If you want to choose the best viscose sweater oem supplier, you should not only look at prices. You need to see how the factory works. You should check how they deal with changes in materials. It is important to know if they use safe and eco-friendly ways. Many companies have trouble being open about their supply chain. They also find it hard to keep their promises about being sustainable. Some suppliers use old ways that harm the environment. Others have a hard time because of strong competition. Some cannot find enough skilled workers. Make sure your supplier talks with you clearly. They should also meet the standards that matter to you.

Key Takeaways

-

Do not just look at prices when picking a viscose sweater OEM supplier. Check how they make sweaters and if they care about the environment.

-

Know the difference between OEM and ODM. OEM lets you make your own designs. ODM gives you sweaters that are already made.

-

Look at how many sweaters the supplier can make. Make sure they can make the number you need. See if their workers have good skills.

-

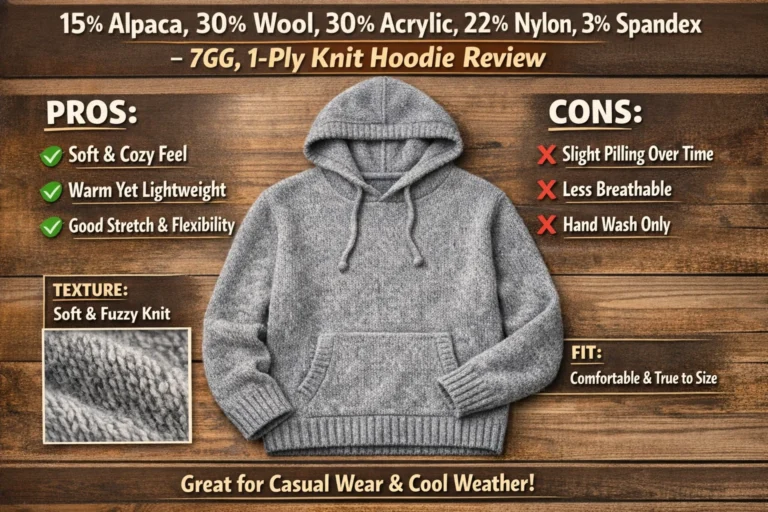

Ask about the fabric quality. Sweaters with more threads and eco-friendly materials are better.

-

Check for certifications like OEKO-TEX and GOTS. These show the supplier cares about safety and the planet.

-

Ask for samples before you buy a lot. Samples help you check the quality and if the design is right.

-

Talk clearly with your supplier. Good talking helps things go well and fixes problems fast.

-

Use sourcing agents to check the supplier’s background. They help you find good suppliers and avoid mistakes.

Viscose Sweater OEM Supplier Overview

What Is OEM?

You might hear the term OEM a lot when you look for sweater suppliers. OEM stands for Original Equipment Manufacturer. This means you work with a factory that makes products based on your own designs and ideas. You get to choose the style, color, and even the label. The oem clothing manufacturer follows your instructions and produces sweaters that match your brand. Many fashion brands use oem clothing manufacturing to create unique collections. You control the look and feel of your sweaters, and the supplier handles the production.

Why Viscose for Sweaters?

Viscose is a popular choice for sweaters. You probably want your sweaters to feel soft and look bright. Viscose gives you both. Here are some reasons why viscose works well for sweater production:

-

Softness and Comfort: Viscose feels smooth, almost like silk. You get a cozy sweater that feels good against your skin.

-

Drapability: Viscose hangs nicely. Your sweaters look elegant and stylish.

-

Vibrancy of Color: Viscose absorbs dye well. You see bright, long-lasting colors in your sweaters.

-

Breathability: Viscose lets air flow. You stay cool in warm weather.

-

Thermal Properties: Viscose keeps you warm when it gets cold.

You can offer sweaters that look great and feel comfortable. Your customers will notice the difference.

OEM vs ODM

You might wonder about the difference between OEM and ODM. Both options help you create sweaters, but they work in different ways. OEM lets you design your own products. ODM means you pick from ready-made designs the supplier already has.

