

Why do customer reviews matter when picking a supplier?

Customer reviews show how suppliers treat buyers. You learn about shipping speed and product quality. Reviews tell you if suppliers keep their promises. Read reviews to avoid problems and find the best supplier for you.

What shipping options do suppliers offer for bulk knitwear?

Suppliers offer local and international shipping. You can pick fast or regular delivery. Some suppliers give tracking and insurance. Good shipping helps you avoid delays. Ask about costs and delivery times before you order.

How do suppliers set minimum order quantities (MOQs)?

Suppliers set MOQs based on what they need to make. You must order a certain number of pieces. Some suppliers let you order fewer for new designs. Ask about MOQs before you start your order.

What is the best way to compare suppliers?

Use tables to compare suppliers. Look at quality checks, shipping, reviews, and prices. Ask for sample products to see quality. Make a list of good and bad points for each supplier. This helps you pick the best one for your business.

How do suppliers handle returns and exchanges?

Suppliers have easy-to-understand return rules. You must send items back within a set time. Products must be new and have tags. You pay for shipping when you return items. Read the supplier’s rules before you order.

Why is supplier transparency important?

Supplier transparency helps you trust them. You see all costs and how things are made. Honest suppliers answer questions and share reports. Pick suppliers who show clear information and explain their process.