Custom Knitwear Manufacturer Guide - The Complete OEM/ODM Buyer Handbook

Xindi Knitwear Expert

Xindi Knitwear industry specialist sharing OEM/ODM manufacturing knowledge, yarn insights, and sweater production solutions for global fashion brands.

As global fashion brands accelerate product cycles and diversify knitwear categories, partnering with a reliable OEM/ODM knitwear manufacturer has become one of the most strategic choices for DTC labels, fashion houses, retailers, and e-commerce brands.

This guide provides an end-to-end explanation of how custom knitwear is developed, produced, controlled, and delivered—based on real industry processes used by top factories in Dalang, Dongguan, the world’s largest sweater manufacturing hub.

What Is Custom Knitwear Manufacturing?

Custom knitwear manufacturing refers to the process in which a specialized factory transforms a brand’s design concept, sketch, or tech pack into fully finished knitted garments—such as sweaters, cardigans, dresses, tops, and accessories—through OEM or ODM production models.

OEM vs ODM – Key Differences

OEM (Original Equipment Manufacturer)

Brand provides full tech pack / measurements / artwork / pictures

Factory follows exact specifications

Suitable for brands with strong design capabilities

Ensures consistency with brand identity

ODM (Original Design Manufacturer)

Factory provides original designs or seasonal collections

Brand can modify details, colors, yarns

Suitable for smaller brands, startups, and buyers who need quick-to-market styles

Lower development burden

Summary:

OEM = brand-controlled design

ODM = factory-supported design

Which Brands Are Best Suited for OEM/ODM?

DTC brands → Require fast sampling, flexible MOQ, and consistent fit

Boutiques & independent designers → Benefit from ODM ideas and low MOQ

Department stores & retailers → Need scalable capacity, strong QC

Fast fashion brands → Require large daily output, wide yarn sourcing, rapid lead times

Why Global Brands Outsource Knitwear Production

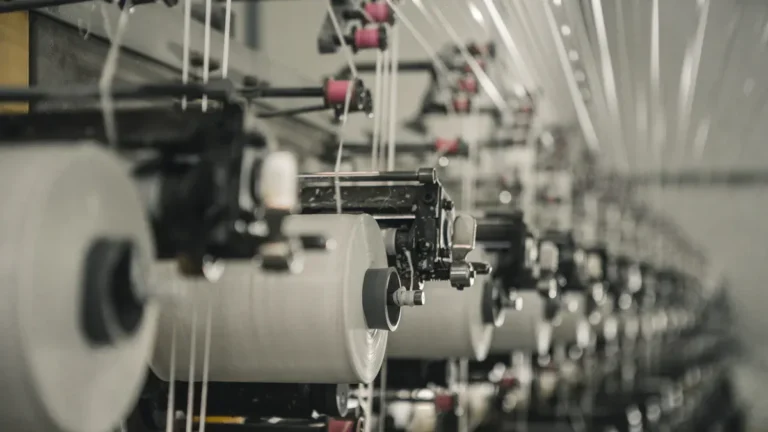

Access to advanced computerized knitting machines (1.5GG–16GG)

Significantly lower production cost compared to in-house manufacturing

Factories handle sourcing, knitting, linking, washing, QC, packing under one system

Our factory offer yarn inventory, reducing lead times

Professional QC teams minimize risk and ensure consistency

Full Knitwear OEM Workflow (From Development to Bulk Production)

Knitwear development follows a structured, technical sequence. Each step affects tension, gauge, sizing stability, and final garment performance.

Step 1 — Tech Pack / Sketch / Inspiration

Brands may submit:

Full tech pack

Photo reference

Physical sample to replicate

Seasonal moodboard or color stories

The factory confirms:

Measurements ( back neck to bottom length, chest width, sleeve length)

Yarn composition

Finishing requirements

Labeling, packing & trims

Step 2 — Yarn Selection (Merino / Cashmere / Cotton / Blends)

Yarn determines:

Handfeel

Weight

Gauge compatibility

Price

Pilling performance

Common choices:

Merino Wool, Mohair , Alpaca (soft, warm, premium)

Cashmere (luxury handfeel, lightweight warmth)

Cotton & Organic Cotton (breathable, all-season)

Acrylic / Blends (cost-effective, stable)

Recycled Yarns (GRS) (eco-friendly, traceable)

Step 3 — Stitch & Gauge Selection (3GG–18GG)

Gauge affects density, weight, and aesthetic.

1.5-3GG: chunky, winter sweaters (boyfriend, oversized styles)

5GG–7GG: mid-weight knitwear

9GG–12GG: classic pullovers

14GG–16GG: fine-gauge premium sweaters

Stitch options:

Cable, jacquard, intarsia, rib, waffle, pointelle, links-links, Milano, etc.

Step 4 — Sampling & Fit Approval

Sampling timeline: 3–5 days for our factory

Fit review includes:

Balance of front/back panels

Armhole shaping

Neck opening

Sleeve pitch

Shrinkage after washing

Ironing

A corrected second sample may be produced before bulk.