Here is a simple table to show how costs compare:

|

Aspect |

OEM |

ODM |

|---|---|---|

|

Higher due to custom design and tooling |

Lower due to ready-made designs |

|

|

Production Costs |

Higher due to R&D and prototyping |

Lower as costs are spread across clients |

|

Financial Commitment |

Greater long-term commitment required |

Less commitment, more flexibility |

If you choose OEM, you spend more at first. You pay for research, design, and special tools. You get a sweater that matches your brand exactly. If you choose ODM, you save money at the start. You pick from designs that many clients use. The supplier spreads the cost, so you pay less. You get more flexibility and less risk.

Tip: If you want full control over your sweater designs, OEM is the way to go. If you want to test the market or save money, ODM might work better for you.

Key Criteria for Choosing a Viscose Sweater OEM Supplier

When you look for a viscose sweater oem supplier, you want to pick the best one. There are some important things you should check first. Let’s look at what matters most so you know what to ask.

Production Capacity & Expertise

Factory Scale

You need a supplier who can handle your order size. Some factories have many weaving machines. They can make over 120,000 meters of fabric each day. If you want your business to grow, pick a supplier with enough space and machines. Ask them about their equipment. Find out how many sweaters they can make each month. Sourcing agents can help you see if the factory is big enough for you.

Technical Skills

Size is not the only thing that matters. You also need a team with good technical skills. The best oem clothing manufacturer uses new machines and skilled workers. They know how to use viscose yarn. They can make sweaters that look and feel nice. Ask about their experience with oem clothing manufacturing. Sourcing agents can check if the factory has the right skills. You can also ask about their staff training and how they make sweaters.

Tip: Ask for a tour of the factory or a video call. You can watch how they work and ask about their skills.

Fabric Quality Standards

Thread Count

Thread count is important for soft and strong sweaters. High thread count means the fabric feels smooth and lasts longer. Ask your supplier about their thread count. Good suppliers follow strict rules and check quality at every step. They look at every batch to make sure the fabric is good.

Material Sourcing

Where the supplier gets their viscose yarn is important. Good suppliers pick high-quality yarn from trusted places. Sourcing agents can help you check if the supplier uses good vendors. Ask about their supply chain. See if they use eco-friendly or certified yarns. Background checks can show if the supplier follows good sourcing rules.

Here’s a quick table to help you compare fabric quality:

|

Aspect |

What to Look For |

|---|---|

|

Thread Count |

High numbers for softness and durability |

|

Material Sourcing |

Certified, eco-friendly, and traceable |

|

Quality Control |

Rigorous inspection at every stage |

Sustainability & Certifications

OEKO-TEX Certification

You want sweaters that are safe for your customers. OEKO-TEX certification means the fabric has no bad chemicals. This is important for health and safety. Ask your supplier if they have OEKO-TEX 100 certification. It shows they care about chemical safety.

Environmental Compliance

Sustainability is very important now. The best suppliers follow strict environmental rules. They may have certifications like GOTS for organic materials, GRS for recycled content, or FSC for good forest management. These certifications show the supplier cares about the planet and people.

Here’s a table of common certifications you might see:

|

Certification |

Focus |

What It Means |

|---|---|---|

|

OEKO-TEX 100 |

Chemical safety |

No harmful chemicals in finished products |

|

GOTS |

Organic materials |

Organic fibers and strict environmental standards |

|

GRS |

Recycled content |

At least 20% recycled material in products |

|

FSC |

Forest management |

Responsible sourcing from managed forests |

Note: Certifications are important, but you should also ask about real actions. Some suppliers have certificates but do not always follow the best rules. Always ask for proof and ask questions.

If you follow these steps, you can find a viscose sweater oem supplier who fits your needs for making, quality, and caring for the planet. Sourcing agents and background checks help you make sure your supplier is good. Always ask for samples and check certifications before you order a lot.

Product Range & Customization

When you pick a viscose sweater oem supplier, you want to know how much you can change your products. You might want sweaters that match your brand or offer something new. Let’s see how you can get the most from your supplier.

Design Flexibility

You can ask your oem clothing manufacturer for many changes. Some suppliers let you change almost every part of the sweater. You can pick the fiber, color, and pattern. You can add your own logo or special packaging. This helps you build a strong brand and stand out.

Here’s a table that shows common ways to customize and the smallest order you might need:

|

Customization Type |

Minimum Order Requirement |

|---|---|

|

Customized logo |

50 pieces |

|

Customized packaging |

100 pieces |

|

Graphic customization |

50 pieces |

|

Supplier’s customization ability |

N/A |

|

Minor customization |

N/A |

|

Drawing-based customization |

N/A |

|

Full customization |

N/A |

Some changes need you to order more sweaters. For a custom logo, you may need at least 50 sweaters. For special packaging, you might need 100. Sourcing agents can help you talk to the supplier. They can check what is possible and help you understand what the factory can do.

A good viscose sweater oem supplier helps you from start to finish. You can pick the fiber and add final touches. This means you get sweaters that match your brand and meet your standards. Sourcing agents can help you check if the supplier keeps their promises.

Tip: Ask your supplier if they can use your drawings or ideas. This shows how flexible they are with design.

Sample Requests

Before you order a lot, you should ask for samples. Samples help you check the quality and see if the design is right. You can touch the fabric, look at the stitching, and see the colors. This step is important for oem clothing manufacturing.

Here’s a table that explains why samples matter:

|

Benefit of Sample Requests |

Explanation |

|---|---|

|

Quality Assessment |

Sample requests let buyers check the quality of viscose sweaters before ordering more. |

|

Design Accuracy |

They help make sure the supplier can follow your design. |

|

Informed Decision Making |

Sample development helps you make smart choices about which supplier to pick. |

If you skip this step, you might have problems. Bad product quality can mean more returns. Your brand can look bad if customers get sweaters that are not good. You might lose money if you have to fix mistakes later.

-

You avoid bad product quality.

-

You protect your brand’s good name.

-

You save money by finding problems early.

Sourcing agents can help you ask for samples and check them. They can also help you compare samples from different suppliers. This makes it easier to pick the best one.

Note: Always ask for samples before you decide. Samples show you if the supplier meets your standards.

If you follow these steps, you can find a supplier who gives you the right product range and customization. You get sweaters that match your brand and make your customers happy.

Evaluating China Sweater OEM Supplier Options

When you look for a china sweater oem supplier, you should know what makes one better than others. Picking the right supplier helps your business grow. It also keeps your customers happy. Let’s see what you need to check.

Supplier Reputation

You want a supplier people trust. This means they have a good history. Some things help build a good reputation:

-

Many years working in the industry. For example, Shanghai Jason Textile Co., Ltd. has 25 years of experience selling ladieswear fabrics.

-

Working with big brands like ZARA, H&M, and GAP. These brands trust them, so you can too.

-

Making high-quality textile fabrics for local and international brands.

If you see these things, the china sweater oem supplier is serious about their work. Sourcing agents can help you check their background. You can also use background checks to make sure the supplier is honest.

Communication & Responsiveness

Good communication makes things easier. You want a supplier who answers fast and keeps you updated. If there is a problem, they should tell you and help fix it.

Good communication is very important for a successful OEM partnership, especially with international suppliers. A good OEM partner gives updates, solves problems, and listens to feedback.

When you talk to a china sweater oem supplier, see how fast they reply. Do they answer your questions clearly? Do they listen to your ideas? Sourcing agents can help you test how fast a supplier responds before you order.

Cost & Shipping

You need to know how much you will pay and how your sweaters will get to you. China sweater oem supplier options have different prices and shipping ways.