Step 5 — Bulk Production (Knitting / Linking / QA)

Bulk stages include:

Knitting – computerized machines execute programmed patterns

Paneling – body, sleeves, collar panels produced separately

Linking – hand-linking or auto-linking for clean seams

Washing – softening, steam blocking, pre-shrink

Finishing – trims, labels, button attachment

In-line QC – tension, density, measurement checks

Step 6 — Final QC + Packing

Final QC ensures:

Correct measurements

Consistent tension

No loose threads

Pilling test results

Color fastness

Clean finishing

Packing includes polybags, brand labels, carton marks.

Step 7 — Export & Shipping (DDP/FOB/EXW)

Common methods:

FOB China port

DDP to USA/EU warehouses

CIF ocean shipment

Air freight for urgent orders

Key Factors Brands Consider When Choosing a Factory

Production Capacity (Machines + Technicians)

Large factories: 100–200+ machines (we have 100+)

Skilled linking workers ensure clean seams

Digital pattern programmers for complex jacquards

Speed of Sampling (3–5 Days)

Faster sampling = faster pre-sales = faster season launch.

MOQ Flexibility

Low-MOQ factories support startup brands (Our moq starts from 50 units)

High-capacity factories handle 10,000+ pcs per style

Yarn Inventory & In-Stock Colors

Available yarn = reduced lead time.

Important for DTC and fast-fashion brands.

How to Choose the Best 3gg Chunky Sweater Manufacturer for Your Brand

Stitch Capability (Jacquard, Intarsia, Cable, Pointelle)

More stitch capability = wider design freedom.

Yarn Options for Custom Knitwear

Wool / Merino Wool

Warm, breathable, high elasticity, luxury performance.

Cashmere

Softest handfeel, premium pricing, excellent insulation.

Cotton / Organic Cotton

Hypoallergenic, breathable, ideal for spring/summer.

Acrylic / Blends

Budget-friendly, stable, easy-care.

Recycled Fibers (GRS Certified)

High demand for sustainability compliance.

Bamboo, Modal, Tencel

Eco-friendly alternatives with smooth, silky handfeel.

Common Custom Knitwear Types

Sweaters

Crewneck, V-neck, mock neck, turtleneck.

Cardigans

Long-line cardigans, cropped styles, heavy-gauge winter options.

Hoodies

Cable knit, waffle knit, double-knit, textured knit, oversized essentials-style, zip-up knitted

Knitwear Dresses & Tops

Rib dresses, polo knits, tank tops, fitted tees.

Accessories

Beanies, scarves, gloves, neck warmers.

Customization Options

Gauge (1.5GG–16GG)

Directly affects weight and texture.

Stitch Types

Cable, waffle, rib, pointelle, jacquard, intarsia.

Silhouette & Fit

Oversized, relaxed, boxy, slim-fit, bodycon.

Trims

Buttons, metal zippers, embroidery, leather patches, woven labels.

Color Options (color cards of yarns)

Pick up color from our yarn color card for your best design.

Check for Fade color Vintage Style (Gradient)

Knitwear Quality Control Checklist

Shrinkage Control

Pre-washing and steam blocking reduce post-wash variance.

Pilling Grade

Tested using Martindale abrasion standards.

Tension Consistency

Ensures uniform texture across panels.

Measurement Tolerance

Typically ±1–2 cm depending on fit.

Color Fastness

Sweat, rubbing, and washing tests ensure durability.

Cost Structure of Custom Knitwear

Yarn Cost

Main cost driver—cashmere > merino > cotton > acrylic.

Craftsmanship Cost (Gauge & Complexity)

Finer gauge = more stitches = higher price

Cable or jacquard = higher workmanship cost

Pattern & Sample Fee

Covers programming, linking, and fit adjustments.

Packaging, Tags, Branding

Custom labels, wash-care tags, woven patches, polybags.

How to Work With a Knitwear Factory

How to Submit a Tech Pack

Include:

Full measurements

Stitch details

Yarn composition

Color references

Label position

Branding elements

Packaging instructions

Sampling Timeline

3–5 working days for first proto.

Common Mistakes

Incomplete tech packs

Missing measurements

Unclear gauge or stitch requirements

Unrealistic timelines

How to Reduce Revisions

Approve yarn before sampling

Confirm gauge early

Provide reference sample if possible

Approve fit on mannequin or model

Case Studies (2025)

Zara Sample Recreation

Recreating a jacquard cardigan with precise tension, colorwork, and measurements.

Low-MOQ Startup Brand (Norway Influencer Brands)

ODM-driven development to launch a full 20-piece (S – M – L size) knitwear collection under low MOQ.

Jacquard Holiday Sweater Project (EU Xmas Ugly Sweaters)

5000+ pcs delivered in 3 weeks using computerized jacquard knitting.

FAQs

MOQ varies by yarn, but typically 50–100 pcs per color for most styles.

Yes, sample fees cover yarn, programming, shipping and labor. For common design, total cost will be 80~100(include air shipping cost).

FOB, DDP, CIF, and air freight available.