Pricing Models

Here’s a table to help you compare pricing models:

|

Pricing Model Type |

Price Range |

Characteristics |

|---|---|---|

|

Lower-Priced Items |

$13.50–$17.50 |

Simple process, some customization, good for new private labels |

|

Higher-Cost Pieces |

$25.99+ |

Special fibers, detailed designs, bigger orders, good for premium collections |

|

Flexible MOQs |

Starting at 2 pieces |

Lets you test the market with small orders, but costs more per sweater |

Some suppliers let you order just a few sweaters to try new ideas. Others want bigger orders but give better prices. If you want to test new designs, flexible MOQs help you start small.

Shipping Solutions

Shipping is important when working with a china sweater oem supplier. Ask about their shipping partners and how long it takes. Some suppliers ship small orders fast. Others use bulk shipping for big orders to save money. A good oem clothing manufacturer helps you pick the best shipping for your needs.

If you want no surprises, ask for clear shipping costs and delivery times. This helps you plan and keeps your customers happy.

Choosing the right china sweater oem supplier means looking at reputation, communication, cost, and shipping. Sourcing agents and background checks help you find the best partner. When you work with a trusted viscose sweater oem supplier, you get good products and feel safe. Oem clothing manufacturing is easier with the right team.

Quality Assurance & Compliance

When you pick a viscose sweater supplier, you want good sweaters. Quality assurance and compliance help you get sweaters that last. Let’s see how top suppliers keep their promises.

In-House Quality Control

Great suppliers use strong quality control systems. These systems check every step. You want a supplier who plans each stage. They train their staff well. They follow clear rules. Here’s what you should look for:

-

The supplier plans each step of the process.

-

Staff learn to spot problems early.

-

The factory checks for mistakes during and after making sweaters.

-

They test and inspect sweaters before shipping.

You can ask your oem clothing manufacturer about their quality control. Good suppliers show you their rules and explain their steps. If you see a clear plan, you know they care about your brand.

Tip: Ask for their quality benchmarks or a sample inspection report. This helps you see how much they care about quality.

Third-Party Audits

Sometimes, you want extra peace of mind. Third-party audits give you an outside view. These audits check if the supplier follows the rules. Many brands use outside companies for these checks. This makes the process fair and open.

A third-party audit can look at:

-

How the supplier handles materials.

-

If the staff follow safety rules.

-

If the finished sweaters match your order.

You can ask your supplier about recent audits. You can also hire your own auditor to visit. This step helps you avoid surprises and builds trust.

Regulatory Compliance

You need to know if your supplier follows the law. Good suppliers meet all local and international rules. They follow safety, labor, and environmental standards. This protects your business and your customers.

Here’s a simple table to help you check compliance:

|

Compliance Area |

What to Ask For |

|---|---|

|

Product Safety |

Certificates for safe materials |

|

Labor Standards |

Proof of fair working conditions |

|

Environmental Laws |

Records of eco-friendly practices |

If your supplier meets these rules, you can sell your sweaters with confidence. You avoid legal trouble and show your customers you care.

Quality assurance is not just about checking the final product. It covers every step, from planning to shipping. When you work with a supplier who takes quality control and compliance seriously, you protect your brand and keep your customers happy. In oem clothing manufacturing, these steps make all the difference.

Making the Final Supplier Decision

Picking your viscose sweater oem supplier is important. You should feel sure before you sign anything. Let’s look at the last steps so you can choose well for your brand.

Comparing Shortlisted Suppliers

You may have a few suppliers you like. Now, compare them side by side. Check how each one fits your needs. Look at their production, reputation, and quality. Here’s a table to help you keep track:

|

Description |

|

|---|---|

|

Production Capacity and Scalability |

Can the supplier handle your orders now and later? Check their factory size and how many people work there. |

|

Reliability Metrics |

Do they have good skills, strong quality checks, and certifications like Oeko-Tex or GOTS? |

|

Communication Responsiveness |

Do they answer your questions fast? Are they clear when you talk about deals? |

You want a supplier with a good name. Ask who they worked with before. Look for reviews from other buyers. Use background checks to make sure they tell the truth. If a supplier does well in all areas, they are a good choice.

Tip: Make a scorecard for each supplier. This helps you see which one is best.

Sample Evaluation

Samples show you what you will get. Do not skip this step. Here is how to check each sample:

-

Measurement: See if the sweater matches your size.

-

Construction: Check the stitching. Is it neat and strong?

-

Materials & Finishing: Touch the fabric. Is it soft and smooth? Are the finishing touches clean?

-

Fit & Functionality: Try the sweater on. Does it fit well? Is it comfy?

-

Feedback: Write down what you like and what needs work.

If you find problems, talk to the supplier. Good suppliers want to fix things and help you. This step helps you avoid bad surprises and keeps your brand strong.

Final Checklist

Before you choose, go through this checklist. It covers what you need for a safe order:

-

Special needs and on-site tests

-

Thread ends

-

Stains, mold, smell, and bugs

-

Measurements

-

Stitches

-

Order details

-

Broken pins or human hairs

-

Fabric problems

-

Color changes

-

Packaging, labels, and marks

-

Rub and wash tests

-

Random product checks

-

First production check

-

In-line check

-

DUPRO check (during making)

-

Supplier check (factory visit)

-

Social check (ethical rules)

Check each thing carefully. If you find a problem, ask the supplier to fix it before you order more. This keeps your brand safe and your customers happy.

Note: A good checklist helps you find problems early. You save money and avoid trouble later.

If you follow these steps, you can pick a viscose sweater oem supplier who meets your quality needs and has a good name. Use background checks and sample reviews to help you choose the best partner for your business.

You want to find the best viscose sweater OEM supplier for your brand. Here are some steps you should take:

-

Check if the supplier has business licenses and certifications.

-

Go to the factory and look at their machines and sample room.

-

Make sure they know how to export and have the right papers.

-

Ask how long it takes to get samples. Five to seven days is best.

-

Set a minimum order amount that works for you.

-

Visit the factory to see how they work and meet their team.

Picking a supplier who cares about the planet helps your brand grow. You can use eco-friendly materials like Modal or recycled viscose. This makes your customers happy and keeps them coming back.

Be careful of common mistakes:

|

Mistake |

Explanation |

|---|---|

|

Lack of Transparency |

Some suppliers hide things or skip papers, which causes trust issues. |

|

Contract Mistakes |

If contracts are not clear, you might lose money or rights. |

|

Quality Issues |

If checks are not good, you get bad products and your brand suffers. |

|

Language Barriers |

Not understanding each other can cause big problems. |

Follow these tips and steps to feel sure when picking your supplier. Your brand will be special, and your customers will see the good quality.

FAQ

What makes a china sweater oem supplier different from other suppliers?

You can control your sweater designs and branding. The supplier makes sweaters that match your ideas. You can pick special colors, labels, and packaging.

How do you check the reliability of a china sweater oem supplier?

Look at their past work and client reviews. Ask for references and see if they work with big brands. Visit the factory or use sourcing agents to see how they work.

Can a china sweater oem supplier handle small orders?

Many suppliers let you order just a few sweaters. This helps you test the market. Always ask about their minimum order before you buy.

What certifications should you expect from a china sweater oem supplier?

Look for OEKO-TEX, GOTS, or GRS certifications. These show the supplier cares about safety and the planet. Ask for proof and check if the certificates are up to date.

How long does it take for a china sweater oem supplier to deliver samples?

Most suppliers send samples in five to seven days. You can ask for faster delivery if you need it. Always check the timeline before you order.

What customization options can you get from a china sweater oem supplier?

You can pick your own colors, patterns, logos, and packaging. Some suppliers let you use your drawings or ideas. Ask about their design options and how they make samples.

How do you avoid communication problems with a china sweater oem supplier?

Use simple words and write down all details. Ask for updates often and set clear rules early. Sourcing agents can help if there are language problems.

What shipping solutions does a china sweater oem supplier offer?

You can choose fast shipping for small orders or bulk shipping for big ones. Suppliers work with trusted shipping companies. Always ask about shipping costs and how long delivery takes.